Seite / page

5

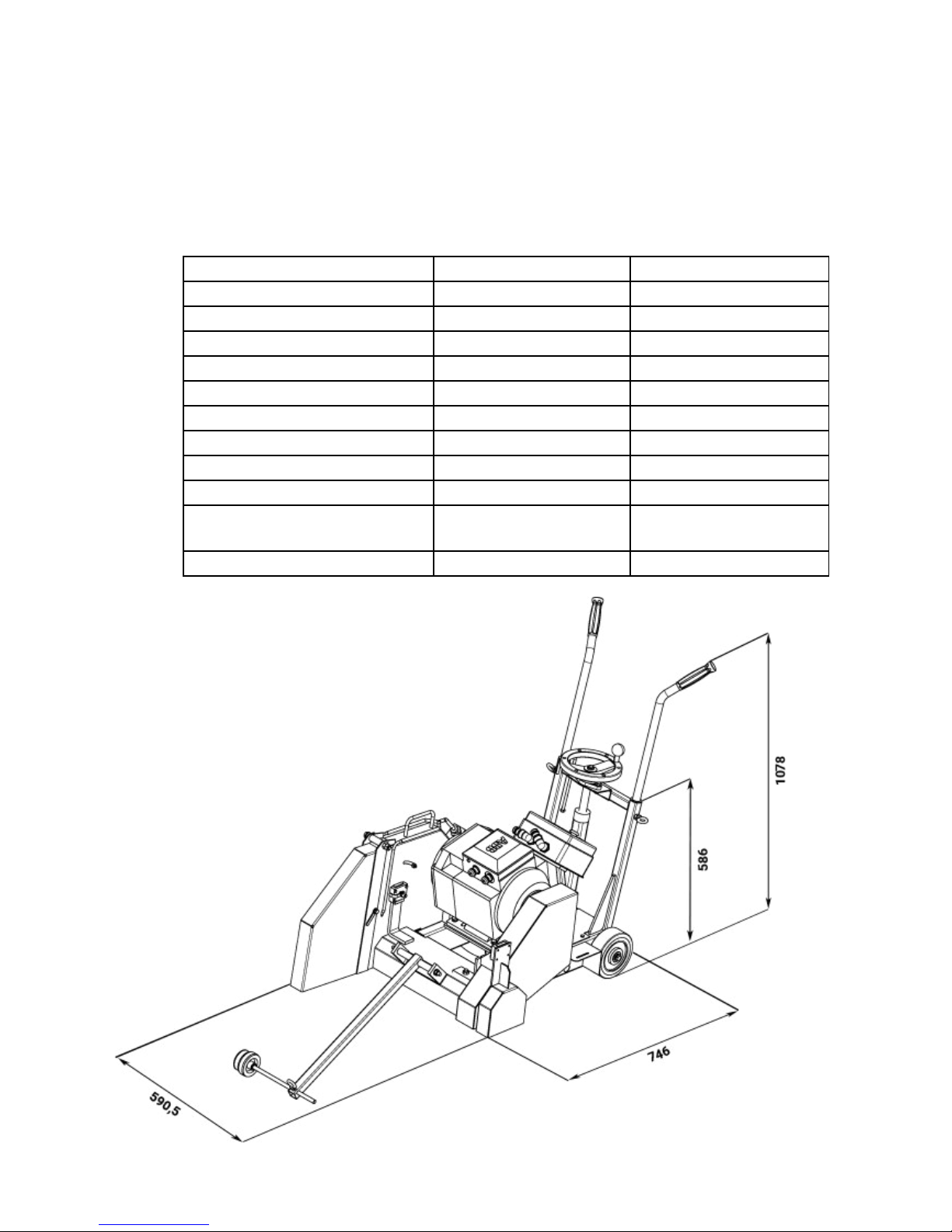

KDF 700E / 800E

Operating manual

the surroundings of the site. This is to avoid putting other persons

that notice has been given and received that you are about to com-

mence.

All maintenance work must only be carried out when the mains plug

is drawn.

Works on electrical facilities must only be executed by skilled wor-

kers or especially instructed persons under guidance and supervision

of a skilled worker corresponding to the electrotechnic rules.

using a cable avoidance tool for the detection of underground cabling

pipework.

accident prevention must be absolutely noted.

