9© 2023 | KISTERS

Maintenance

3 Maintenance

The maintenance of the OSS-B1 current meter can be divided in three sections as stated below. In addition, it is advisable that

the user maintain the OSS-B1 current meter at all time.

§

Keep the OSS-B1 case clean.

§

Clean all the tools after usage.

§

Use lint free paper towels and white spirit (do not use methylated).

§

Office service is required for the OSS-B1 current meter about once a month if it is used on a daily basis (i.e. Fully dismantle

shaft assembly, fan carrier and fan; Clean each item using hot soapy water and then rinse with white spirit).

§

Check the lead and new the ends connections.

§

If the current meter fails the spin test, refer to the mechanical fault-finding section for details.

§

Test lead, counter and reed switch (refer to electrical fault-finding section for details).

For more information, see the following subsection:

§

Service and Recalibration

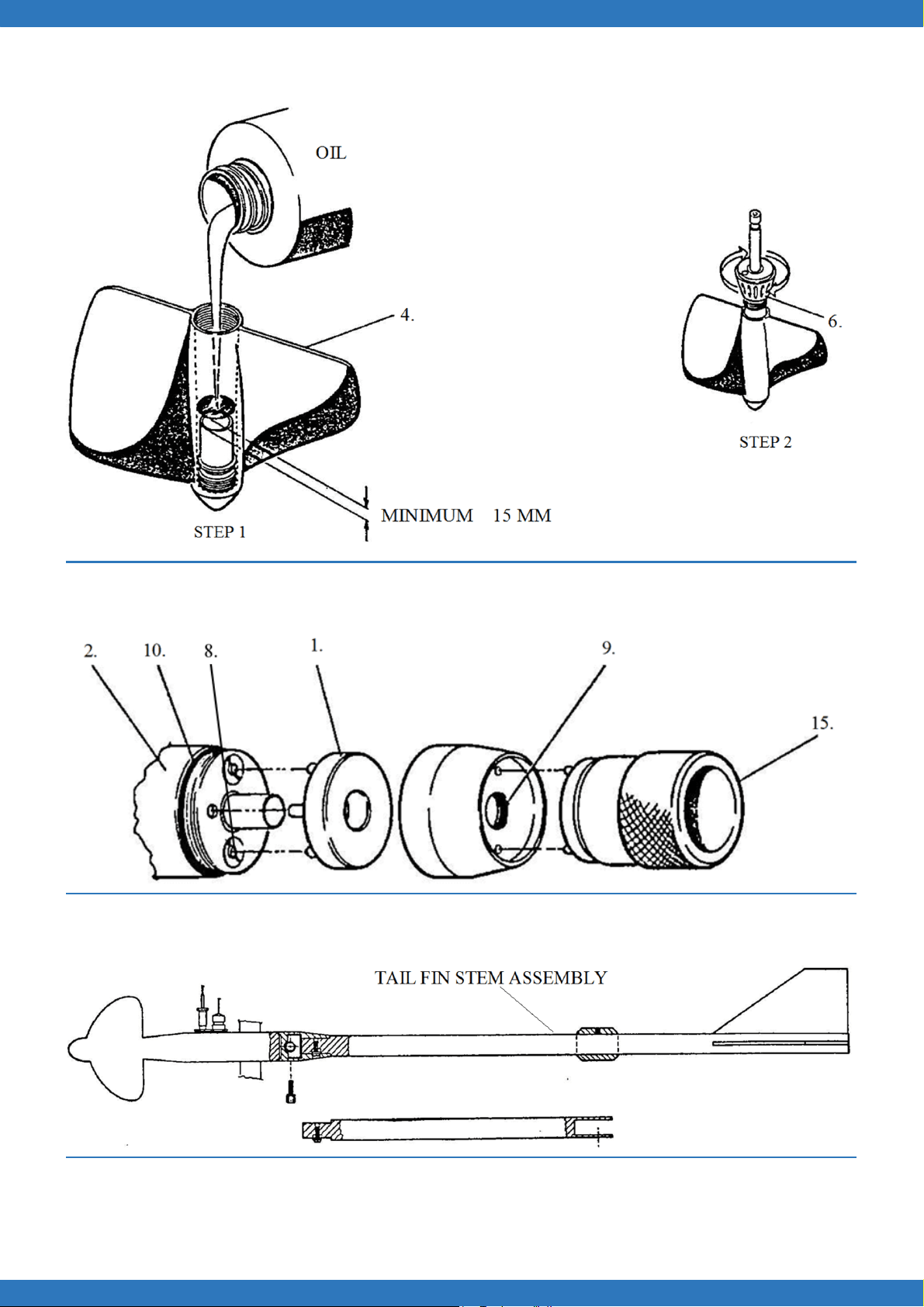

Section 1: Before commencing a discharge measurement, the following steps should be performed

