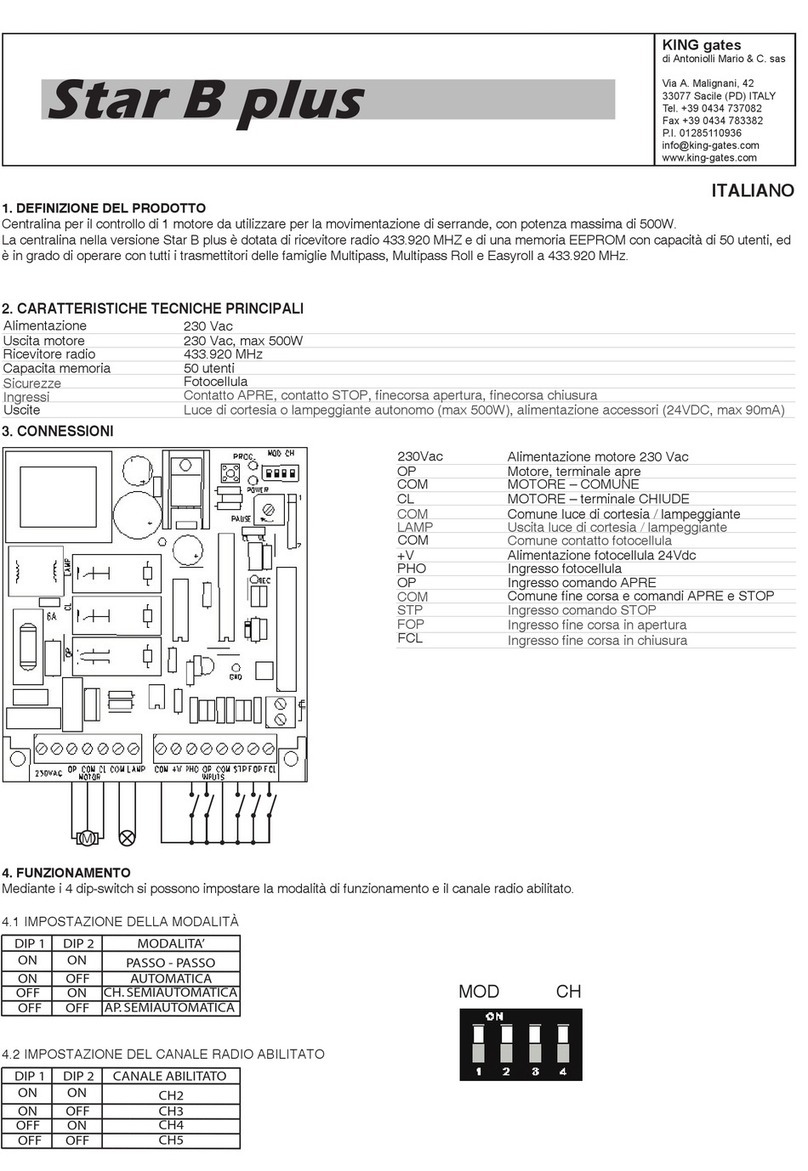

Power/Speed (POWER):

Regulation from 50% to 100% of the power to the motor.

This parameter will also weigh on the manoeuvre speed.

Length of the prelamp (LAMP):

Regulation of the prelamp before every manoeuvre

customizable from 0 to 5 seconds.

Pause time (PAUSE):

Regulation of pause time at the end of the manoeuvre, before the

automatic reclosing from 0 to 90 seconds. The “AUTO” dip switch

must be ON.

Obstacle sensitivity (OBSTACLE):

Regulation of intervention time from 0.1 to 3 seconds.

The lower the trimmer is regulated, earlier the central will stop the

automation in case of impact of the wing against an obstacle.

4 - CONTROL UNIT SETTINGS

MAX

MAX

MAX

MAX

A variation on the DIP position does not require a another programming procedure.

A variation on the setting of “FOR” trimmer (power/speed) requires the repetition of the learning

procedure (point 2), because of the change of the manoeuvre time. The slowdowns are automatically set in

the last 15% of the travel.

