SAFETY /

SPECIFICATIONS

ASSEMBLY /

INSTALLATION OPERATION TROUBLESHOOTING MAINTENANCE /

REPAIR

GETTING STARTED

tools.eps

box.eps

magnify_2.eps

warning symbol.eps

measure.eps

plug.eps

oil.eps

megaphone.eps

biohaz.eps

Battery_Caution1.eps

Caution.eps

Crush_Caution1.eps

Electrical_Caution.eps

Face_protection.eps

Fall_Hazard.eps

Fall_protection.eps

GearHand_Hazard.eps

Head_protection.eps

Heavy_Hazard.eps

Hot_surface.eps

Recycle.eps

Resp_protection1.eps

Resp_protection2.eps

Temp_Caution1.eps

body_protection.eps

chemical_Caution.eps

ear_protection1.eps

explosive_caution.eps

eye_protection1.eps

foot_protection.eps

hand_protection.eps

tools.eps

box.eps

magnify_2.eps

warning symbol.eps

measure.eps

plug.eps

oil.eps

megaphone.eps

biohaz.eps

Battery_Caution1.eps

Caution.eps

Crush_Caution1.eps

Electrical_Caution.eps

Face_protection.eps

Fall_Hazard.eps

Fall_protection.eps

GearHand_Hazard.eps

Head_protection.eps

Heavy_Hazard.eps

Hot_surface.eps

Recycle.eps

Resp_protection1.eps

Resp_protection2.eps

Temp_Caution1.eps

body_protection.eps

chemical_Caution.eps

ear_protection1.eps

explosive_caution.eps

eye_protection1.eps

foot_protection.eps

hand_protection.eps

tools.eps

box.eps

magnify_2.eps

warning symbol.eps

measure.eps

plug.eps

oil.eps

megaphone.eps

biohaz.eps

Battery_Caution1.eps

Caution.eps

Crush_Caution1.eps

Electrical_Caution.eps

Face_protection.eps

Fall_Hazard.eps

Fall_protection.eps

GearHand_Hazard.eps

Head_protection.eps

Heavy_Hazard.eps

Hot_surface.eps

Recycle.eps

Resp_protection1.eps

Resp_protection2.eps

Temp_Caution1.eps

body_protection.eps

chemical_Caution.eps

ear_protection1.eps

explosive_caution.eps

eye_protection1.eps

foot_protection.eps

hand_protection.eps

tools.eps

box.eps

magnify_2.eps

warning symbol.eps

measure.eps

plug.eps

oil.eps

megaphone.eps

biohaz.eps

Battery_Caution1.eps

Caution.eps

Crush_Caution1.eps

Electrical_Caution.eps

Face_protection.eps

Fall_Hazard.eps

Fall_protection.eps

GearHand_Hazard.eps

