1

EN

1. Product description

1.1 - Commissioning

To start-up the system, the following steps must be carried out:

1 - Check cabling, tighten all connections and terminals. Follow

cabling standards and regulations of the country/region.

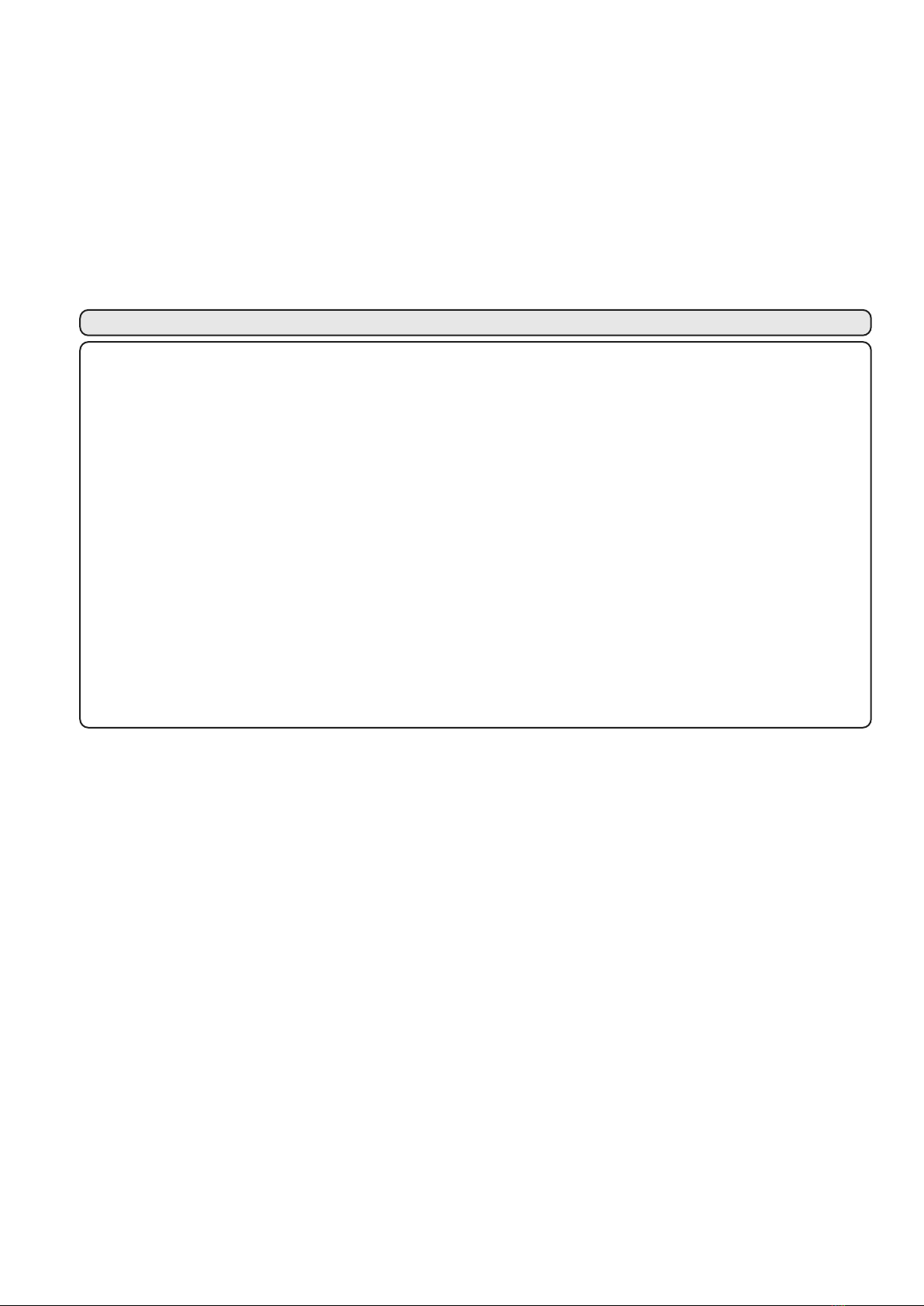

2 - Set the dip switches (par. 3.1) and knobs (par. 3.2) according to

-

tion.

