Linear scale ranges -1999 to 9999 (with 4 digit display)

-999 to 999 (with 3 digit display - only for model 96)

Configurable decimal point position

For correct and safe

installation, follow the

instructions and

observe the warnings

contained in this

manual.

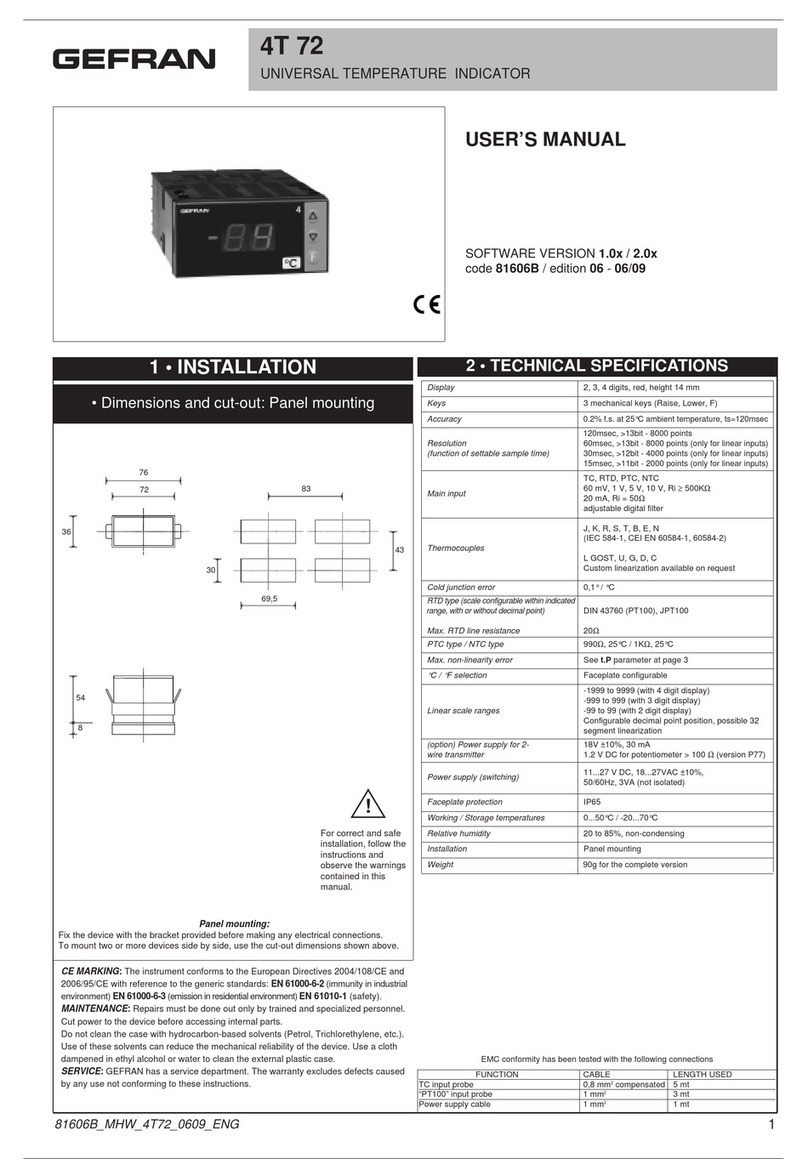

1 • INSTALLATION

• Dimensions and cut-out: Panel mounting

Panel mounting:

Fix the device with the bracket provided before making any electrical connections.

To mount two or more devices side by side, use the cut-out dimensions shown above.

CE MARKING: EMC (electromagnetic compatibility) conformity to EEC Directive

89/336/CEE with reference to the generic Standard EN61000-6-2 (immunity in

industrial environments) and EN50081-1 (emission in residential environments).

BT (low voltage) conformity to Directive 73/23/CEE as modified by Directive 93/68.

MAINTENANCE: Repairs must be done out only by trained and specialized personnel.

Cut power to the device before accessing internal parts.

Do not clean the case with hydrocarbon-based solvents (Petrol, Trichlorethylene, etc.).

Use of these solvents can reduce the mechanical reliability of the device. Use a cloth

dampened in ethyl alcohol or water to clean the external plastic case.

SERVICE: GEFRAN has a service department. The warranty excludes defects caused

by any use not conforming to these instructions.

2 •TECHNICAL SPECIFICATIONS

FUNCTION CABLE LENGTH USED

Input 1 mm23 m

Power supply cable 1 mm21 m

EMC conformity has been tested with the following connections

!

6

4A 48 / 4A 96

CONFIGURABLE ALTERNATING CURRENT AND VOLTAGE INDICATOR

SOFTWARE VERSION 1.0x / 2.0x

code 81621B / edition 06 - 03/04

USER’S MANUAL

Faceplate protection IP65

Working / Storage temperatures 0 to 50°C / -20 to 70°C

Relative humidity 20 to 85%, non-condensing

Installation Panel mounting, extractable from front

Weight

150g (mod. 48); 280g (mod. 96) for the complete version

Resolution >13-bit, 8000 points

Fuse (inside device, not

operator serviceable) 100 to 240Vac/dc - type T - 500mA - 250V

11 to 27Vac/dc - type T - 1,25A - 250V

Power supply (switching)

4A 48

(standard) 100 to 240Vac ±10% - 3,5VA

(optional) 20 to 27Vac/dc ±10% - 3,5VA

4A 96

(standard) 100 to 240Vac/dc ±10% - 5VA

(optional) 11 to 27Vac/dc ±10% - 3VA

50/60Hz

Display

3, 4 digit red LED’s

mod. 48 digit height 10mm (4 digits)

mod. 96 digit height 20mm (3 digits),

digit height 14mm (4 digits)

Keys 3 mechanical keys (Raise, Lower, F)

Accuracy

0.2% f.s. for 2 Vac, 20 Vac, 20mAac inputs

50mAac, 1Aac, at room temperature of 25°C

0.5% f.s. for 200Vac, 500Vac, 200mAac, 5Aac

inputs, values shown are for max. rms value with

sine wave signal

Main input

2Vac, 20Vac, 200Vac, 500Vac, Ri ≥1MΩ

Max. continuous voltage = 600Vac

Max. voltage for 1 minute = 900Vac

Voltage pulse 1,2/50µs = 2KVpeak

20mAac, 50mAac, 200mAac, Ri = 1,6Ω

Max. continuous current = 400mAac at 50°C

1Aac, 5Aac, Ri = 16mΩ

Max. continuous current = 5.5Aac at 50°C

Max. frequency = 60Hz

Environmental conditions of use for internal use only, altitude up to 2000m