Head_protection.eps

Heavy_Hazard.eps

Hot_surface.eps

Recycle.eps

Resp_protection1.eps

Resp_protection2.eps

Temp_Caution1.eps

body_protection.eps

chemical_Caution.eps

ear_protection1.eps

explosive_caution.eps

eye_protection1.eps

foot_protection.eps

hand_protection.eps

BEFORE YOU BEGIN

Usage Requirements

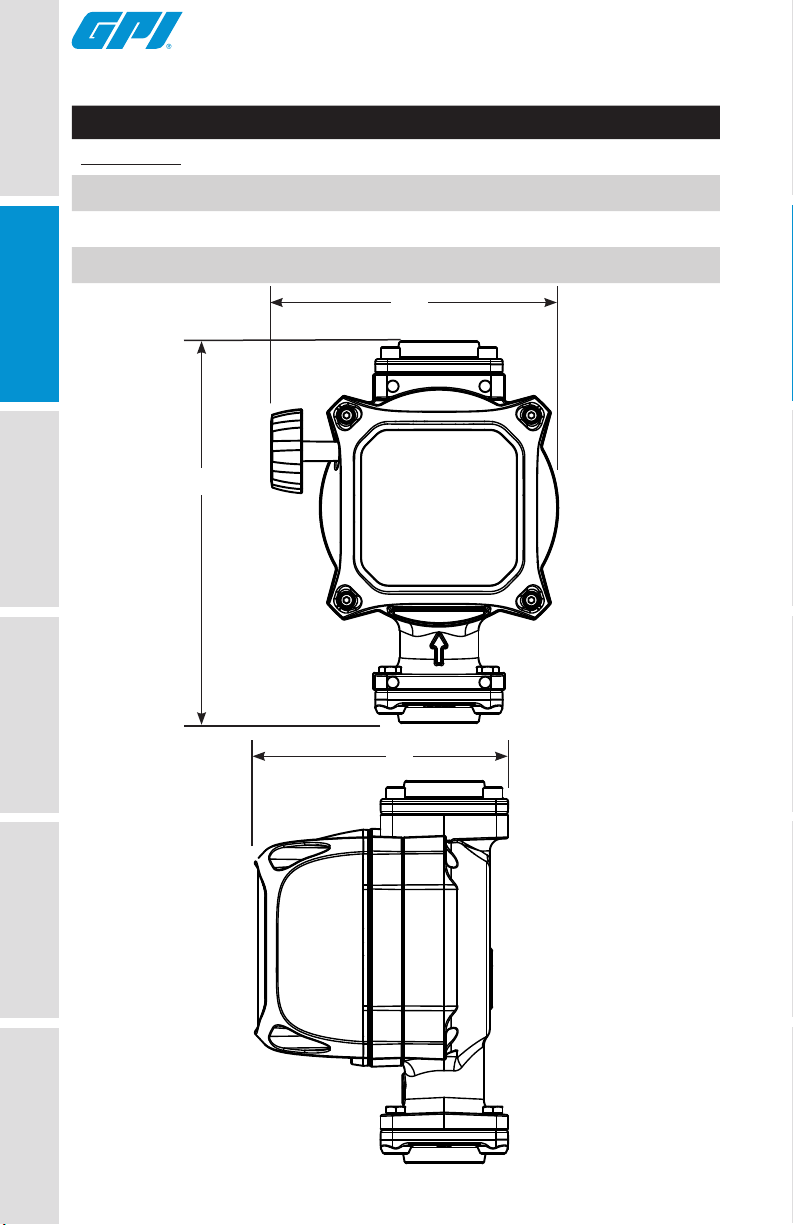

• This manual covers fuel meter models M30-G8N and M30-L8N

• This fuel meter is designed, tested and approved for use with thin

viscosity petroleum fuels such as gasoline blends (up to E15), diesel

fuel blends (up to B20) and kerosene.

Please take all due precautions when handling these flammable liquids.

• Do not use this meter for measuring any fluids other than those for

which it was designed. To do so may damage the meters’ components

and will void the warranty.

• The M30 Mechanical Fuel Meter is designed for the field measurement

of thin viscosity petroleum fuels only and intended for use with pump

systems in the 5 to 30 GPM or 19 to 114 L/m flow range (not intended

for gravity flow systems). Using mechanical gears, these meters

translate flow data from a nutating disk into calibrated units which are

indicated on the face of the meter. This meter is factory calibrated for

diesel fuel. A field calibration feature is available for other fluids (see

Calibration section).

Tools Needed

• 10mm Open-end Wrench, Hex Wrenches (Hex Keys, 3mm & 5mm),

Thread Tape pr Pipe Thread Sealing Compound (approved for use with

flammable liquids)

UNPACKING

Contents

• (1) Nutating Disc Fuel Meter, U.S. Gallon or Litre Version

• (1) Register Knob

• (1) 1 in. NPT Inlet Fitting with O-ring and mounting screws

• (1) 1 in. NPT Outlet Fitting with O-ring and mounting screws

Inspect

• After unpacking the unit, inspect carefully for any damage that may

have occurred during transit. Check for loose, missing or damaged

parts. Shipping damage claims must be filed with carrier.

• Review General Safety Instructions and all Caution, Warning, and

Danger statements as shown.

3