Johnson Controls A19D User manual

Other Johnson Controls Temperature Controllers manuals

Johnson Controls

Johnson Controls PENN A70 Series User manual

Johnson Controls

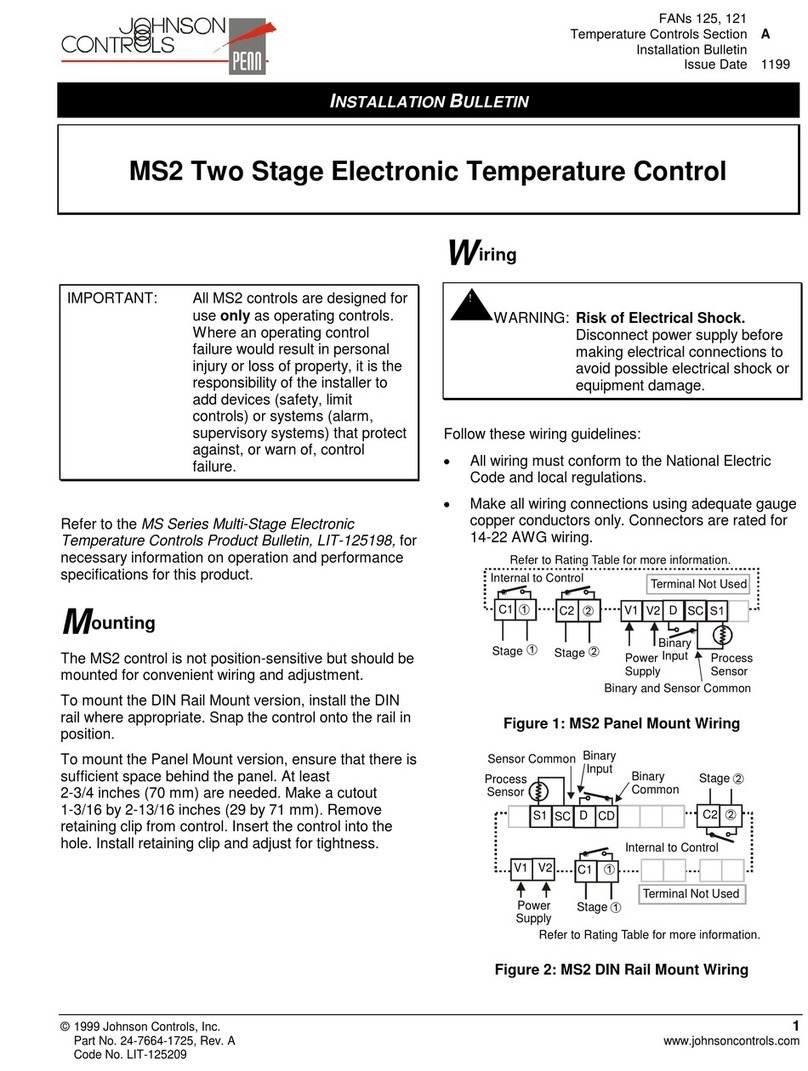

Johnson Controls MS2 Manual

Johnson Controls

Johnson Controls TE730 Series User manual

Johnson Controls

Johnson Controls A11A User manual

Johnson Controls

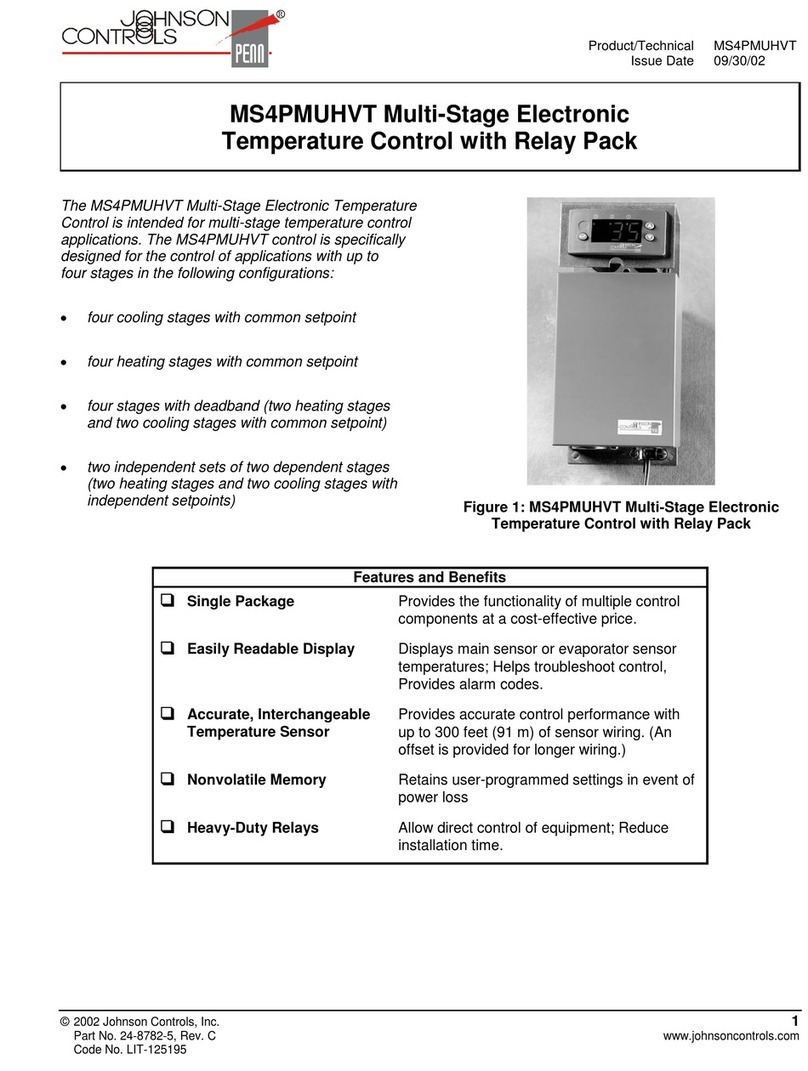

Johnson Controls MS4PMUHVT User manual

Johnson Controls

Johnson Controls WRZ-7860-0 User manual

Johnson Controls

Johnson Controls A419ABG-3C User manual

Johnson Controls

Johnson Controls A419 Series User manual

Johnson Controls

Johnson Controls FX-WRZ Series User manual

Johnson Controls

Johnson Controls T606MSP-4 User manual

Johnson Controls

Johnson Controls TM-2161 User manual

Johnson Controls

Johnson Controls TE-6800 Series User manual

Johnson Controls

Johnson Controls TE-63xS Series User manual

Johnson Controls

Johnson Controls System 350T A350P User manual

Johnson Controls

Johnson Controls TE-631xM User manual

Johnson Controls

Johnson Controls A419 Series Manual

Johnson Controls

Johnson Controls TE-6800 Series User manual

Johnson Controls

Johnson Controls A70 Series User manual

Johnson Controls

Johnson Controls A11D User manual

Johnson Controls

Johnson Controls W43A User manual

Popular Temperature Controllers manuals by other brands

P.W. KEY

P.W. KEY rt-208gt operating manual

BH Thermal

BH Thermal BriskONE owner's manual

West Control Solutions

West Control Solutions KS 45 Operation Notes

MCS

MCS RITC-15B Operator's manual

SMC Networks

SMC Networks Thermo-con INR-244-639 Operation manual

eltherm

eltherm Ex-TC It Series operating instructions

Omron

Omron C200H-TV Series Operation manual

industrie technik

industrie technik CA1 instructions

KRAL

KRAL EET 32 operating instructions

dixell

dixell XR420C Installing and operating instructions

Opt Lasers

Opt Lasers TEC-8A-24V-PID-HC operating manual

Vaillant

Vaillant VR 92/3 Operating and installation instructions