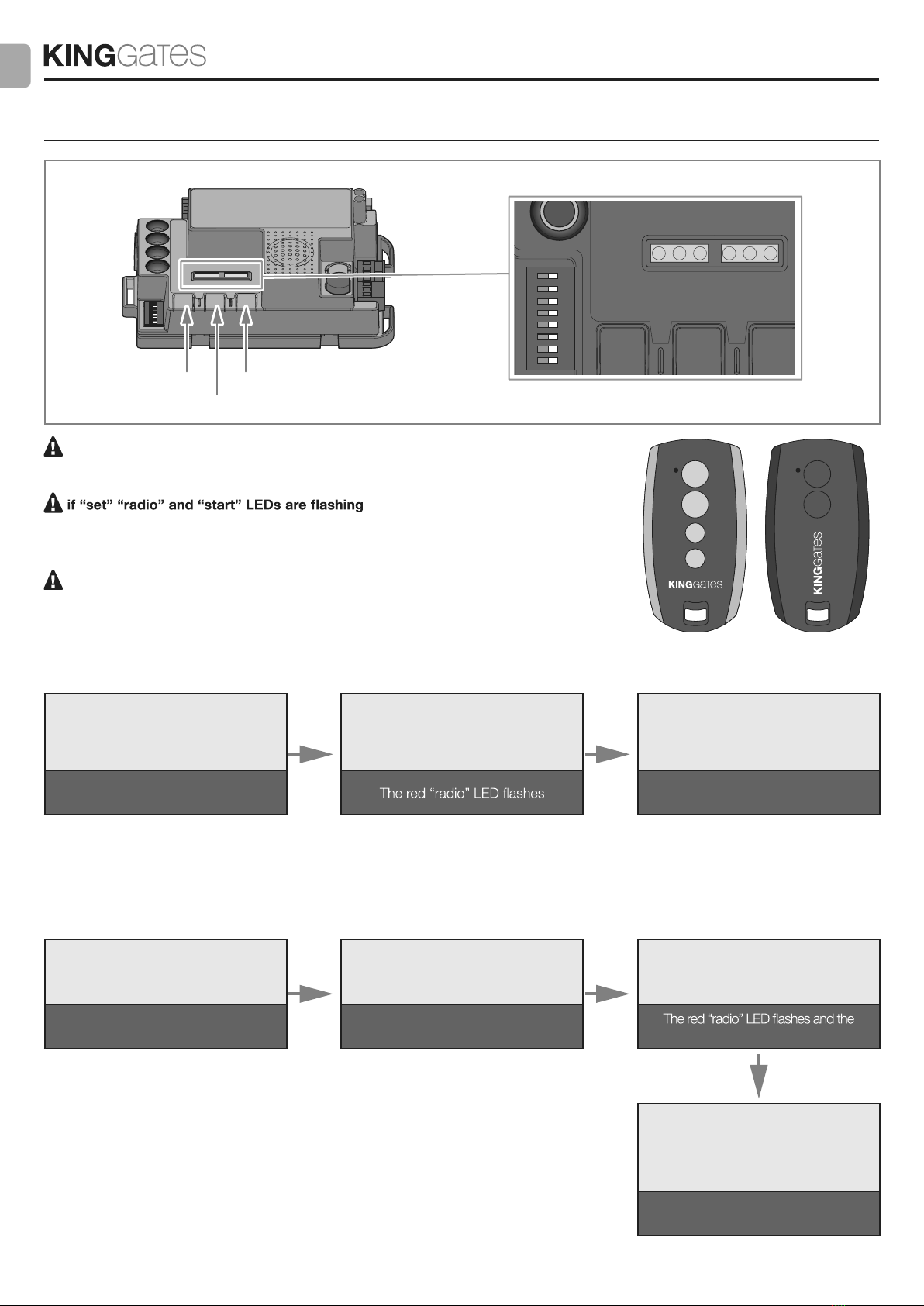

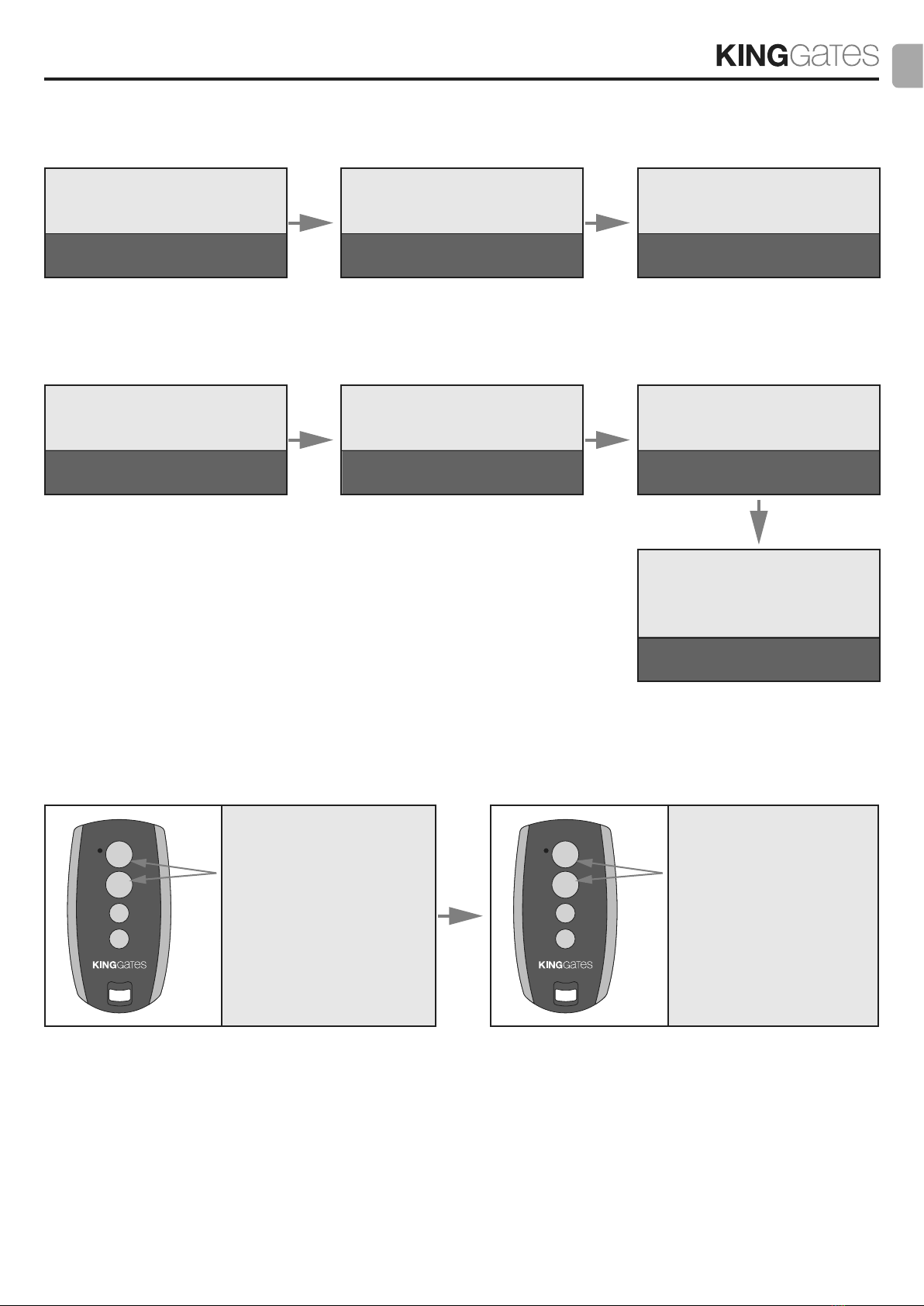

3 - Memorise the transmitters (Paragraph 4).

4 - Programme the gate travel path (Paragraph 5) so that the .

control unit learns the gates open and close points.

5 - Perform the checks described in the “Testing and commissioning”

paragraph (Paragraph 6).

If, after completing these steps, the control unit should

malfunction, consult Paragraph 7, “LEDs indication”, to iden-

tify any issues, and Paragraph 9, “Troubleshooting”, to attempt

to solve it.

1.2 - Main Features

- Flasher control with/without integrated intermittency function (Par-

agraph 9.3).

- Integrated management for electric locks 24V max. 15VA (Para-

graph 9.4).

This output can also be used to control courtesy lights (Paragraph 13).

-

Double NC input for opening and closing limit switch (Paragraph 9.8).

- Inputs for start, stop and pedestrian opening wired commands,

customisable to open, stop and close (Paragraph 9.9).

- Double input for safety devices: “PHO1” during closing and “PHO2”

during closing and/or opening (Paragraph 9.5).

- Possibility of powering 24VDC accessories (Paragraph 9.6).

- Input for gate status pilot light signalling the position of the leaves

(Paragraph 9.7).

