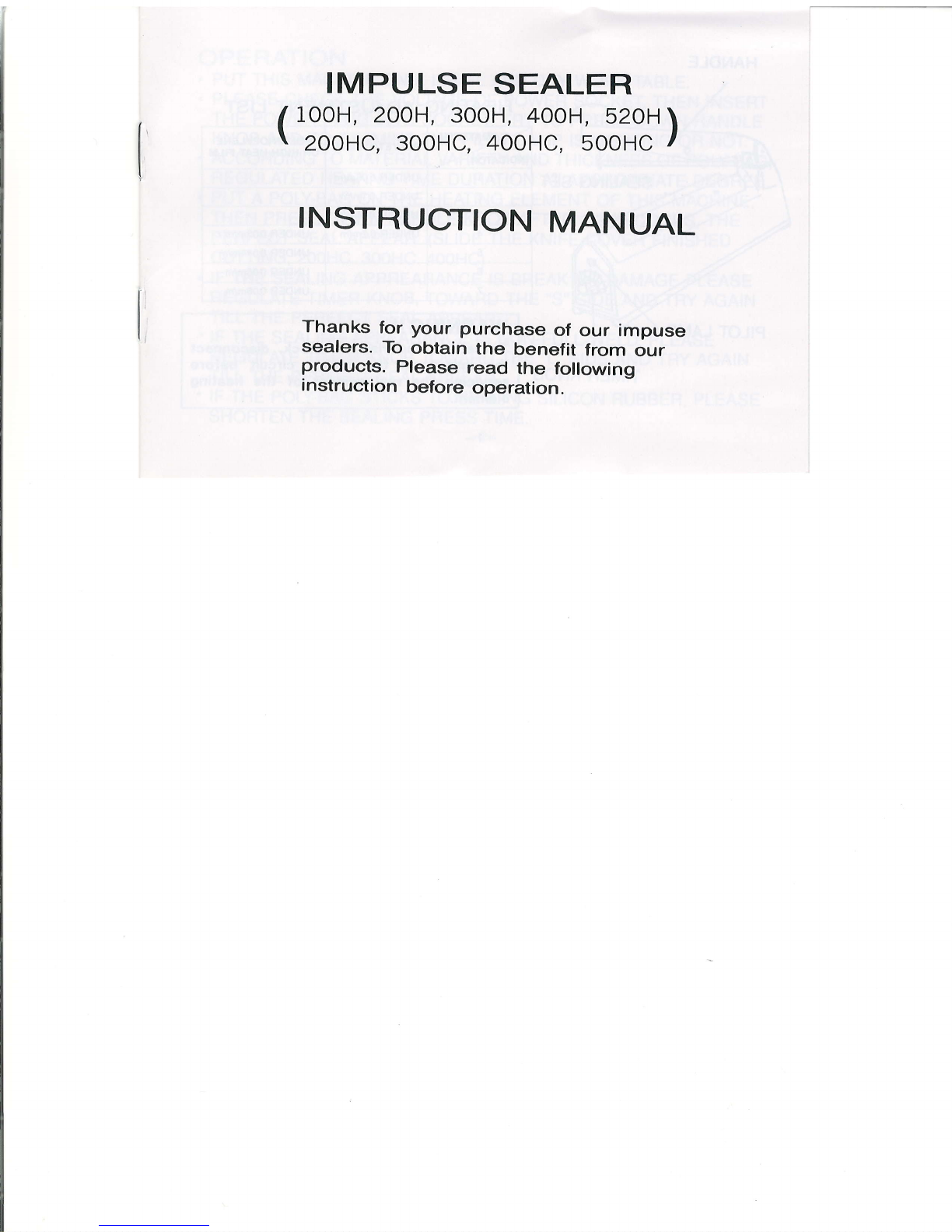

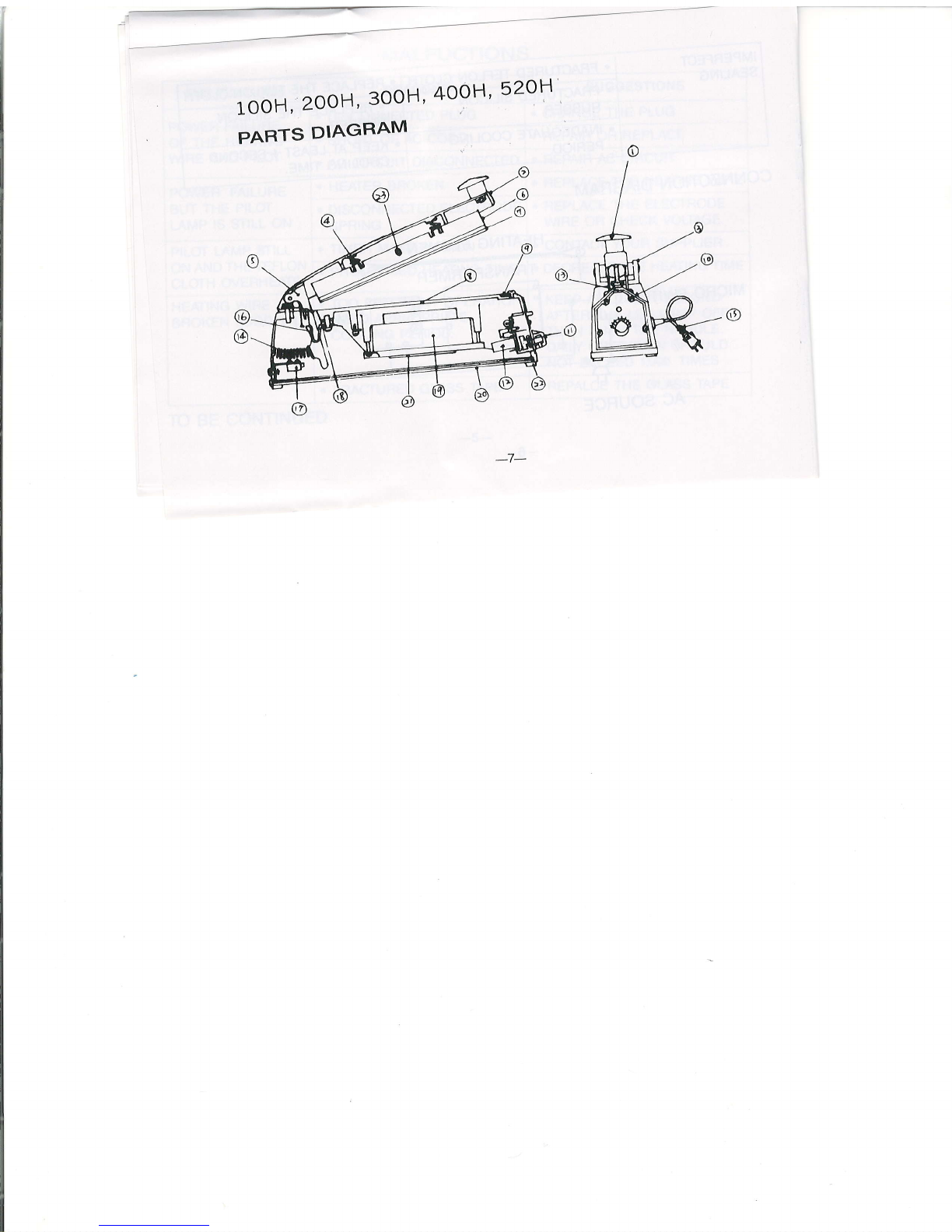

