7

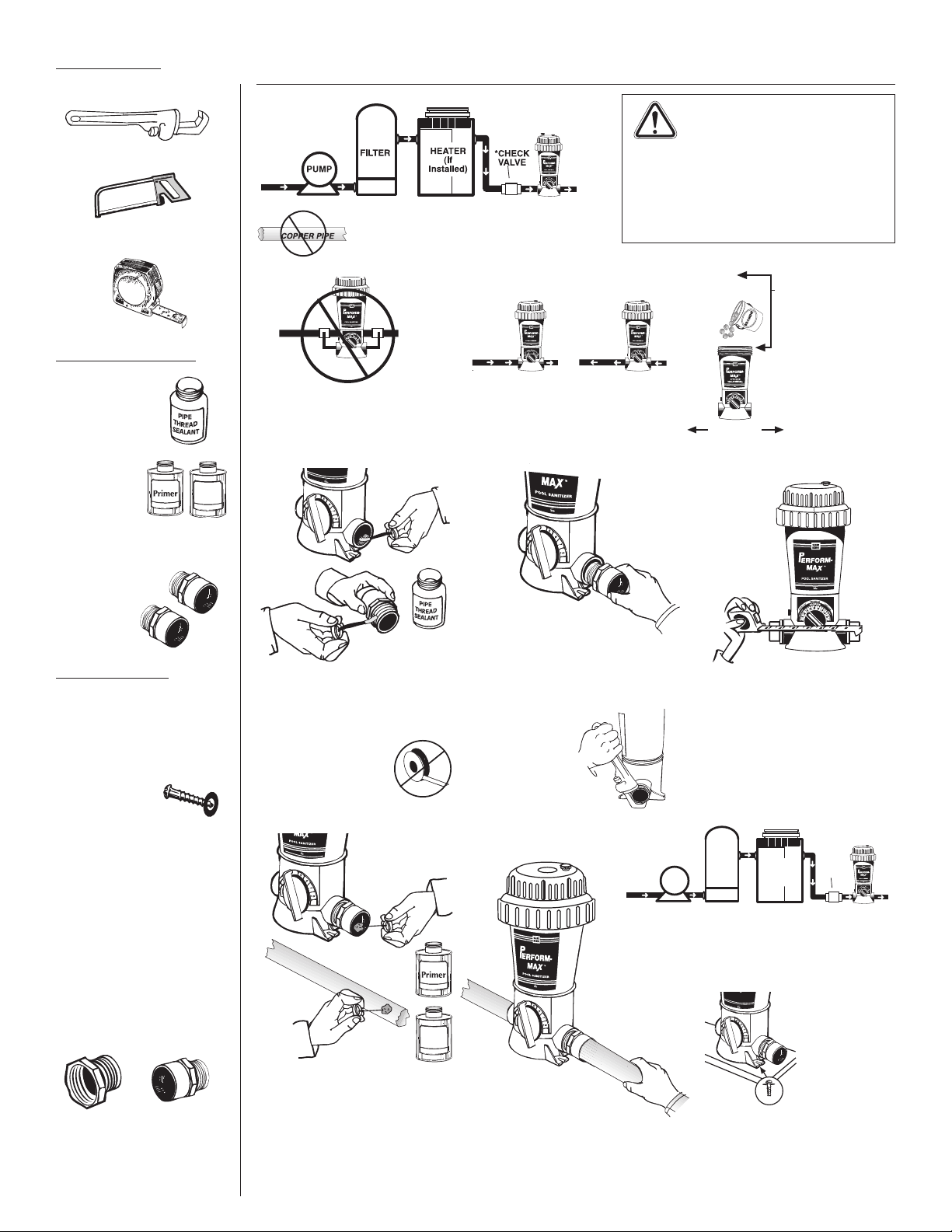

TO POOL

PUMP

FILTER

TOOLS NEEDED

Screwdriver

Pipe Wrench

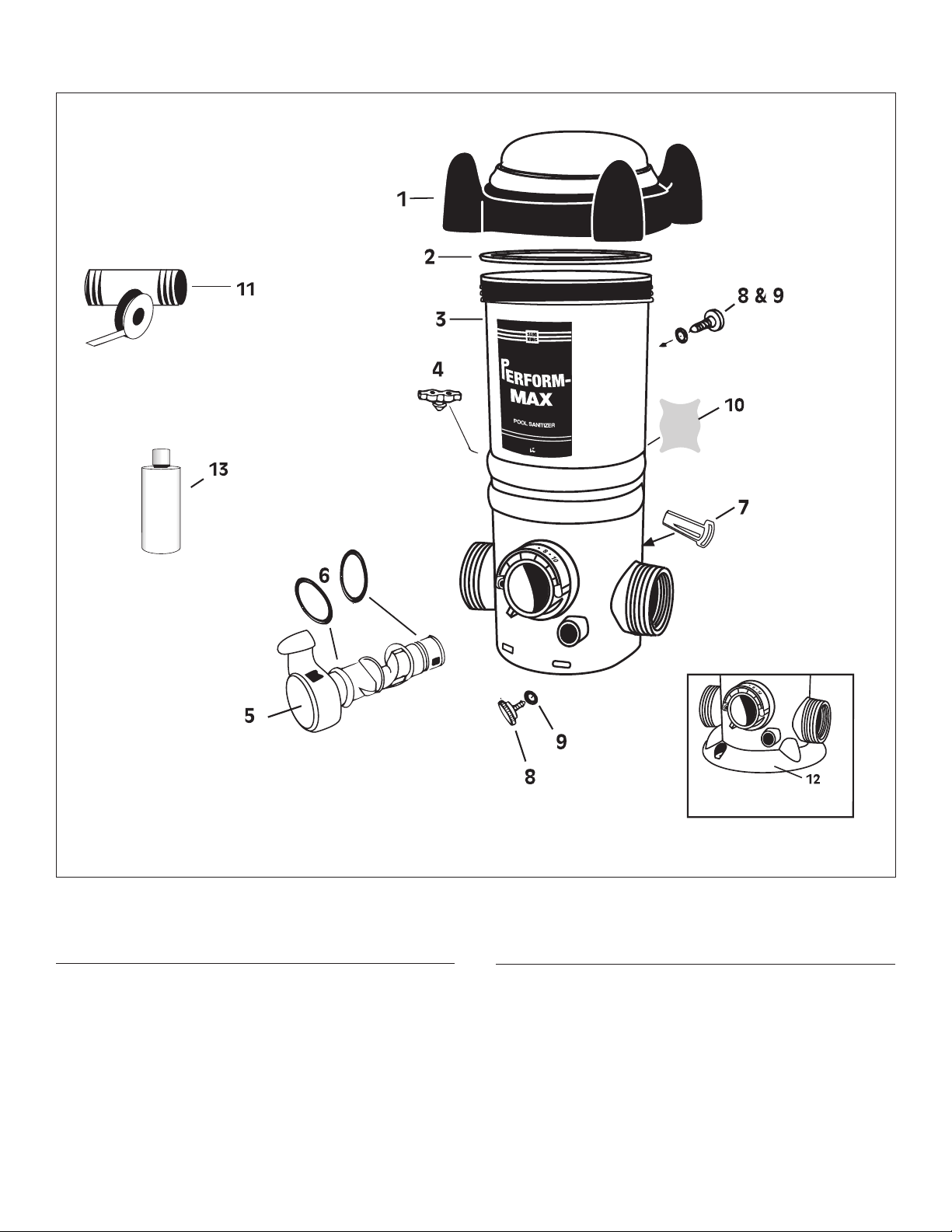

Materials Needed

Pipe Thread Tape

or Sealant

Two hose adapters

1 1/2” x 1 1/2” x 1 1/4”

Two Sections of 1 1/2”

Flex Hose (one provided

with filter)

Two

Hose

Clamps

Recommended

Corrosion Resistant

Check Valve

4-8 psi Back Pressure

To avoid over or under chlorination,

replace eye ball fittings in the return

jets to a smaller or larger size to

adjust back pressure.

10 x 1 1/4” Phillips

Pan Head Screws with

Washers

Apply pipe thread tape or

sealant to the threaded end of

both hose adapters.

1.

The Perform-Max should always be installed

between the filter and pool (or between heater

and pool if applicable).

