1

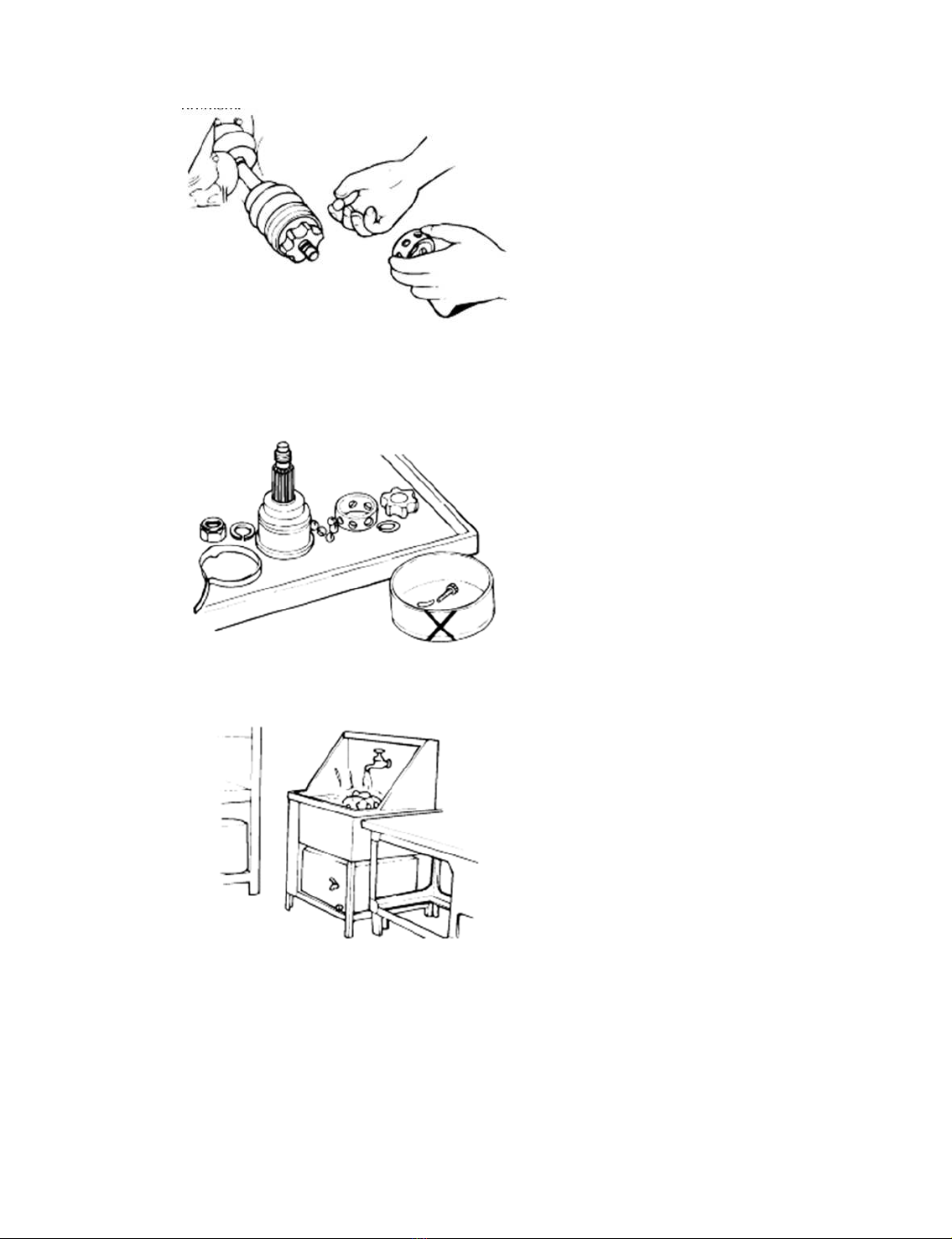

GENERAL INFORMATION

GENERAL

EATC0100

HOW TO USE THIS MANUAL

This manual is divided into 21 sections. The first page of each section is marked with a black tab at the edge of the

page. You can quickly find the first page of each section without looking through the whole table of contents.

Each section includes the essential removal, installation, adjustment and maintenance procedures for servicing all

body styles. This information is correct at the time of publication.

An INDEX is provided on the first page of each section to guide you to the appropriate item.