HANDLE

\

TIMER

KNOB

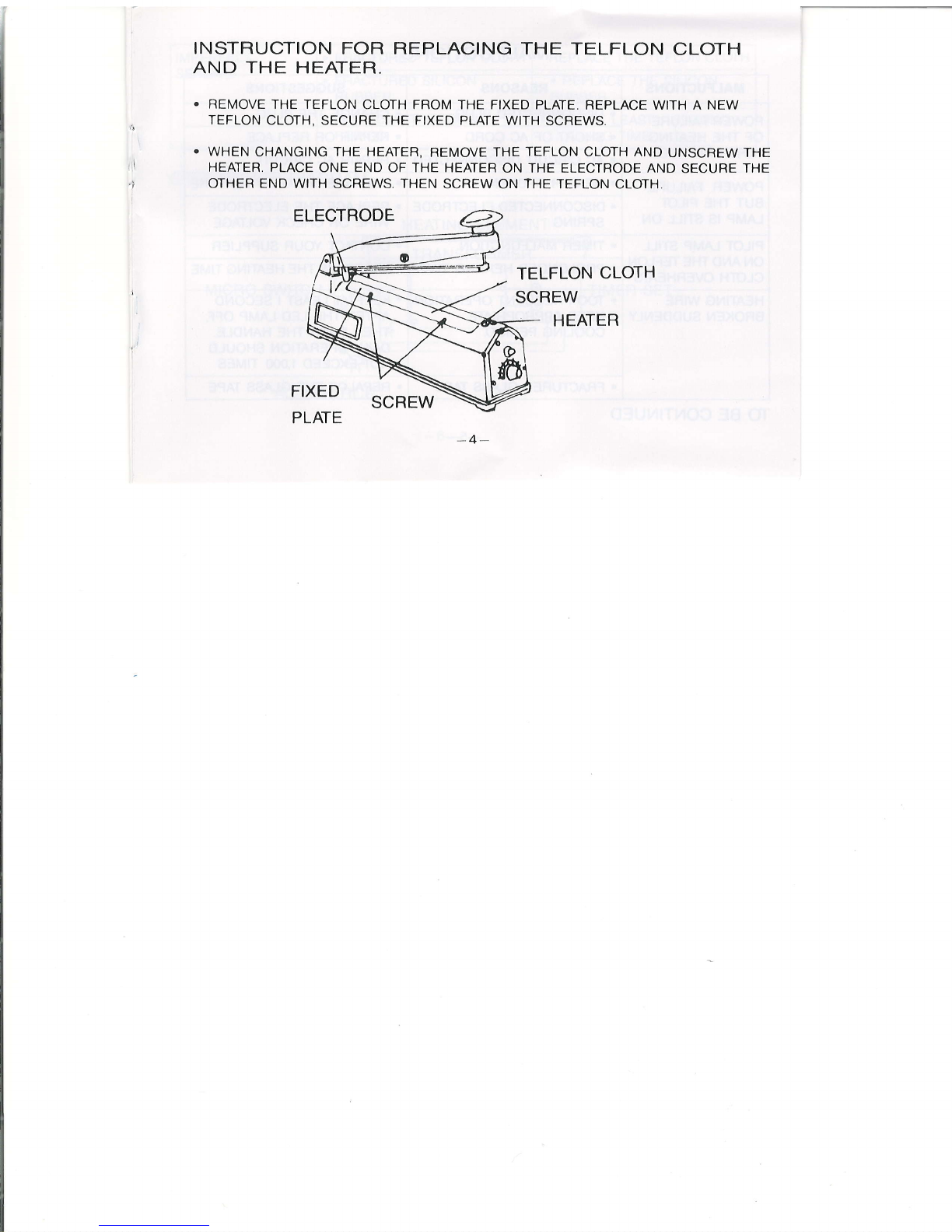

