R1040 MAINTENANCE MANUAL

Page 8 of 48

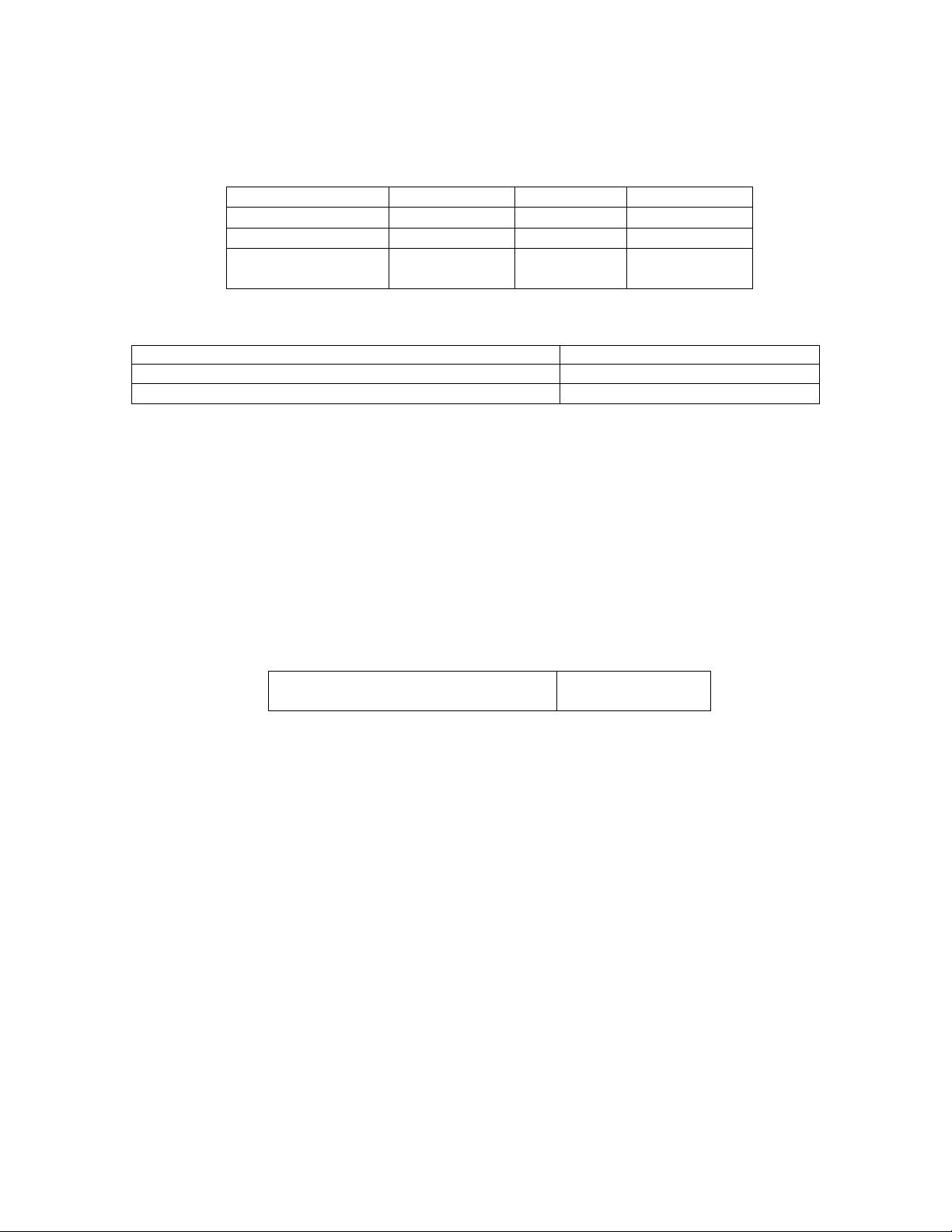

These capacities are for the standard cast iron and standard sheet metal sumps.

