Derivative Time Slow answer or instability Decrease

Great oscillation Increase

Table 05 - Guidance for manual adjustment of the PID parameters

For further details on PID tuning, visit our web site:

www.novusautomation.com.

MAINTENANCE

PROBLEMS WITH THE CONTROLLER

Connection errors and inadequate programming are the most

common errors found during the controller operation. A final revision

may avoid loss of time and damages.

The controller displays some messages to help the user identify

problems.

MESSAGE DESCRIPTION OF THE PROBLEM

” until return to the Display PV screen.

j) Validate the calibration performed.

Note: When checking the controller calibration with a Pt100

simulator, pay attention to the simulator minimum excitation current

requirement, which may not be compatible with the 0.170 mA

excitation current provided by the controller.

IDENTIFICATION

N1030-PR Version with power supply 100~240 Vac

48~240 Vdc

N1030-PR-24V Version with power supply 12~24 Vdc / 24 Vac

SPECIFICATIONS

DIMENSIONS:............................................................48 x 48 x 35 mm

Approximate Weight:...............................................................60g

POWER SUPPLY: .........................100 to 240 Vac (±10 %), 50/60 Hz

...................................................................48 to 240 Vdc (±10 %)

Optional 24 V:................... 12 to 24 Vdc / 24 Vac (-10 % / +20 %)

Maximum consumption: ........................................................ 5 VA

ENVIRONMENTAL CONDITIONS:

Operation Temperature:............................................... 0 to 50 °C

Relative Humidity:...................................................80 % @ 30 °C

...............For temperatures above 30 °C, reduce 3 % for each °C

...... Internal use; Category of installation II, Degree of pollution 2;

altitude < 2000 meters

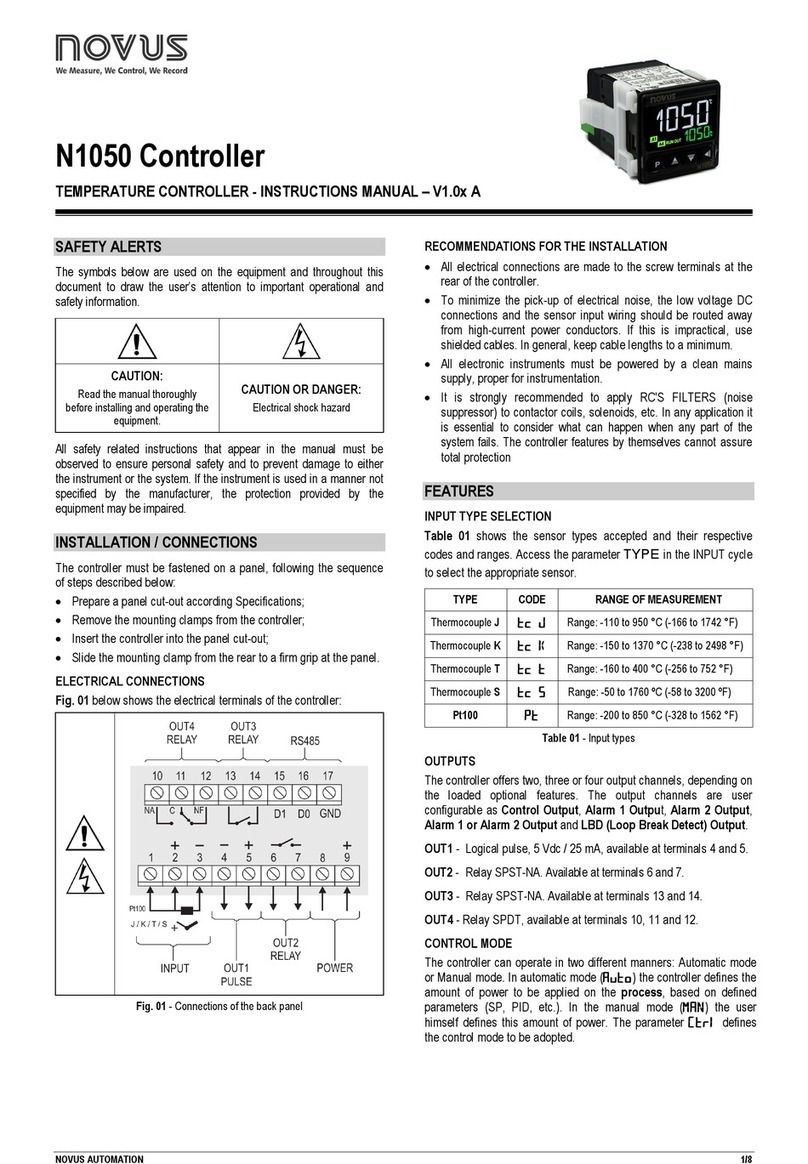

INPUT...... Thermocouples J; K; Tand Pt100 (according of Table 01)

Internal Resolution:......................................32767 levels (15 bits)

Resolution of Display:.........12000 levels (from -1999 up to 9999)

Rate of input reading:...........................................up 5 per second

Precision: Thermocouples J, K, T: 0.25 % of the span ±1 °C (*)

................................................................Pt100: 0.2 % of the span

Input Impedance:..................Pt100 and thermocouples: > 10 MΩ

Measurement of Pt100:.........................3-wire type, (α=0.00385)

With compensation for cable length, excitation current of 0.170

mA.

(*) The use of thermocouples requires a minimum time interval of 15

minutes for stabilization.

OUTPUTS: OUT1:................................Voltage pulse, 5 Vdc / 25 mA

OUT2:..................Relay SPST; 1,5 A / 240 Vac / 30 Vdc

FRONT PANEL:..........................IP65, Polycarbonate (PC) UL94 V-2

ENCLOSURE:..............................................IP30, ABS+PC UL94 V-0

ELECTROMAGNETIC COMPATIBILITY:...............EN 61326-1:1997

and EN 61326-1/A1:1998

EMISSION:............................................................CISPR11/EN55011

IMMUNITY:......................EN61000-4-2, EN61000-4-3, EN61000-4-4,

EN61000-4-5, EN61000-4-6, EN61000-4-8 and EN61000-4-11

SAFETY:..........................EN61010-1:1993 and EN61010-1/A2:1995

SPECIFIC CONNECTIONS FOR TYPE FORK TERMINALS;

PROGRAMABLE LEVEL OF PWM: from 0.5 up 100 seconds;

STARTS UP OPERATION: after 3 seconds connected to the power

CERTIFICATION:

WARRANTY

Warranty conditions are available on our web site

www.novusautomation.com/warranty.