4

2.0 Conversion Guide

Often times KEP is asked to give the cable pin out for SMIC cables that have converter boxes in the middle. It

becomes impractical for the user to make the cable electronics but some insist on trying. Usually a

manufacturers programming cable to connect a PC RS232 port to the Controller is the same configuration as

our SMIC cable. The SMIC cable is usually less expensive than the manufacturers in these instances. However

the SMIC cannot be used with a PC. This is because the SMIC draws it power from the ZOID or MMI product

using it. Below is a list of cables with conversion type to use as a reference.

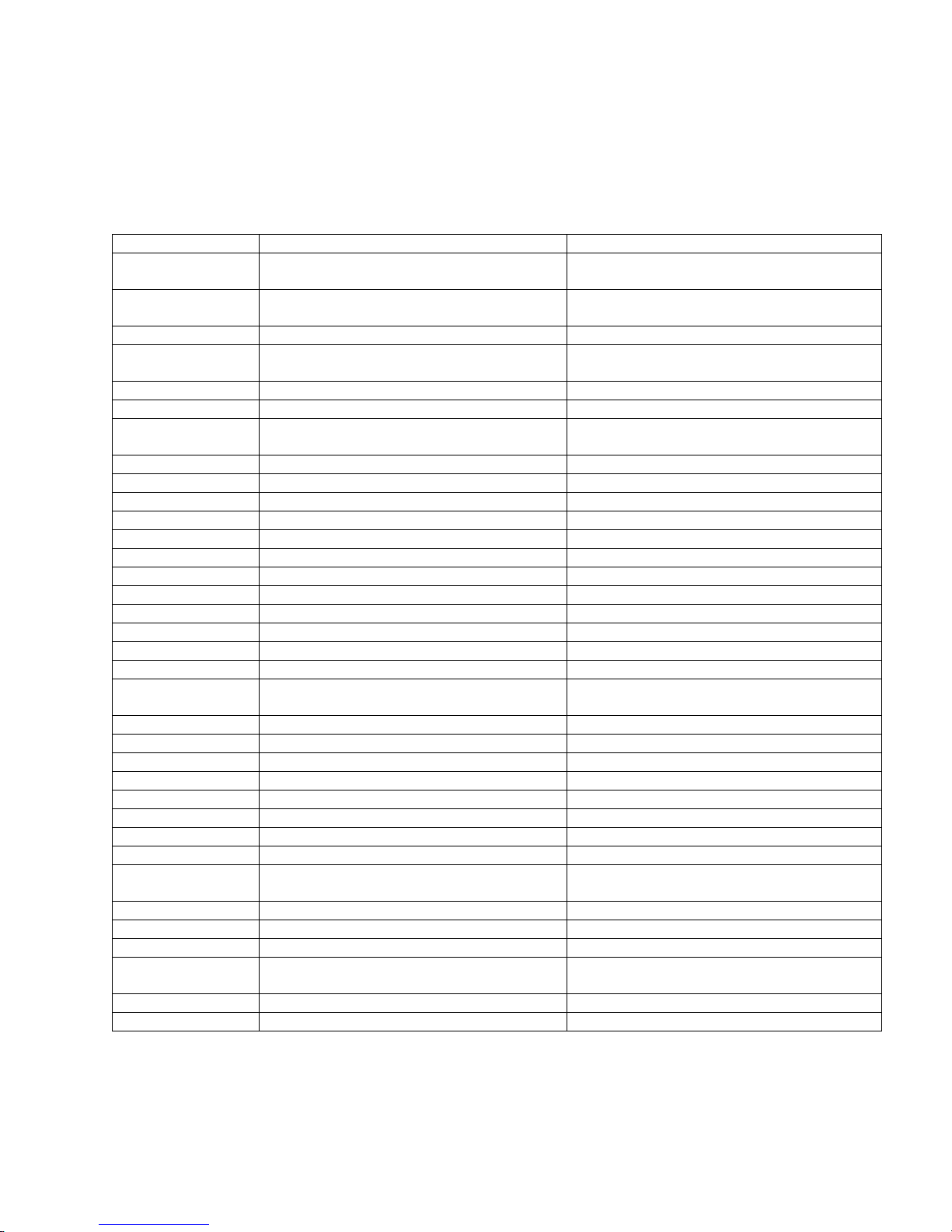

Cable PLC Compatibility Conversion type

SMICAB500

SMICABAIC All Allen Bradley SLC500 types with

DH485 port RS232 !2 wire RS485

SMIC7AB500

SMIC15AB500 All Allen Bradley SLC500 types with

DH485 port 2 wire RS485 No conversion

SMICABMICRO Allen Bradley MicroLogix only RS232 No conversion

SMICABDF1 Allen Bradley SLC5/03, 5/04 with DF1

port RS232 No conversion

SMICFUJI All Fuji Flex Series RS232 !4 wire RS485

SMICGE90 All GE 90 Series SNP Port RS232 !4 wire RS422

SMIC7GE90

SMIC15GE90 All GE 90 Series SNP-X Port 4 wire RS422 No conversion

SMICIDECM1 IDEC Micro 1 Series only RS232 !5V TTL Serial

SMICIDECM3 IDEC Micro 3 Series only RS232 !2 wire RS485

SMICIDECM3C IDEC Micro 3 Series with RS232 port RS232 No conversion

SMICK205 Koyo DL230, 240, 250 RS232 No conversion

SMICK305 Koyo 340, Siemens 335, 337 RS232 No conversion

SMICK405 Koyo 440, Siemens 425, 435 RS232 No conversion

SMICKEY All Keyence KV series RS232 No conversion

SMICMOD Controllers with DB9 MODBUS RTU ports RS232 No conversion

SMICMODMICRO Modicon Micro 984 RS232 No conversion

300_A1S Mitsubishi A Series RS232 !4 wire RS422

500_AnS Mitsubishi A Series RS232 !4 wire RS422

SMICMITFX Mitsubishi FX Series RS232 !4 wire RS485

SMIC7MITFX

SMIC15MITFX Mitsubishi FX Series RS232 !4 wire RS485

SMICMITFXO Mitsubishi FXo and FXn only RS232 !4 wire RS485

SMIC15MITFXO Mitsubishi FXo and FXn only RS232 !4 wire RS485

SMICOMCH9 Omron CH Series RS232 No conversion

SMICOMCK25 Omron C series (Host Link Modules) RS232 No conversion

SMICOMCQM Omron CQM1 Series RS232 No conversion

SMICSIS5 Siemens S5 Series RS232 !Opto-isolated current loop serial

SMIC7S IS7 2 wire RS485 No conversion

SMICSIS7 Siemens S7 200 Series only RS232 !2 wire RS485

SMICTSBEX Toshiba EX and M Series, program port

only RS232 !Current loop serial

SMICTSB485 Toshiba EX and M Series, Link port only RS232 !4 wire RS485

SMICTSBT1 Toshiba T Series T1 only RS232 No conversion

SMICTSBT2 Toshiba T Series T2, T3 RS232 No conversion

SMICTSX07 Telemecanique TSX 07 (nano) and 37

Series RS232 !2 wire RS485

SMICTSX17 Telemecanique TSX 17 Series RS232 !2 wire RS485

SMICTSX47 Telemecanique TSX 47-40, 47-20 RS232 !Opto-isolated current loop serial