•SAFETY INSTRUCTIONS

The instructions in this user’s guide include critical information for safe use.

When you do not keep the instructions, you may cause death, serious injury and

property damage.

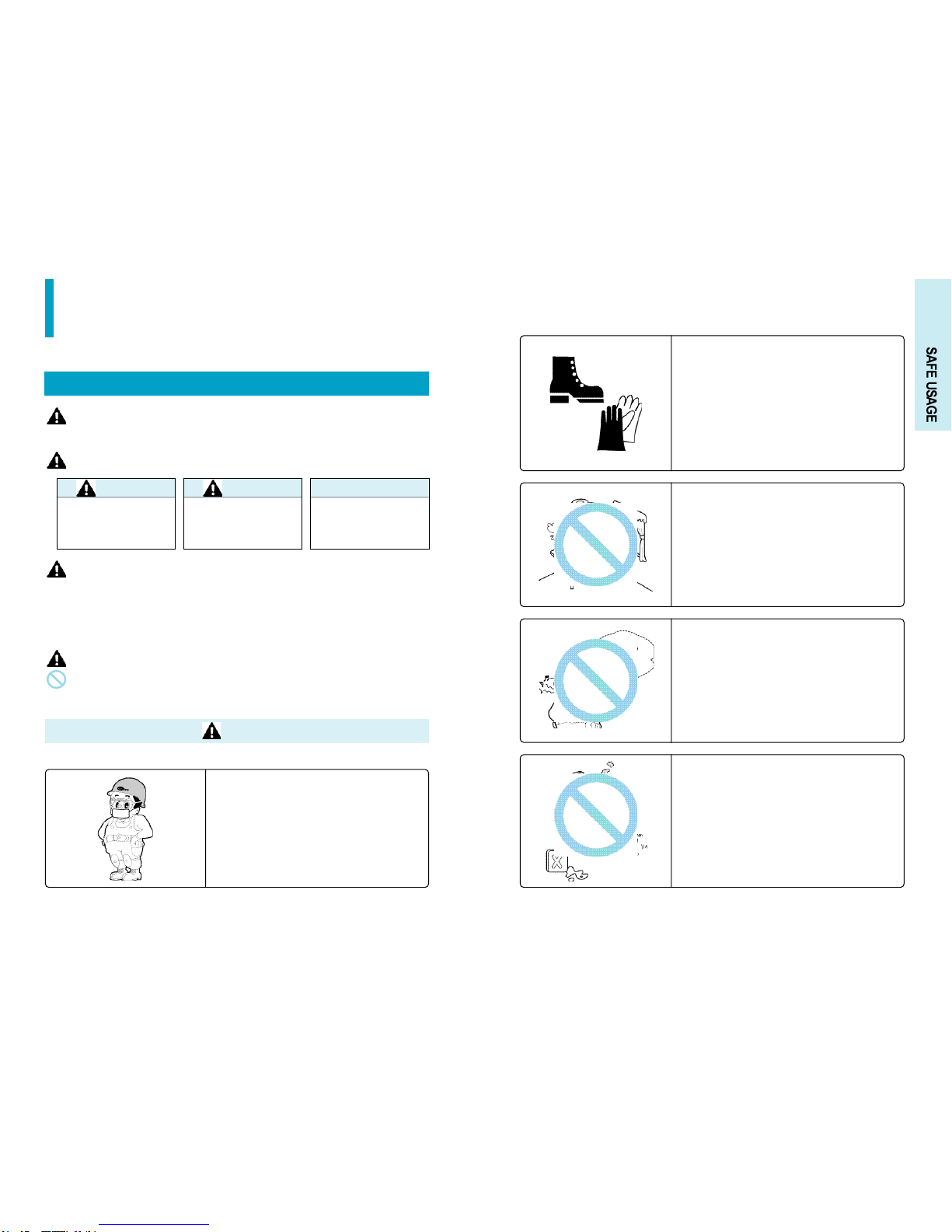

For safe usage, the notations are divided into“Warning”and“Caution”depending on the

level of danger involved. Their meanings are as follows:

In order to prevent accidents that can happen easily while using or handling the power mist & duster, and also

for safe work, the Safety Instructions consist of Clothing, Environment, Fire hazards, Pre-operation stages,

Operational stages and Postoperation stages. These warnings and cautionary instructions for safety cannot

cover all possible situations or conditions that can happen. Therefore, scrupulous cares are needed when

operating or storing the product. Please read completely and understand. And be careful so that accident does

not occur.

In the event the instruction

is not followed, it is

possible that serious injury

or death may occur highly.

In the event the instruction

is not followed, it is

possible that serious injury

or death may occur.

In the event the instruction is not

followed, it is possible that troubles,

which can disable or degrade the

product performance, may occur.