4B - TRIMMER SETTINGS

4A - DIP-SWITCHES SETTINGS

DIP

1

ON

OFF

ON

OFF

ON

OFF

2

3

ON

OFF

4

ON

OFF

5

ON

OFF

6

ON

OFF

7

ON

OFF

8

DIP STATUS FUNCTIONINGDESCRIPTION

Opening / Stop / Closing / Stop modality (step by step)

Opening / Pause / Closing (it accepts only opening commands)

STEP

Yes automatic reclosing (set by “PAU” trimmer)

No automatic reclosing

AUTO

Stop and it recloses for 2 seconds in opening (PHO2, working as pneumatic edge)

Stop and it keeps on opening after clearing in opening (PHO2 , working as photocell)

PHO 2

Flashing light

Steady light

LAMP

STRIKE

Yes rapid automatic reclosing

No rapid automatic reclosing

FAST

START radio channel programming procedure (see paragraph 3A)

Pedestrian opening radio channel programming procedure (see paragraph 3B)

RADIO

Slowdown enabled

Slowdown disabled

SLOW

If the “SLOW” dip-switch is set to ON, the control unit enables the slowdowns. Using the standard programming procedure, they

are equal to the 15% of the travel, but they can be customized by the professional programming procedure (see paragraph 6D).

If the “SLOW” dip-switch is set to OFF, the control unit disables the slowdowns.

5 - DIP-SWITCHES DESCRIPTION

5H - DIP-SWITCH 8 - SLOW

If the “STEP” dip-switch is set to ON, the step-by-step function is enabled. Every time the control unit receives an input signal, it

perform an action. When the automation is stationary, it starts the motor, and when the automation is moving, it stops the motor.

If the “STEP” dip-switch is set to OFF, the modality OPEN/STOP/CLOSING is enabled. The control unit accepts only commands

(by wire or by transmitter) in opening. So, when the gate is closed, it opens. When the gate is opening, it keeps opening, and

when the gate is closing, it opens completely.

The reclosing takes place with the time set by the “PAU” trimmer, if the “AUTO” dip is set to ON.

Otherwise, it is necessary to give a START command (by wire or by transmitter).

5G - DIP-SWITCH 7 - STEP

If the “AUTO” dip-switch is set to ON, the automatic reclosing function is enabled. The control unit automatically closes the wing

after the time set by the “PAU” trimmer (see paragraph 4B).

If the “AUTO” dip-switch is set to OFF, the automatic reclosing function is disabled. It is necessary to supply a command (by

wire or by transmitter) to close the wing.

5F - DIP-SWITCH 6 - AUTO

If the “PHO2” dip-switch is set to ON, the safety devices in opening and closing, when they intervene, stop the motion of the

wing, which will open again as soon as cleared (typical functioning of the photocell).

If the “PHO2” dip-switch is set to OFF, the safety devices in opening, when they intervene, invert the motion for 2 seconds, and

then they stop the automation. So, it is necessary to supply a command (by wire or by transmitter) to finish the travel, and close

the wing (typical functioning of the safety edge). With this setting these safety devices in closing do not intervene.

5E - DIP-SWITCH 5 - PHO2 (see also paragraph 11B)

If the “LAMP” dip-switch is set to ON, the power supply given to the lamp (terminals 8,9) is intermittent (see paragraph 12A).

If the “LAMP” dip-switch is set to OFF, the power supply given to the lamp (terminals 8,9) is direct (see paragraph 12A).

5D - DIP-SWITCH 4 - LAMP (see also paragraph 12A)

If the “STRIKE” dip-switch is set to ON, the kick-back is enabled (see paragraph 12D). In this way, the control unit will supply a

voltage swing at the beginning of the opening cycle, and at the end of the closing cycle.

If the “STRIKE” dip-switch is set to OFF, the kick-back is disabled.

5C - DIP-SWITCH 3 - STRIKE (see also paragraph 12D)

If the “FAST” dip-switch is set to ON, the rapid reclosing is enabled. This modality enables to reclose the gate as soon as the

control unit notices that the photocell range have been occupied and cleared. So, going through the passage, the automatic

reclosing of the automation will be enabled, without waiting the pause time.

If the “FAST” dip-switch is set to OFF, the automatic reclosing is disabled

5B - DIP-SWITCH 2 - FAST

If the “RADIO” dip-switch is set to ON, the START channel is memorized during the programming of the radio transmitter (see

paragraph 3).

If the “RADIO” dip-switch is set to OFF, the pedestrian opening channel is memorized during the programming of the radio

transmitter (see paragraph 3).

5A - DIP-SWITCH 1 - RADIO

Kick-back enabled

Kick-back disabled