Page Hobbyfuser 3 Manual

10

Element Replacement.

In the event of an element failure replacement is easy done.

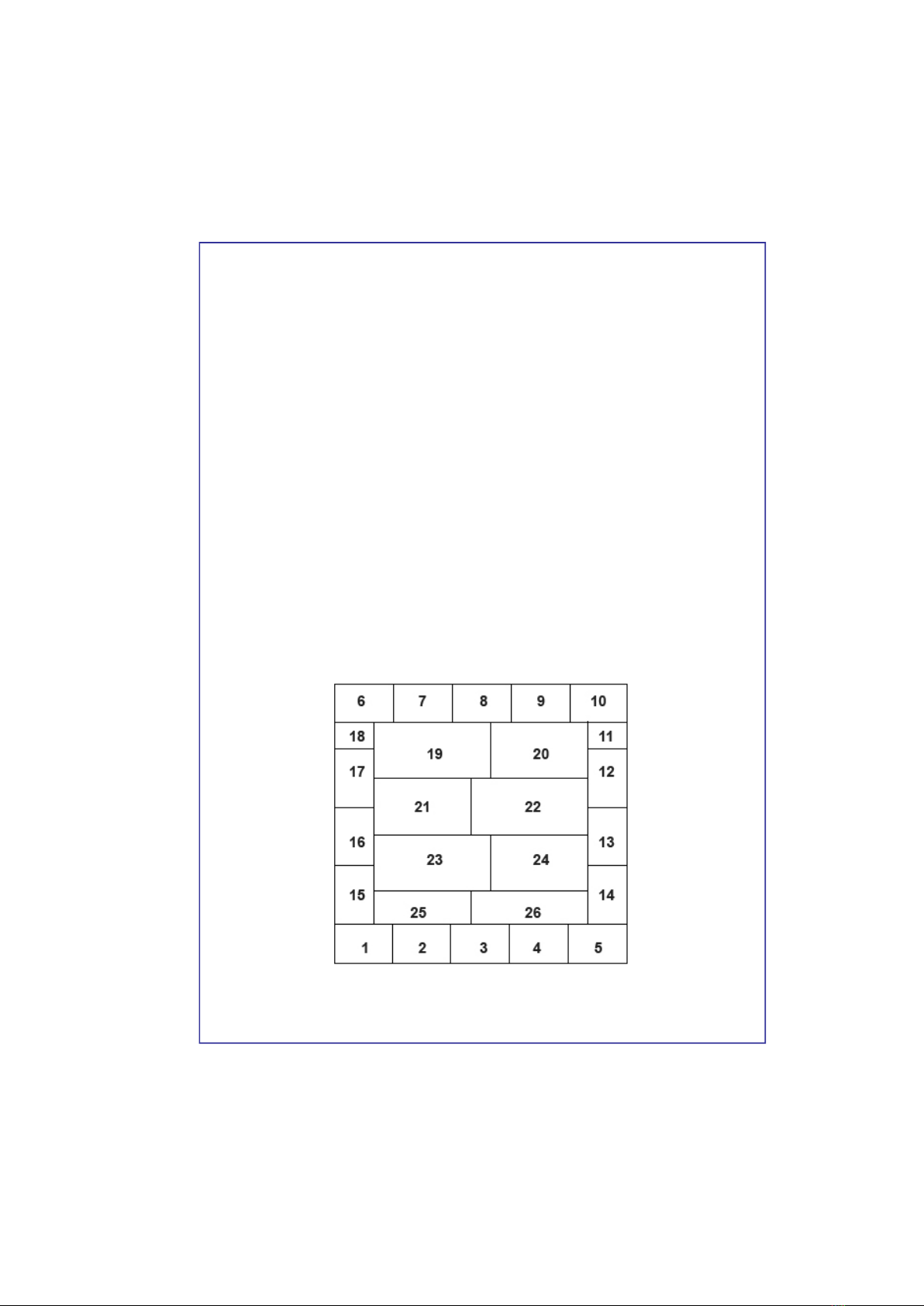

Firstly, unplug the kiln from the electrical supply then unscrew the two side

cover boxes that cover the element connections and let them hinge

downwards. It is now possible to replace the elements with the side boxes in

the lowered position and still attached to the kiln lid. If the cover boxes do need

to be removed take extreme care so as to not let the power cables pull at the

element tubes.

When it is determined which element has blown, (for this a circuit tester may be

required). There are three elements in the Hobbyfuser 3, each element

consists of a pair of tubes.

Disconnect both ends of the elements from their porcelain connector blocks.

Now slide out the element and both tubes out as one.

IMPORTANT. For this step it is strongly advised that the room is ventilated and

that a suitable P3 standard respiratory mask is used.

Never handle the element tubes with bare hands, use the disposable gloves

provided. From the left hand side of the kiln slide in the new element.

Take care and be gentle, even though the tubes have a high strength once in

position, they can be chipped or crack if handled carelessly.

Once the element is through both sides of the case then level up the element

and tubes so that the element which is visible through the tube is sitting central

in the roof space with the gap between the element and the fibre wall of the lid

being the same on both sides.

Before connection it is worth checking on the non-connection side of the kiln lid

that the element has stayed fully inserted into the tube, if not then apply gentle

pressure to the element where it links the two tubes together and ease the

element back to its fully inserted position in the tube.

Reconnect the element tails to each porcelain block as before.

Again take care to hold the porcelain connector block steady as you re-connect

to avoid cracking the end of the tube.

Re-fit both side cover boxes ensuring that any wires present are clear of the

protruding element tubes and connector blocks.

A slight odour will be emitted during the first firing as the element burns out

binders in the element seal compound.