CautionWarning Caution

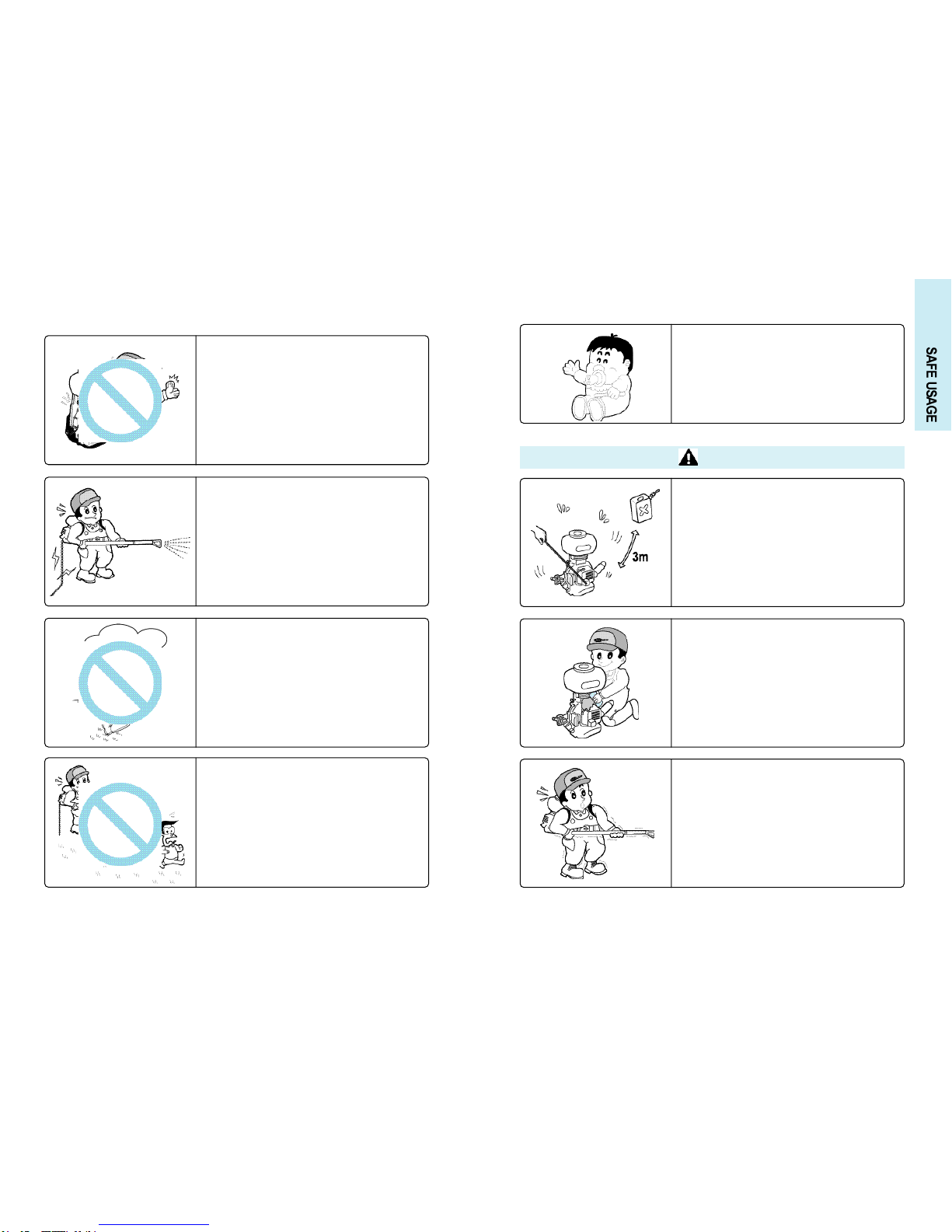

When working, wear the following protective

gears.

■To protect head, wear safety hat.

■To protect eyes, wear safety glasses.

■To protect ears, wear earmuffs.

■Wear knee protectors.

If protective gears were not worn, flying objects such as

rocks can cause injuries.

Warning

1. SAFE USAGE

※

Illustrative signs used on the product and in the handling instructions are as follows:

This sign means“Care is needed”because there are possibilities that danger may occur under certain conditions.

This sign means“Prohibited”because there are possibilities that danger may occur under certain conditions.

4 5

Wear clothing that is suitable for work.

■Wear slip resistant safety shoes.

■Wear gloves when working.

■Tie long hairs above shoulders.

■Do not wear hanging down clothes, neckties, scarves,

or ribbons.

Working with unsuitable clothing can become a cause of

accident by slipping, getting burned, or getting caught in

the machine while working.

Do not use the tool in indoors or where ventilation is

poor.

Do not use when you are unable to operate the

product normally due to alcohol, drug or

anything else.

■It can causes a safety accident.

Be careful to the flammable.

■It can causes serious injury.