§

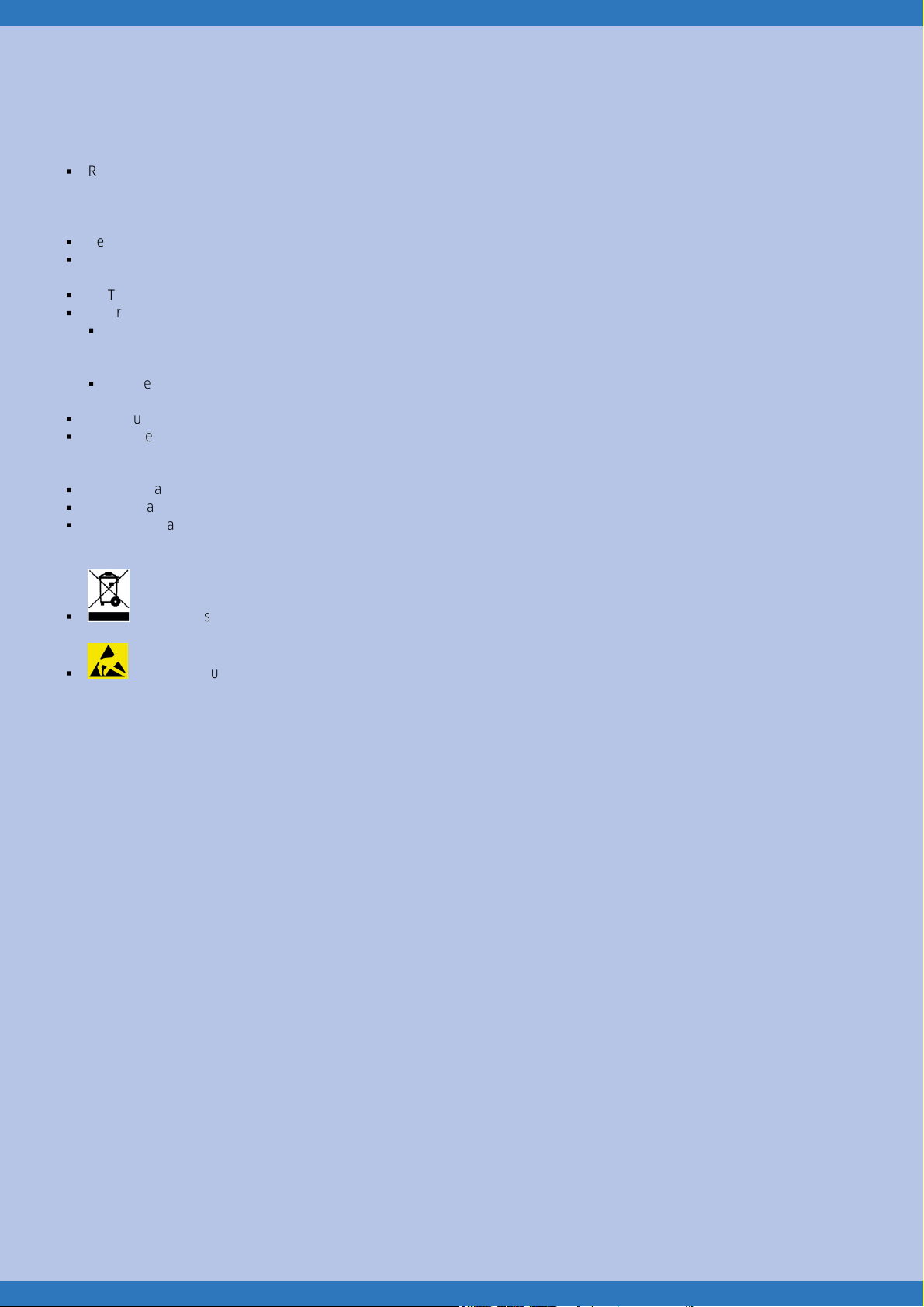

Remove shaft protector from spindle shaft using the provided flat blade screwdriver.

§

Remove fan carrier and shaft assembly from the fan by screwing anti-clockwise (ensure shaft assembly is placed on a

clean lint free cloth to prevent contamination of the bearings).