TROUBLESHOOTING tables are included for each system to help you diagnose the system problem and find the

cause. The repair for each possible cause is referred to in the remedy column to lead you to the solution quickly.

DEFINITION OF TERMS

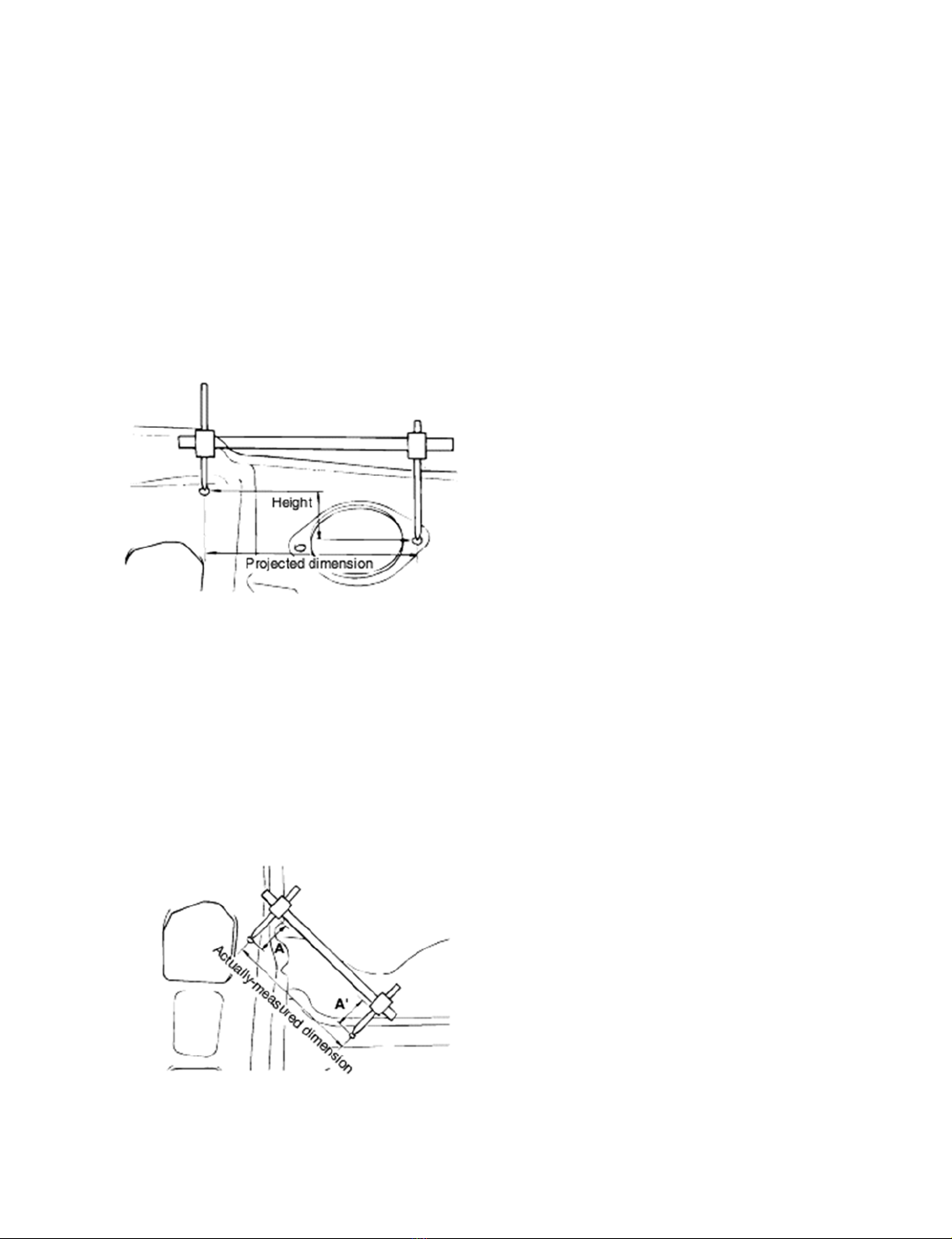

Standard Value (Service standard)

Indicates the value used when a part or assembled item should be inspected, or the value to which a part or

assembled item should be adjusted after reinstallation. It is given by a tolerance.

Service Limit

Indicates the maximum or minimum value that a part or assembled item must meet when inspected. It is a value

established beyond the standard value.

