© 2015 Thorlabs

1 General Information

3

1 General Information

The Thorlabs TED200C Thermoelectric Temperature Controller is aprecise temperature

controller for laser diodes and detectors.

The TED200C is excellently suited for:

·wavelength stabilization of laser diodes

·noise reduction of detectors

·laser diode's wavelength tuning by regulating the temperature

·modulation of wavelength by tuning the temperature

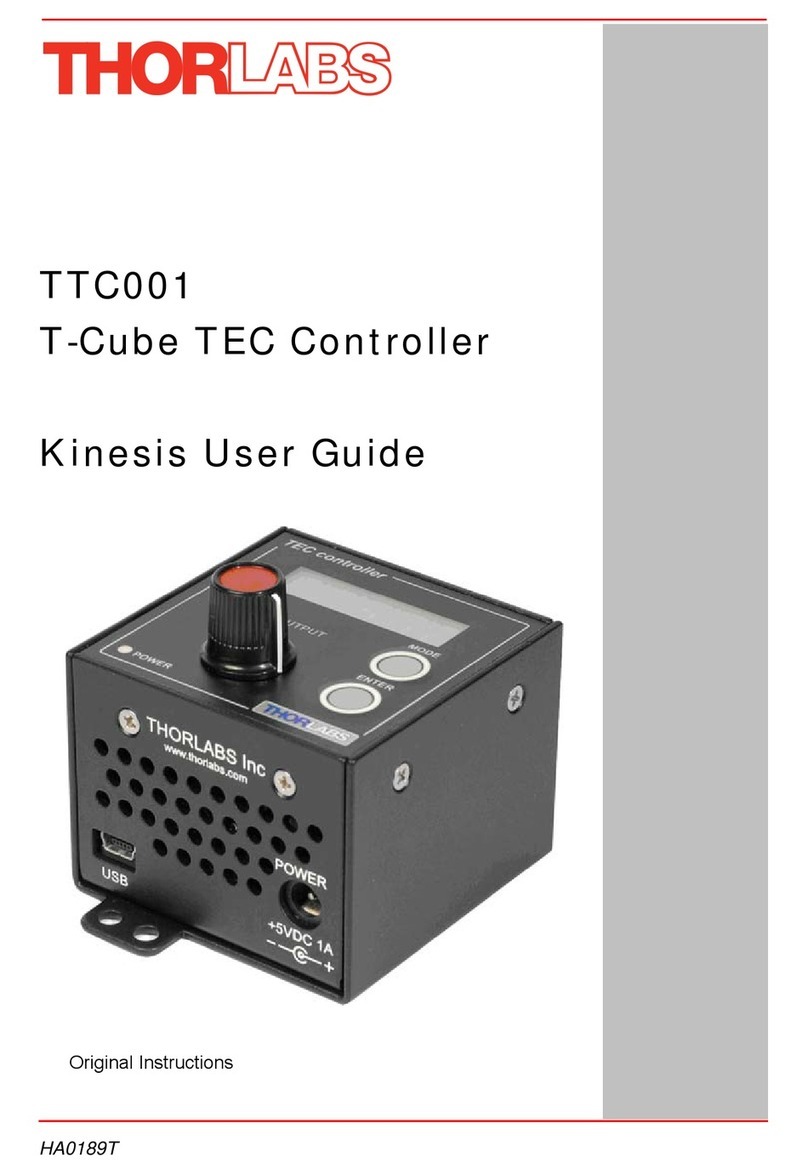

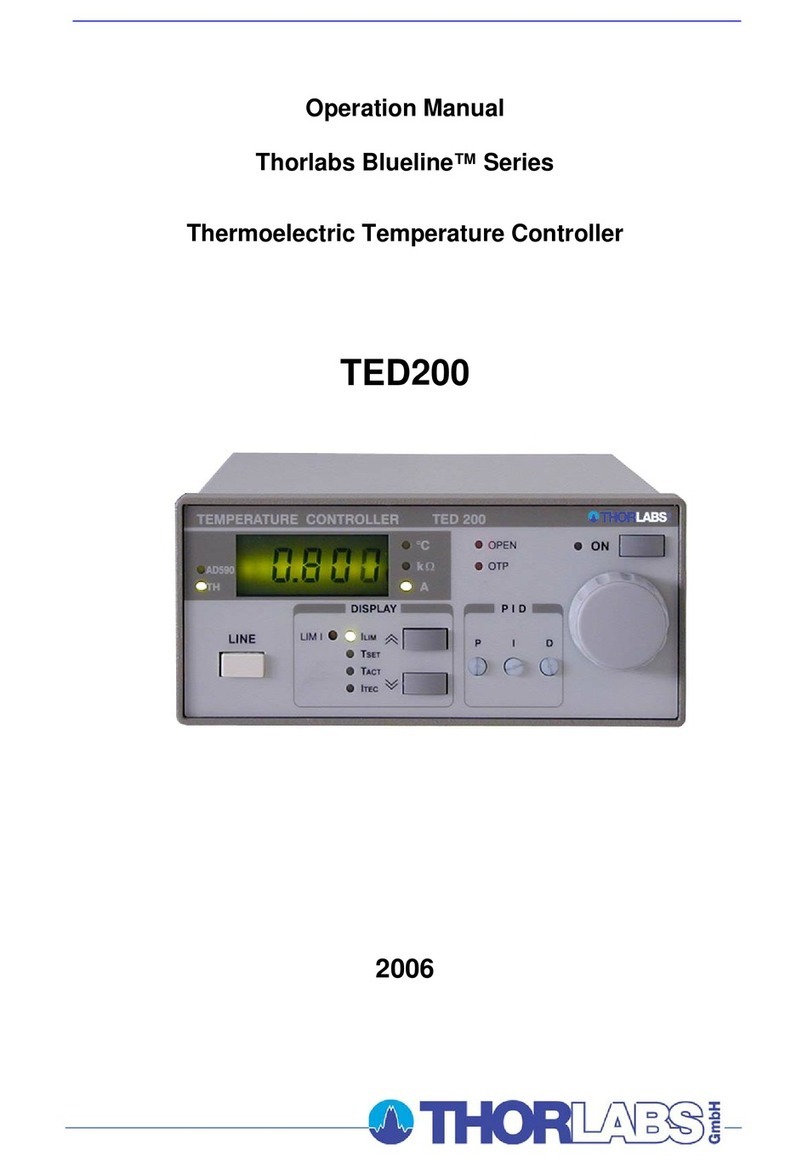

The TED200C is easy to operate via the operating elements on the front panel. Operating

parameters are shown on a5-digit LED display. UP-DOWN keys allow to select the parameter

to be displayed.

The P, Iand Dshares of the temperature control loop can be set independent of each other.

The TED200C operates with different temperature sensors -NTC thermistors and IC

temperature sensors are supported. With athermistor, the temperature is displayed in kW, with

atemperature sensor IC -in °C.

The output for the TEC current can be switched on or off via front panel key.

The temperature sensor and the TEC element are connected to a15-pin D-SUB jack at the

rear of the unit.

At the TE OUTPUT jack acontrol signal is available to drive an external LED to indicate TEC

ON mode when the TEC current is activated.

The set value of the temperature can be changed with aknob at the front panel or via an

analog input at the rear panel.

For monitoring purposes, an DC voltage proportional to the actual temperature is available at

the rear panel (CTL OUT).

The TED200C controller is cooled by an internal fan, which protects the unit against

overheating in case of high environmental temperatures. With free air circulation asafe

operation of the unit is guaranteed up to 40 °C ambient temperature.

Warning

Do not obstruct the air ventilation slots in the housing!

Note

In order to prevent damages to the laser diode, it is recommended to mount the laser into a

suitable Thorlabs laser diode mount (e.g., LM14S2, LDM21 or TCLDM9) and connect it to the

TED200C using the supplied Thorlabs CAB420-15 cable. This ensures the utmost protection of

the laser diode from damage by wrong connection.

In case of overheating, the output is switched off automatically in order to avoid damages. The

LED "OTP" (Overtemperature Protection) indicates the overtemperature. After atemperature

drop for about 10°C the LED "OTP" extinguishes and the output current can be switched on

again by pressing the key "ON".

If an error occurs (OTP or OPEN) the corresponding LED lights up and ashort warning beep is

heard.

The installed mains filter and the careful shielding of the transformer provide alow ripple at the

output.