- Input for external antenna that can be used for increasing the

range of the transmitters (Paragraph 9.10).

- Staggered closing of gate leaves adjustable through the knob (Par-

agraph 3.2).

- Pause time for automatic re-closing adjustable to between 0 and

180 sec. with knob (Paragraph 3.2).

- Obstacle sensitivity adjustment with knob (Paragraph 3.2).

- Motor force adjustment with knob (Paragraph 3.2).

- Incorporated radio receiver (433.92MHz), compatible with King-

Gates rolling transmitters.

- 6 indication LEDs (Paragraph 7).

- Slow-speed opening and closing (customisable through dedicated

programming).

1.3 - Technical features of the

control unit

Mains power supply* 230 Vac ±10%, 50 - 60 Hz

Motor power supply 24V DC 280W and 10A peak

motor

Warning light power supply 24V max 15W

Gate pilot lamp power supply 24Vdc max 10 W

Accessories’ power supply

(photocells...) 24 Vdc max 10 W

Radio receiver frequency433.920 MHz

Storable remote controls 170

Radio antenna input RG58

Operating temperature -20 ÷ 50 °C

- Automated access command for 1 or 2 24V motors.

fffoooeeepppyyyttteeehhhtttyyyfffiiiccceeepppsssooowwwtttdddnnnaaaeeennnooohhhccctttiiiwwwssspppiiidddfffooonnnoooiiitttaaarrruuugggiiifffnnnoooCCC

eeesssuuunnniiirrroootttooommm