CONTENTS

EC DECLARATION OF CONFORMITY

1INTRODUCTION ..................................................................................................1

1.1GENERAL INFORMATION............................................................................................... 2

1.1.1Storing the manual..................................................................................................... 2

1.1.2Manual contents ........................................................................................................ 2

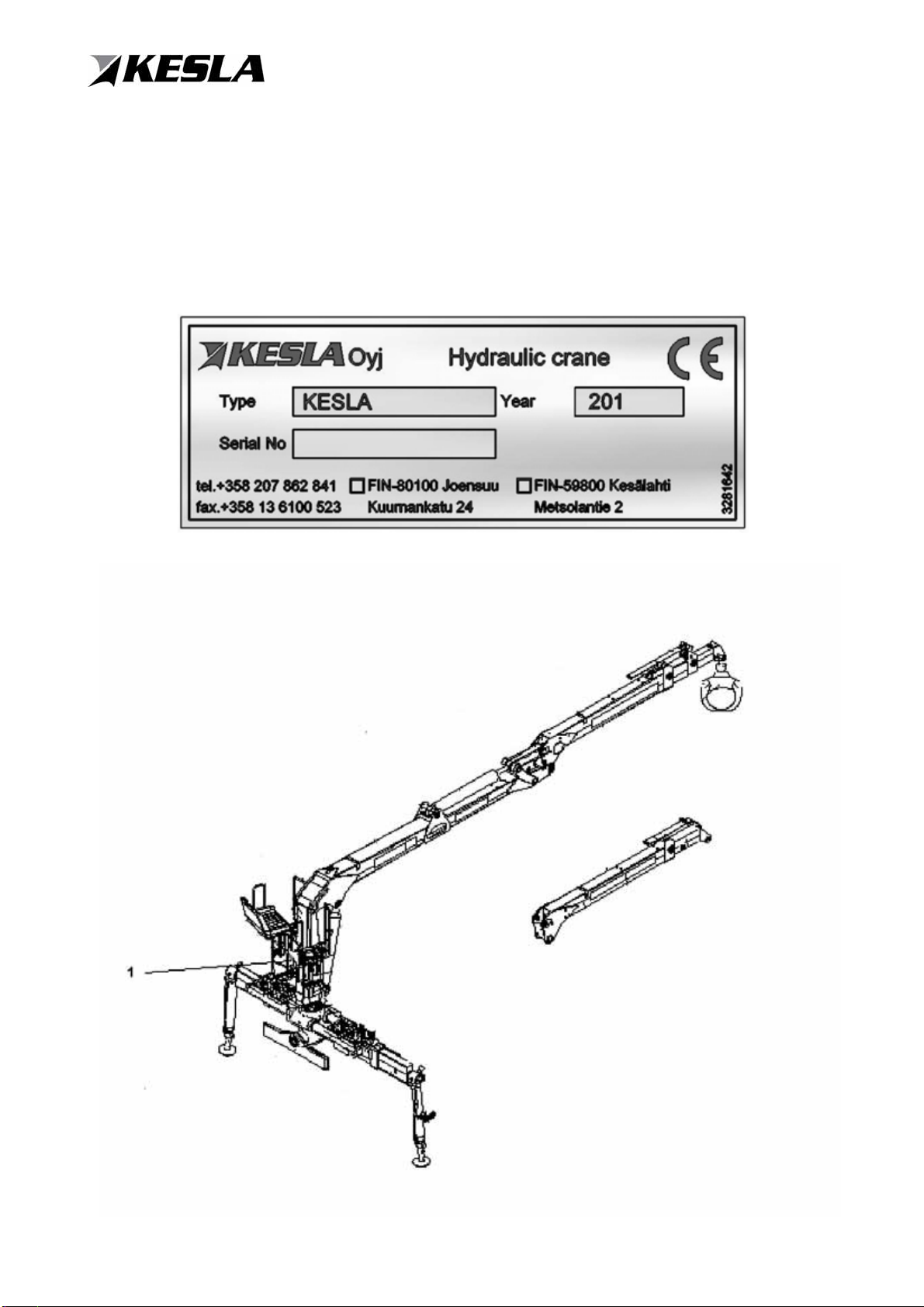

1.2MACHINE PLATE ............................................................................................................. 3