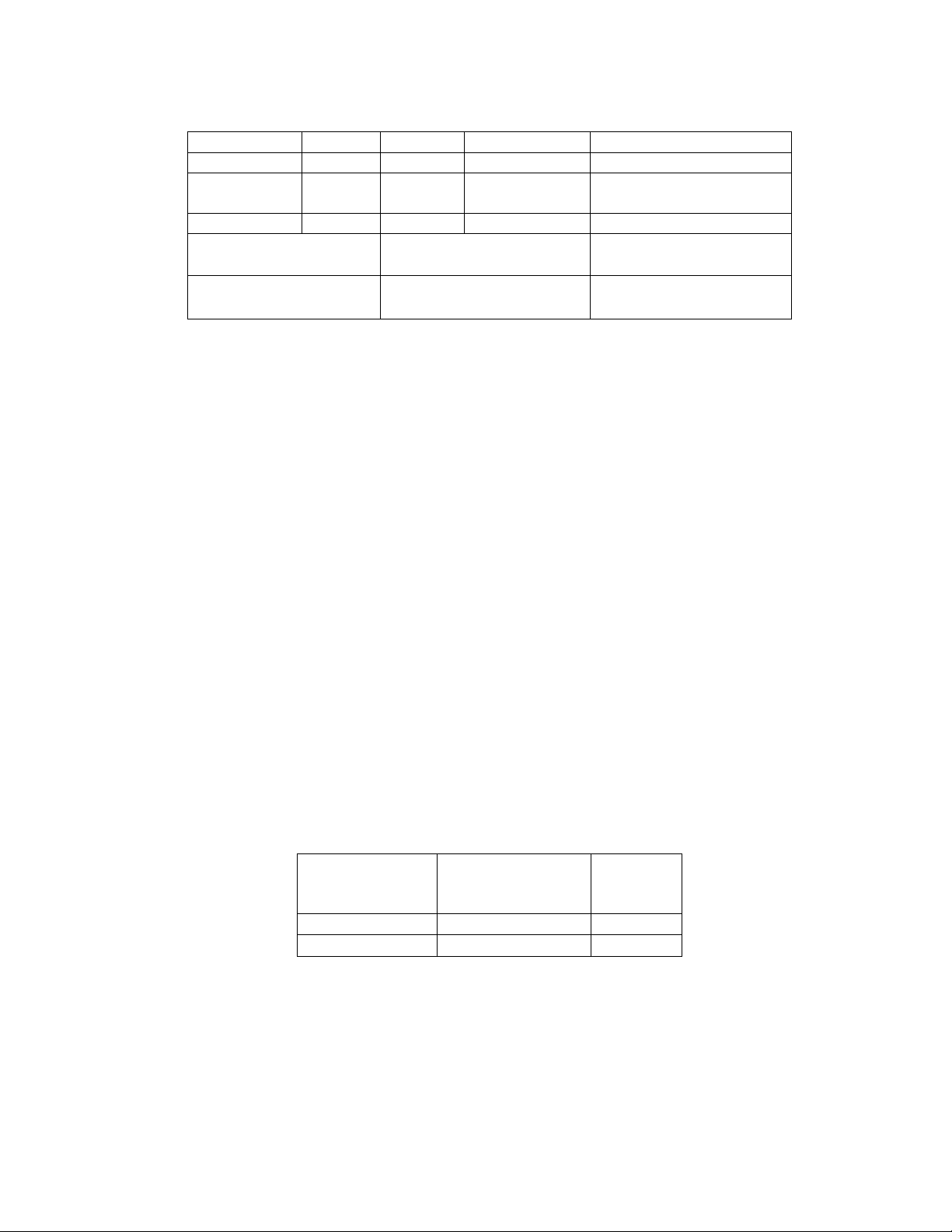

Engine type 2R1040 3R1040 4R1040/T/TA 6R1080/T/TA

Oil sump type S.M. S.M. S.M. S.M.

Initial fill

(lit.)

5.5 9 11.5 15

Refill (lit.) 4.5 7.5 9.5 13.5

Oil Specifications

Oil change period (Hours)

To be used for

MIL-L-2104 C PLUS

CF4, D4, D5

400 Naturally aspirated as well

as Turbo charged engines

The oil must be changed at least once in a year. This is applicable to the engines, which are

running for standby duty application.

The above oil change period is subject to following conditions.

•

The minimum ambient temperature should not less than – 10

0

C.

Please contact your distributor for change in the ambient temp condition.

Note:

First fill = Sump capacity + Gallery capacity + Lube oil filter capacity

Fill the oil Lube oil filter before fitting on the engine.

Do not forget to fill the Lube oil filter whenever you replace the filter.

