iii

TABLE OF CONTENTS

I. GENERALINFORMATION ........................................ 1

1.1 Specifications ............................................. 2

1.2 Options .................................................. 2

II. INSTALLATION ................................................. 3

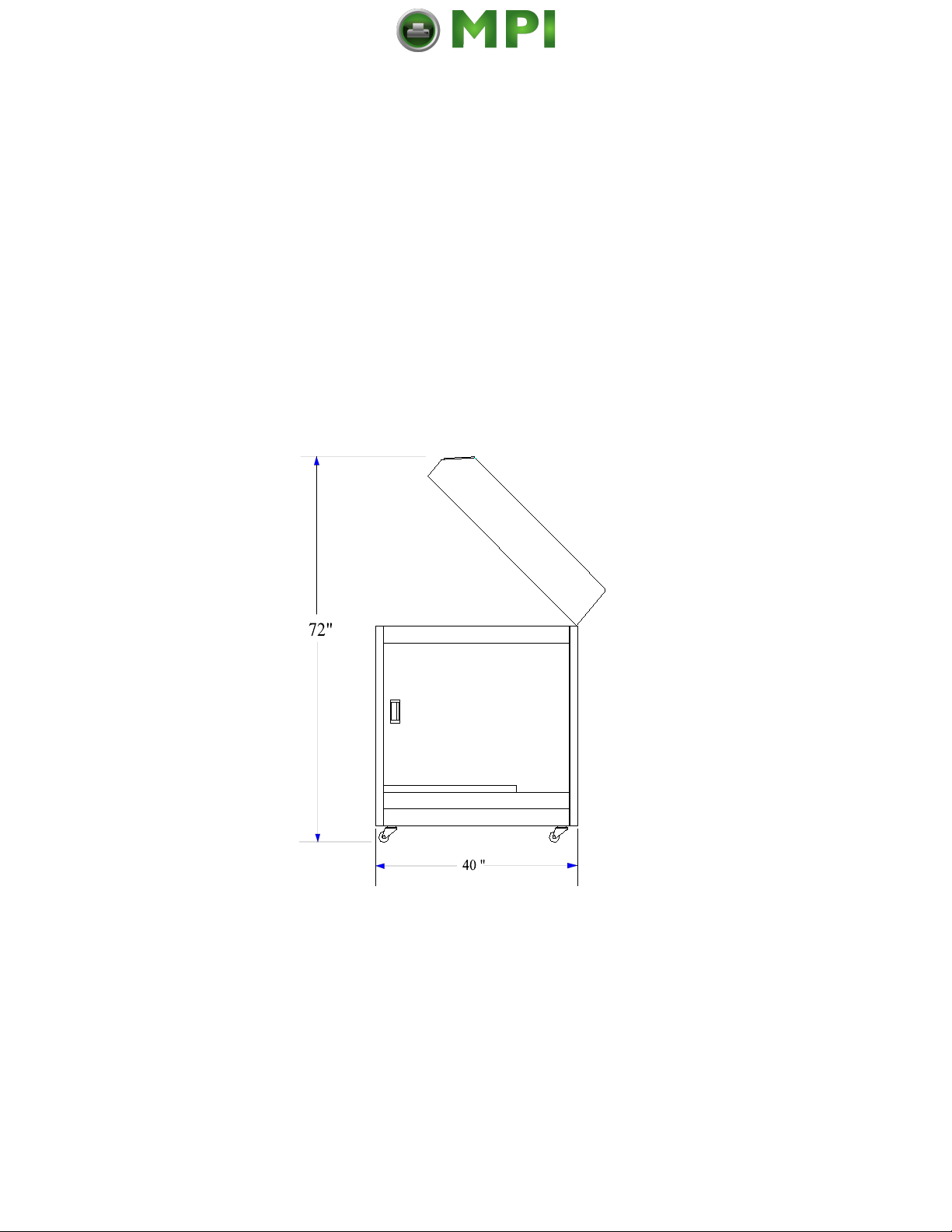

2.1 SpaceRequirements........................................ 3

2.2 Unpacking ................................................ 5

2.3 Configuration.............................................. 8

2.4 InterfaceCableRequirements ................................ 8

III. THEORYOFOPERATION ....................................... 10

3.1 SystemBlockDiagram ..................................... 10

3.2 Electronics............................................... 10

3.2.1 AC/DCPowerDistribution ................................... 10

3.2.2 DCDistributionBoard ...................................... 10

3.2.3 BusBoard ............................................... 11

3.2.4 MicroprocessorBoard ...................................... 11

3.2.4.1 MicroprocessorDesign .................................. 11

3.2.4.2 InterfaceData ......................................... 11

3.2.4.3 PaperfeedSystem ...................................... 11

3.2.4.4 Interlocks ............................................. 11

3.2.4.5 DrapeSensor.......................................... 12

3.2.4.6 RibbonDrive .......................................... 12

3.2.4.7 AnalogDesign ......................................... 12

3.2.4.8 HammerProtectionCircuit................................ 13

3.2.5 HammerDriverBoard ...................................... 13

3.2.5.1 HammerCircuitDesign .................................. 13

3.2.5.2 HammerTestRoutine ................................... 13

3.2.5.3 HammerFlightTimeRoutine .............................. 13

3.2.6 Operator'sPanel .......................................... 14

3.2.7 PaperPullerBoard ........................................ 14

3.3 Mechanics ............................................... 14

3.3.1 PaperfeedSystem......................................... 14

3.3.2 RibbonSystem ........................................... 14

3.3.3 PaperPuller ............................................. 14

3.4 CharacterandControlCodes ................................ 15

3.4.1 CharacterSetCodes....................................... 15

3.4.2 FormatControlCodes...................................... 15

IV. REPLACEMENTPROCEDURES .................................. 17

4.0 TOOLSREQUIRED ....................................... 17

4.1 HammerModule .......................................... 18

4.2 Hammerbackstopscrew.................................... 19

4.3 Drummotor .............................................. 20

4.4 PaperFeedmotor ......................................... 21

4.5 Ribbonincrementmotor .................................... 22

4.6 Ribbontakeupmotor....................................... 23

4.7 Paperpullermotor......................................... 24

4.8 DrumBelt ............................................... 25

4.9 Paperfeedbelts .......................................... 26

4.10 Ribbonincrementbelt ...................................... 27

Mantenimiento Periféricos Informáticos SL C/Canteras, 15 28860 Paracuellos de Jarama Tel: 00 34 917481604 WEB: https://mpi.com.es