battery.

(c)Unplug the plug of power supply, plug the plug of charger into the plug of power

supply of battery.

(d)Switch on alternating current and start charging by the charger。

Notice!

Keep favourable ventilation when charging, especially in close zone. During the

process of charging, battery produces hydrogen, oxygen that triggers explosion so

long as mixing with open fire and electric sparks.

Cut off charging power supply before unplugging the plug of power supply.

4、Charging Period

During the process of charging, the following methods by which we can draw a

conclusion whether the battery charged is sufficient to electric quantity.

(a)The specific gravity of electrolyte of battery keeps stable in more than 2~3 hours.

(b)The surface of battery electrolyte produces bubble, the colour of electrolyte has

been become clear from milky white.

The above conditions indicate the electric capacity of battery has been sufficient by

charging.

5、After the completion of battery charging

(a)Power off alternating power supply, as well as charger.

(b)Unplug the charger plug from the plug of battery.

(c)Turn key switch to turn-off position, plug the power-supply plug of battery into

the vehicle-body plug of battery.

(d)Close the vent caps of battery.

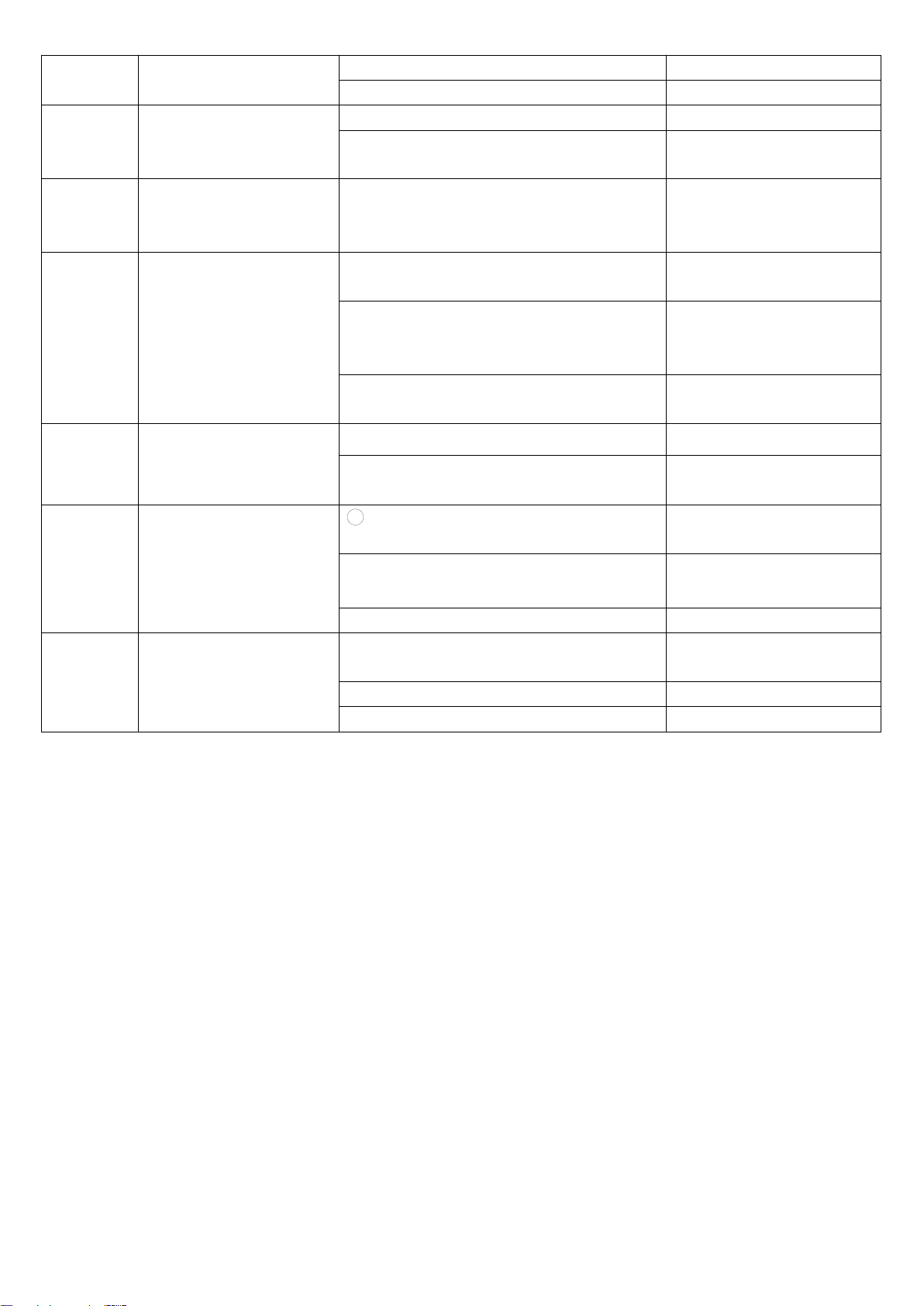

The sufficient-electric-capacity battery comparison table between its temperature

and its specific gravity of electrolyte as below:

Add acid liquor or distilled water to adjust if inconformity to the specific gravity out of

the table.

Upkeep of Storage Battery

1、In order to keep the use life of storage battery, the battery should be charged fully

before come into use, undercharged battery may not to be used.

2、Storage battery avoids overcharge and over-discharge as much as possible,

overcharge and over-discharge heavily affect the use life of storage battery.

3. Keep clean to the electrolyte solution’s pore plug & vent lids, take them off or open

them when charging, fit them on or close them when charging completion. Keep

clean and dry to the surface, connecting wire and screws of storage battery. Use