1.3PURPOSE OF THE CRANE............................................................................................. 4

1.4RECOMMENDED OPERATING CONDITIONS................................................................ 4

1.5PROHIBITED USAGE AND CONDITIONS OF USE........................................................ 4

1.6GENERAL WARRANTY TERMS FOR KESLA PRODUCTS............................................ 5

1.7THE INFORMATION AND WARNING SYMBOLS IN THE MANUAL............................... 7

1.7.1Warning symbols....................................................................................................... 7

1.8CONTACT INFORMATION............................................................................................... 7

2SAFETY INSTRUCTIONS....................................................................................8

2.1GENERAL SAFETY INFORMATION................................................................................ 8

2.2THE BIGGEST SECURITY RISKS WHEN OPERATING AND MAINTAINING THE

CRANE............................................................................................................................. 9

2.3SAFETY INSTRUCTIONS .............................................................................................. 10

2.3.1Danger zones during use......................................................................................... 11

2.3.2Safety devices ......................................................................................................... 12

2.3.3Emergency stops..................................................................................................... 13

2.3.4Priorities and dimension drawings........................................................................... 13

2.3.5Caution and warning signs on the crane ................................................................. 14

2.4HYDRAULIC SYSTEM.................................................................................................... 19

2.5SAFETY INSTRUCTIONS FOR HANDLING CHEMICALS ............................................ 20

2.6WELDING THE CRANE.................................................................................................. 21

2.7INSTALLING ACCESSORIES AND MODIFYING THE DEVICE STRUCTURE............. 21

2.8SAFETY PRECAUTIONS ON THE ROAD ..................................................................... 22

2.9USER’S MANUAL KESLA CE -EQUIPMENT................................................................. 23

3ABOUT THE CRANE .........................................................................................26

3.1CRANE'S MAIN COMPONENTS.................................................................................... 26

3.2CRANE OPERATION...................................................................................................... 27

3.3CRANE EQUIPMENT OPTIONS.................................................................................... 27

3.3.1Basic crane models ................................................................................................. 27

3.3.2Crane accessories................................................................................................... 28

4COMMISSIONING..............................................................................................29

4.1SAFETY INSTRUCTIONS FOR THE CRANE’S COMMISSIONING.............................. 29

4.2PREPARATIONS FOR CRANE COMMISSIONING....................................................... 29

4.3CRANE MOUNTING....................................................................................................... 30

4.3.1Installation to a movable stand behind a truck......................................................... 31

4.3.2Installing the crane behind the cabin....................................................................... 32

4.3.3Installation of the rotator and its hoses in Keslink:................................................... 33

4.3.4Hose connections.................................................................................................... 34

4.4INSTALLER..................................................................................................................... 35

4.4.1Safety instructions ................................................................................................... 35

4.5INSPECTIONS................................................................................................................ 35

4.5.1Commissioning inspection....................................................................................... 35

4.5.2Warranty service...................................................................................................... 35

4.5.3Periodic inspections................................................................................................. 36

4.5.4Thorough periodic inspection................................................................................... 36

4.5.5The crane's daily inspection..................................................................................... 36

4.6INSTRUCTIONS ON HOW TO CALCULATE THE CRANE'S STANDING STABILITY.. 37

4.7INSTRUCTIONS ON HOW TO DETERMINE EXPERIMENTALLY THE CRANE'S

STANDING STABILITY .................................................................................................. 38

4.7.1Safety instructions ................................................................................................... 38

4.7.2Test conditions......................................................................................................... 38