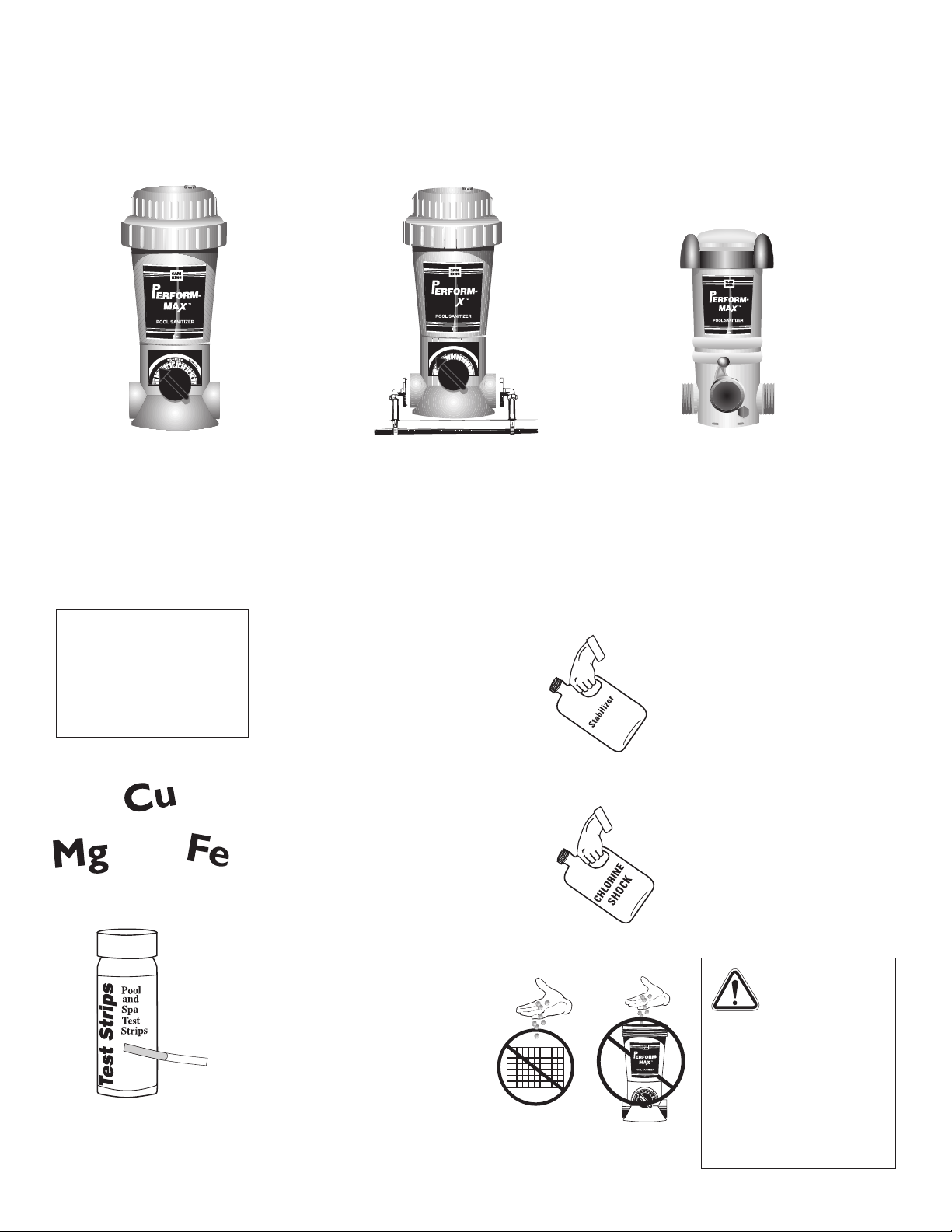

Above Ground, Base Installation - Model 920

Screw adapters into each end of

Perform-Max Hand tighten. Finish

tightening by turning 1 to 2 revolutions

with wrench.

DO NOT OVER TIGHTEN.

2.

Attach the filter section of flex hose to one hose

adapter and the return section of flex hose to the other

hose adapter with clamps and tighten with screwdriver.

Bi-flow valve design allows water flow in either direction.

3.

Isolating the Perform-Max by installing a corrosion

resistant check valve is recommended.

4.

If you prefer to mount this

unit there is an additional

base part available - PN#

01-22-1480. Mount using

Phillips Pan head screws.

One in front and two in

back.

5.

REPLACEMENT PARTS • Model 960

REF. # PART NUMBER DESCRIPTION

11 01-22-9490 2” Male Adapter

12 01-22-8620 2” X 1/2” Bushing

13 01-22-7800 90 Degree Elbow

14 01-22-7690 Small Clamp

15 01-22-7700 6’ PVC Tubing

16 01-22-7850 Scoop Gasket

17 01-22-7790 Venturi Scoop

18 01-22-7910 Scoop Clamp

Option

1 1/2” Male Adapter

(slip x MPT)

or

2” Female Adapter

(slip x FPT)

When installing with hard

PVC pipe, use either a female

adapter on the outside port

threads or a male adapter on

the inside port threads.

CHECK

VALV E

BUSHING

HOSE

CLAMP

HOSE

ADAPTER HOSE

CLAMP

HOSE

ADAPTER

TO POOL

1 1/2" OR 1 1/4"

FLEX HOSE

1 1/2" x 1 1/2" x 1 1/4"

HOSE ADAPTER

HOSE

CLAMP

FILTER &

PUMP

• Install after all equipment and

as far as possible from heater.

• Any additional sanitizing

equipment that is installed with

Perform-Max must be installed after

Perform-Max (never before) on the

return line to the pool.