§

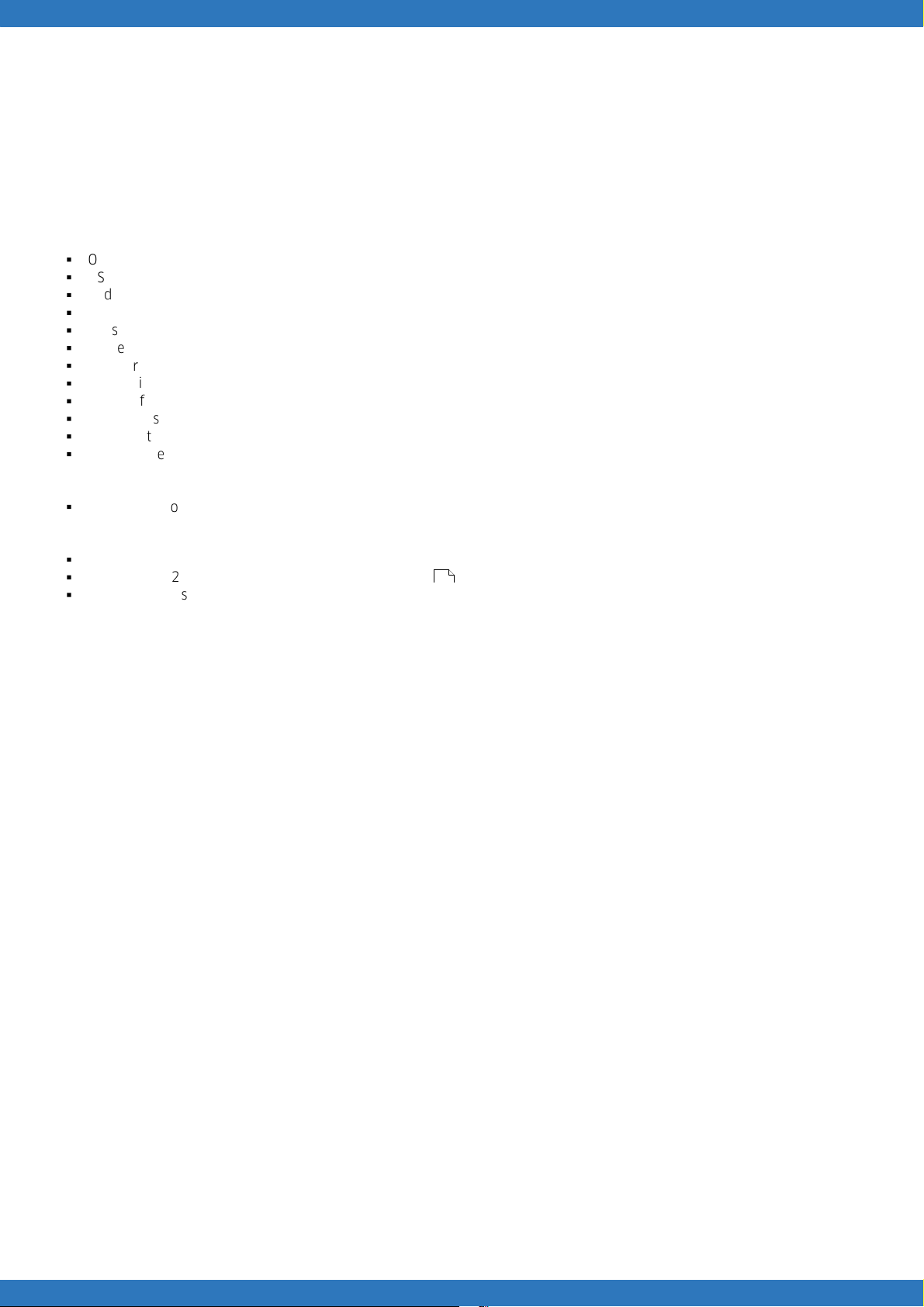

Fill the fan with fresh oil and screw the fan carrier assembly clockwise into the fan (hand tight only).

§

Re-assemble the fan carrier assembly onto the body and secure with the retraining screw.

§

Perform spin test.

§

Start gauging.

Section 2: During a gauging

After every one hour of use, the current meter should be cleaned before continuing a discharge measurement.

Before cleaning the current meter, perform a spin test to ensure the current meter has performed as expected during the last

measurement.

To clean the current meter, perform the following steps:

§

Remove the spare parts from the supplied cleaning jar and ¾ fill with white spirit.

§

Remove fan assembly from meter body by undoing the retraining screw and separating the body from the fan carrier

assembly.

§

Remove fan carrier and shaft assembly from the fan by screwing anti-clockwise (ensure shaft assembly is placed on a

clean lint-free cloth to prevent contamination).

§

Drain the old oil from the fan into a recycling container (for environmental reasons, do not pour white spirits on the

ground).

§

Put the bearing end of the spindle assembly into the cleaning jar and gently agitate.

§

Fill up the fan with white spirit and place your thumb over the threaded hole and shake vigorously for a few seconds.

§

Pour the white spirits into a recycling container (for environmental reasons, do not pour white spirits on the ground).

§

Remove the fan spindle assembly from the cleaning jar and blow dry.

§

Re-assemble the spindle assembly into the fan carrier.

§

Fill the fan with clean unused oil.

§

Screw the fan carrier assembly clockwise into the fan (hand tight only).

§

Re-assemble the fan carrier assembly onto the body and secure with the retraining screw.

§

Continue gauging.

Section 3: After the completion of gauging.

Before cleaning and storing the current meter, perform a spin test to ensure the current meter has performed as expected

during the last measurement.

To clean the current meter for storage, perform the following steps:

§

Remove the spare parts from the supplied cleaning jar and ¾ fill with white spirit.

§

Remove the fan assembly from the meter body by undoing the retraining screw and separating the body from the fan

carrier assembly.

§

Remove the fan carrier and the shaft assembly from the fan by screwing anti-clockwise (ensure shaft assembly is placed

on a clean lint-free cloth to prevent contamination).

§

Drain the old oil from the fan in a recycling container (for environmental reasons, do not pour white spirits on the ground).

§

Put the bearing end of the spindle assembly into the cleaning jar and gently agitate.

11

11

10