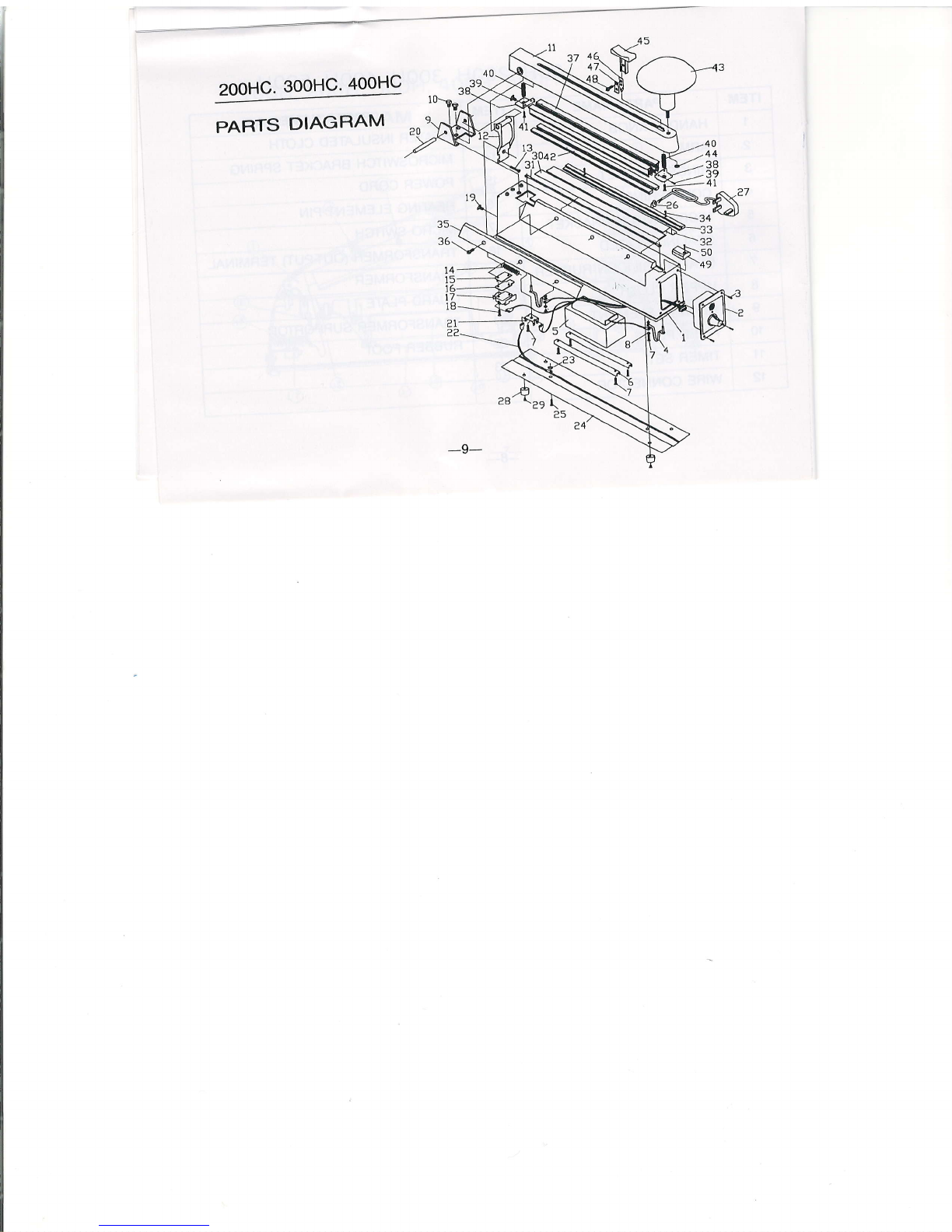

WARNING!!

To reduce the risk of shock, disconnect

the unit from the supply circuit before

servicing the replacement of the heating

element.