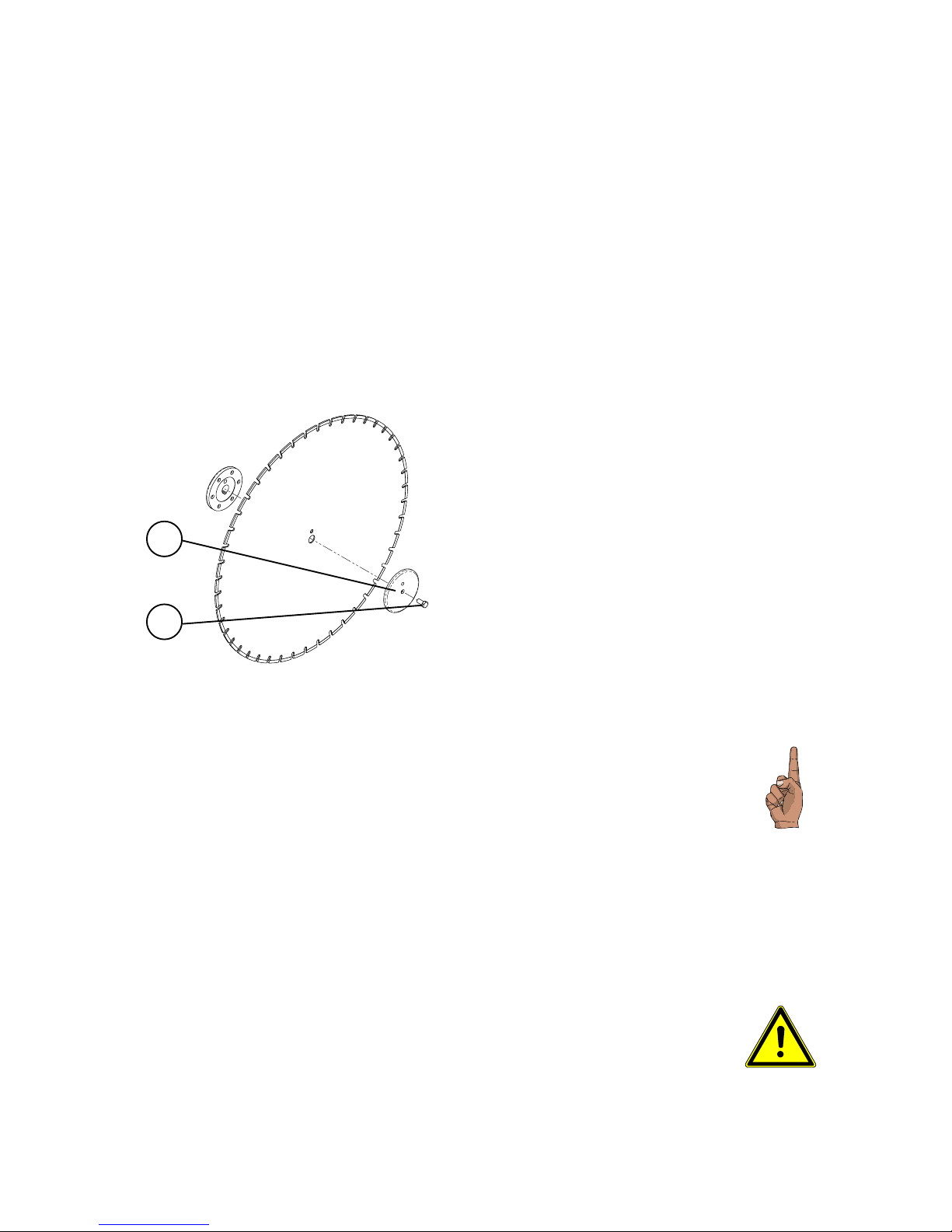

The blade guard should only be put on or removed from the saw

operating, make sure everything is in the right place and that you

have gone through all the safety procedures and devices.

When operating the saw one should always use ear protectors, glo-

ves, safety shoes and proper kind of clothing and goggles.

Before cleaning the machine with water, a vapour cleaner (high

pressure cleaning machine) or other cleaners, all apertures must be

covered for safety and to avoid water, vapour or cleaners entering it,

especially electric motors, switch boxes and electric plugs.

Covers and scotch tape must be removed after cleaning.

Floor saw