NOTE, WARNING , CAUTION, ABBREVIATION

NOTE

Information needed in reference to a repair service.

CAUTION

Information about an activit

that could cause dama

e to the vehicle.

WARNING

Information about an activity that could cause injury or damage to the driver, occupants or

repairman.

ABBREVIATIONS

SOHC : Single Over Head Camshaft

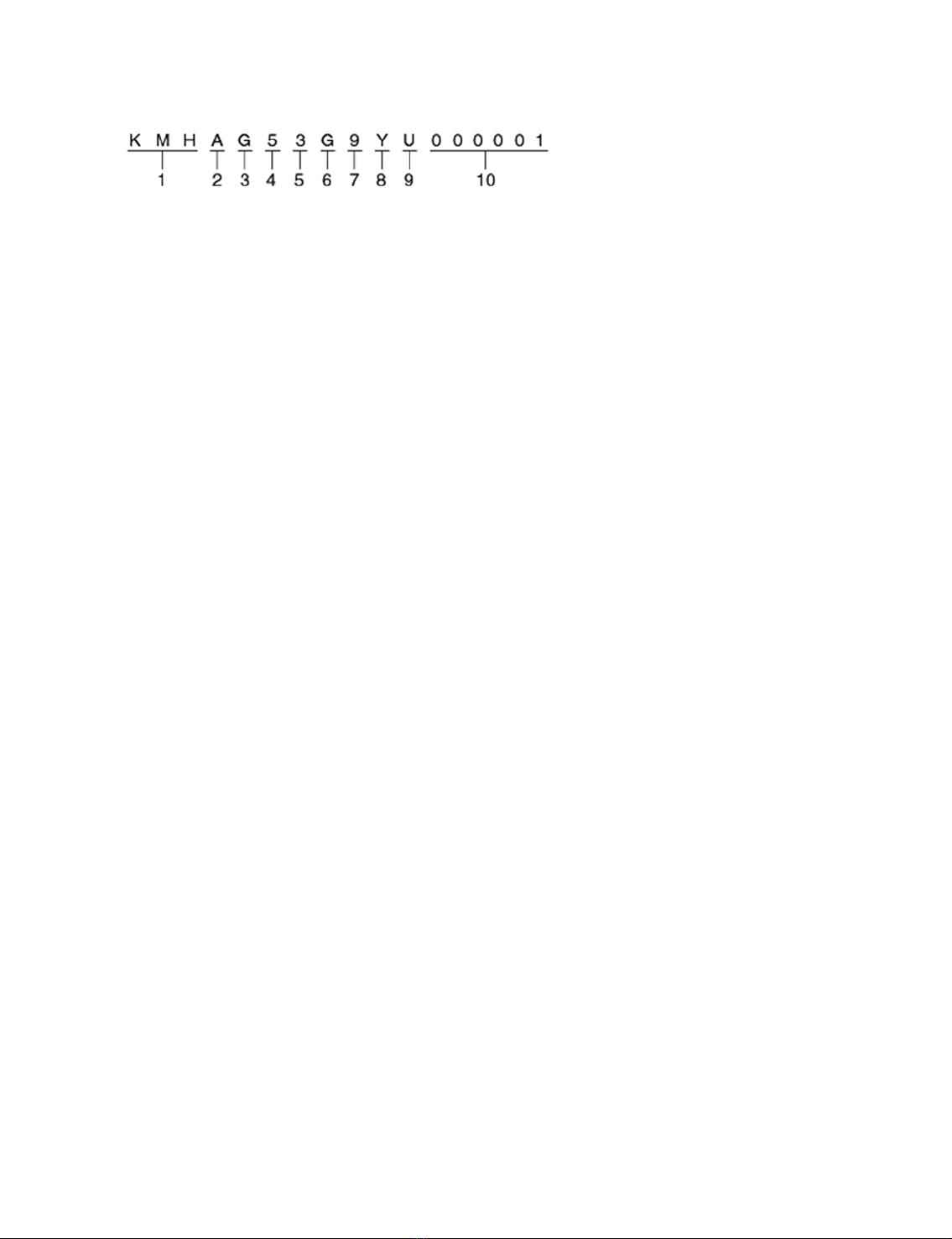

VEHICLE IDENTIFICATION NUMBER LOCATION

The vehicle identification number (VIN) is located on the top of the fire wall.