Whenever Lube oil filter is drained off, add approximately 0.5 lit. /1 lit.extra Lube oil

(as per the size of the Spin-on filter cartridge) in the sump to maintain the correct oil

level.)

The oil level in the sump should be checked at room temperature by using dipstick.

Top up with fresh oil when the level reaches the low level mark on dip stick, fill till it

increases to top level mark. Avoid over filling.

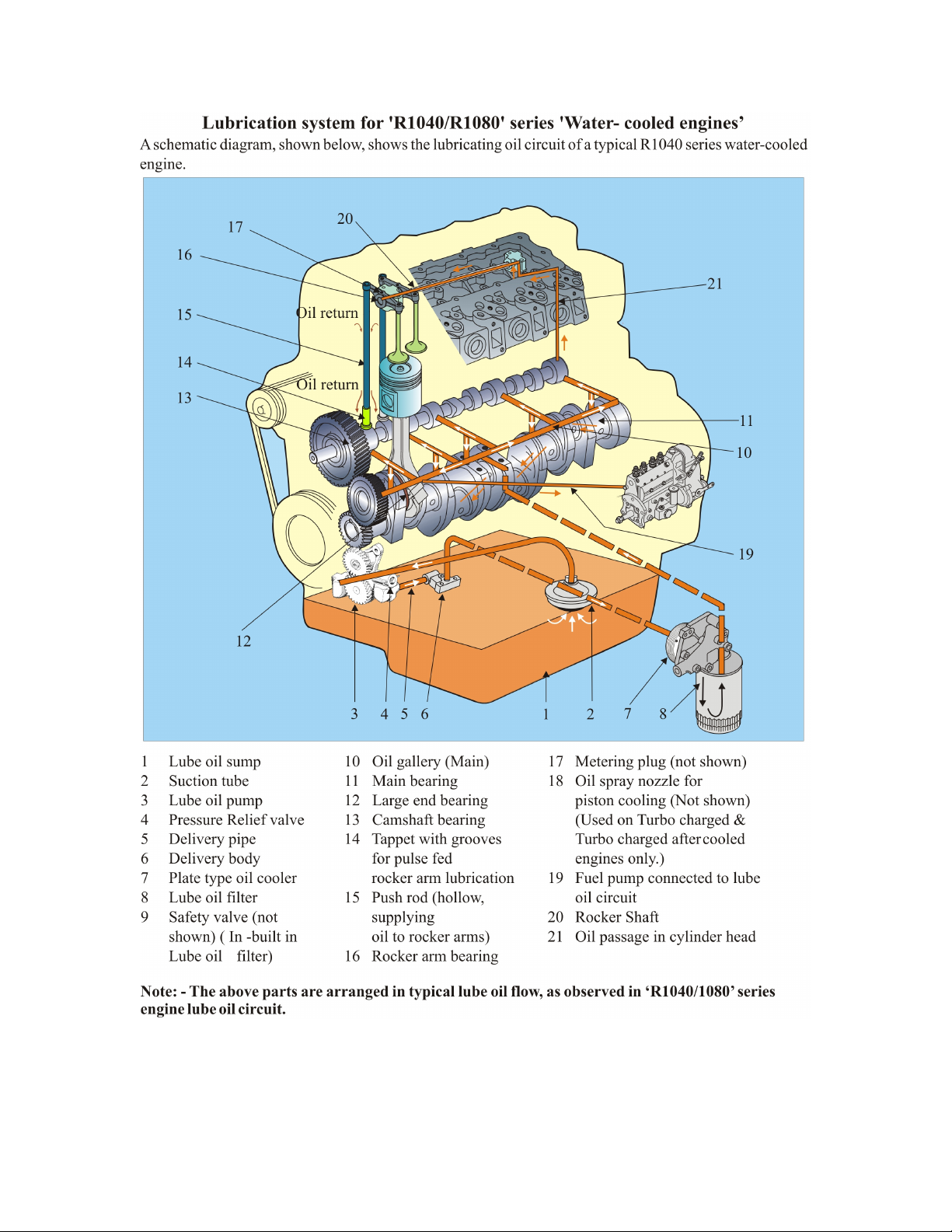

2.4.6 Lube oil Specifications and recommendations

The chart below shows the nomenclature of lube oil in different standards. Lube oils of

correct viscosity and detergency grades should be used. For detergency, oil should comply

with the following specifications

US Military

Specifications

American

Petroleum Institute

classification (API)