-1-

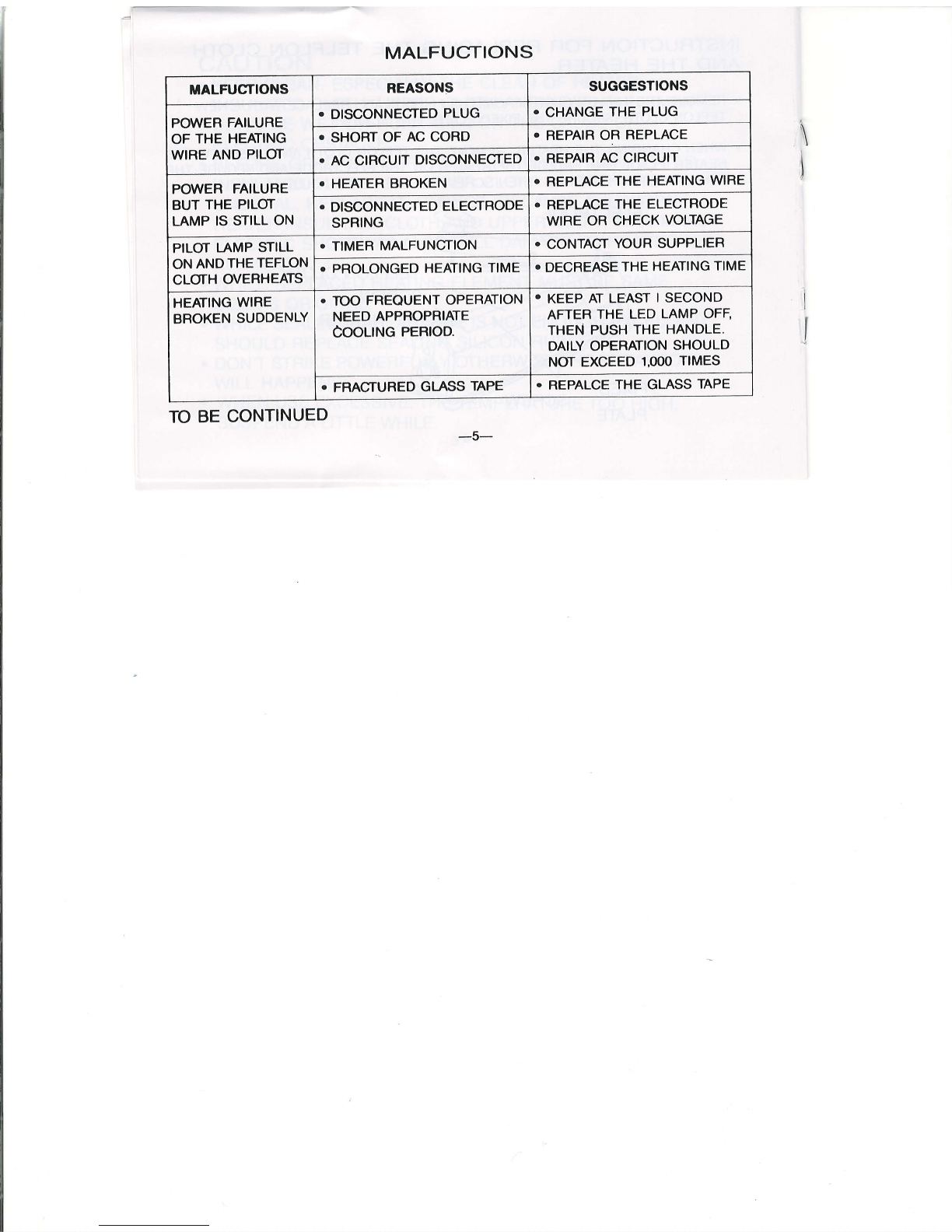

HEATINGADJUSTMENT LIST

{enrlt-

trOlClfOR---'- POLYETHYLENE POLYPROPYLENE

OR HIGH-HEATFILiI

UNDER006m/m

2UNDER0.1m/m

3UNDER0.14m/m

4UNDER0.2mlm UNDER

0.03m/m

qUNDER

0.044m/m

6UNDER

0.06m/m

7UNDER

OOBm/m