CCMC

MIL-2104C CD/SE -

MIL-2104C Plus

CF4 D4

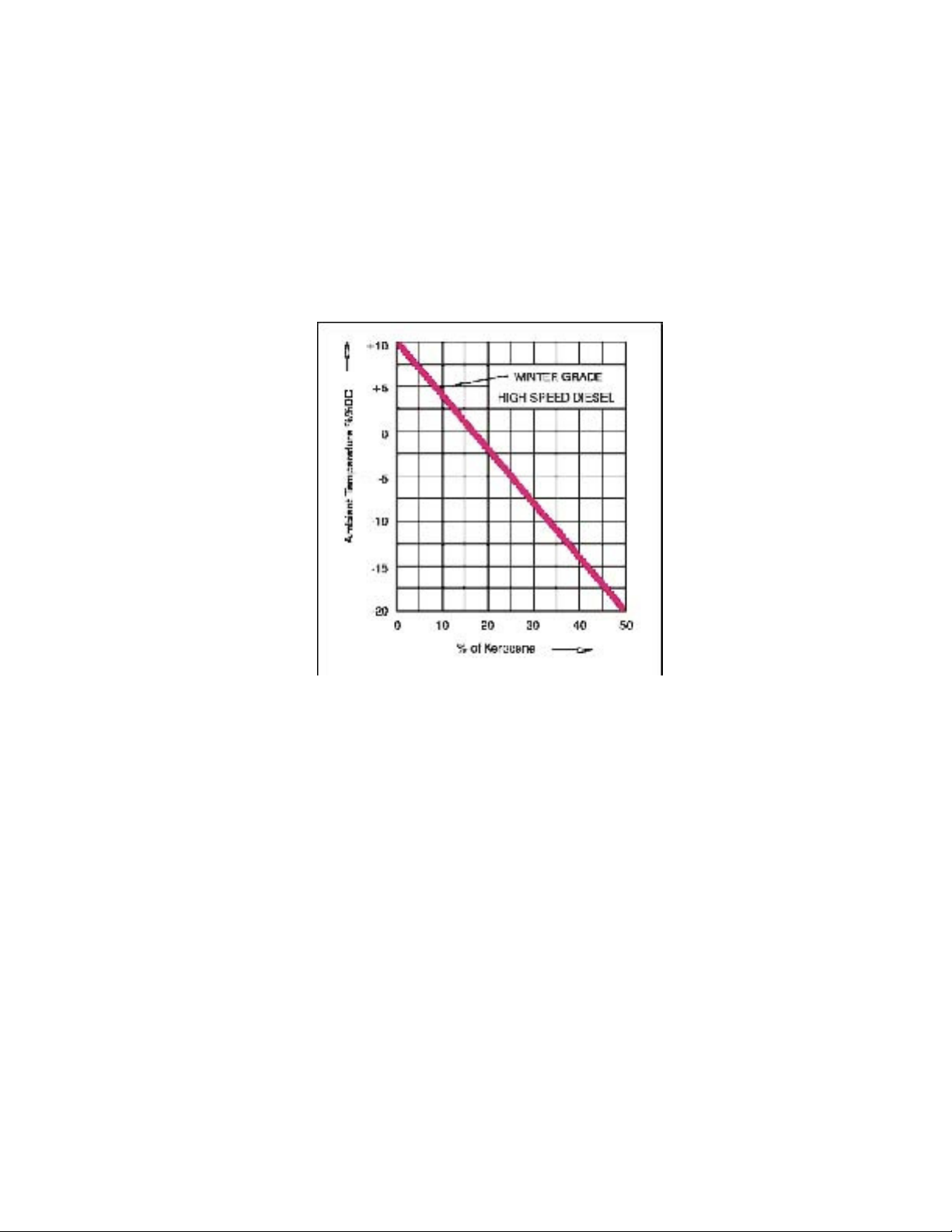

For viscosity, the recommended SAE number should be used. SAE J 30 specifies the viscosity of

Lube oils for each SAE No.

Always use oil brands of reputed oil companies. Too viscous oil causes starting difficulties. The

ambient temperature prevailing at the time of starting the engine should be governed the choice of the

viscosity grade, during winter operation.