Always tighten the bolts at the specified torque. If the torque is

insufficient or excessive, the bolt will break, which is dangerous as the

chuck or work will fly out. Use the bolts attached to the chuck, and do not

use bolts other than these.

・If the torque is insufficient or

excessive, the bolt will break, which

is dangerous as the chuck or work

will fly out.

・Fix the lathe spindle or the chuck

when you tighten bolts. Your hand

could slip and get injury when you

work without fixing the spindle.

・You cannot control the torque by a

hex key. You must use a torque

wrench for torque control.

・Tighteningtorqueismomentofforcewhenyoutightenabolt.Tighteningtorque=F×L.

Provide sufficient strength for the draw pipe.

Provide sufficient screw depth for the draw pipe.

Firmly tighten the draw pipe.

・If the draw pipe break, the gripping force is instantly lost and this is dangerous as work

will fly out.

・If the screw depth of the draw pipe is insufficient, the screw will break and the gripping

force will be lost instantly, and this is dangerous as work will fly out.

・If the engagement of the screw of the draw pipe is loose, vibration may occur resulting

in breakage of the screw. If the screw breaks, the gripping force will be lost instantly,

which is dangerous as the work will fly out.

・If the draw pipe is unbalanced, vibration occurs, the screw is broken and the gripping

force will be lost instantly, which is dangerous as the work will fly out.

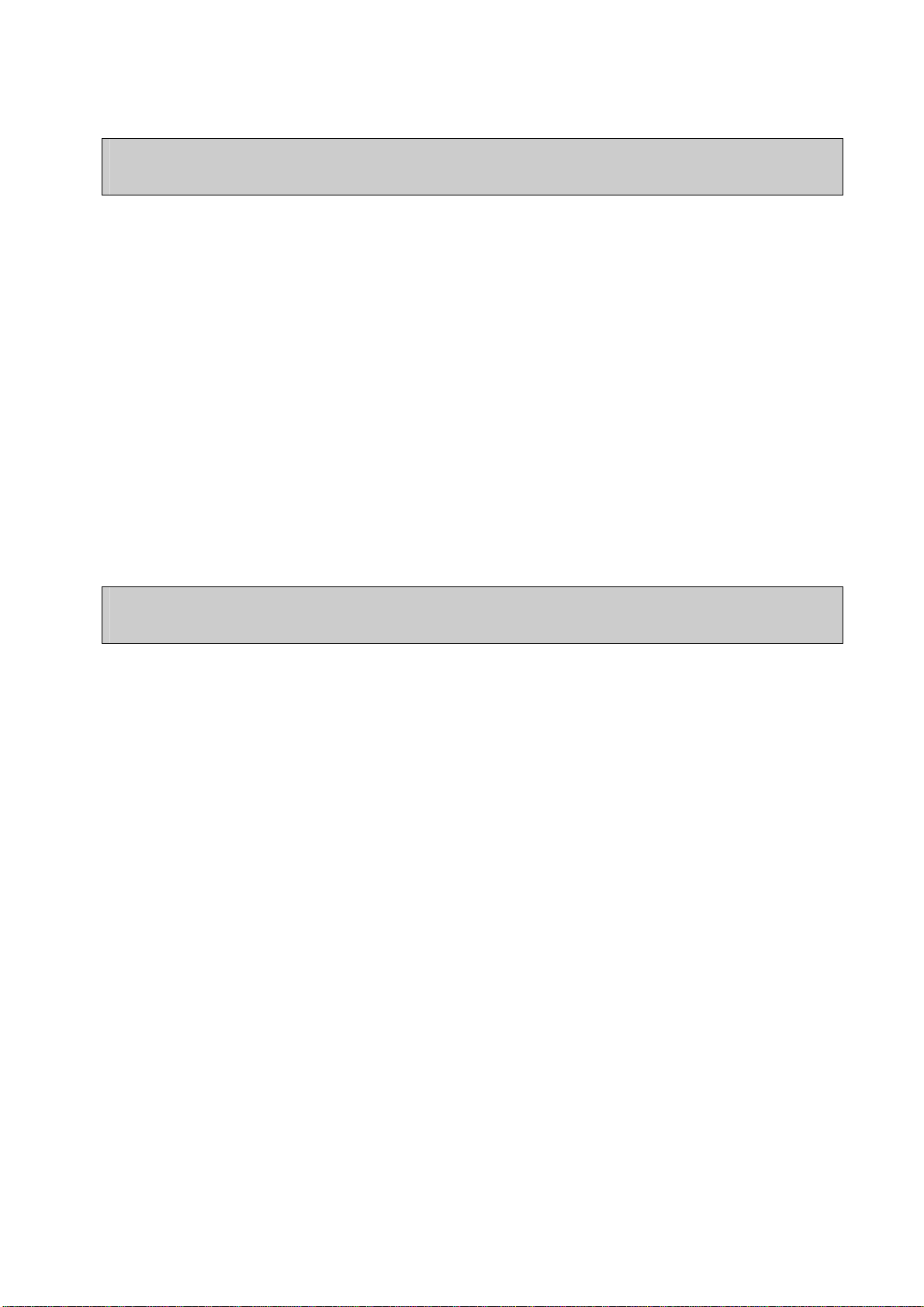

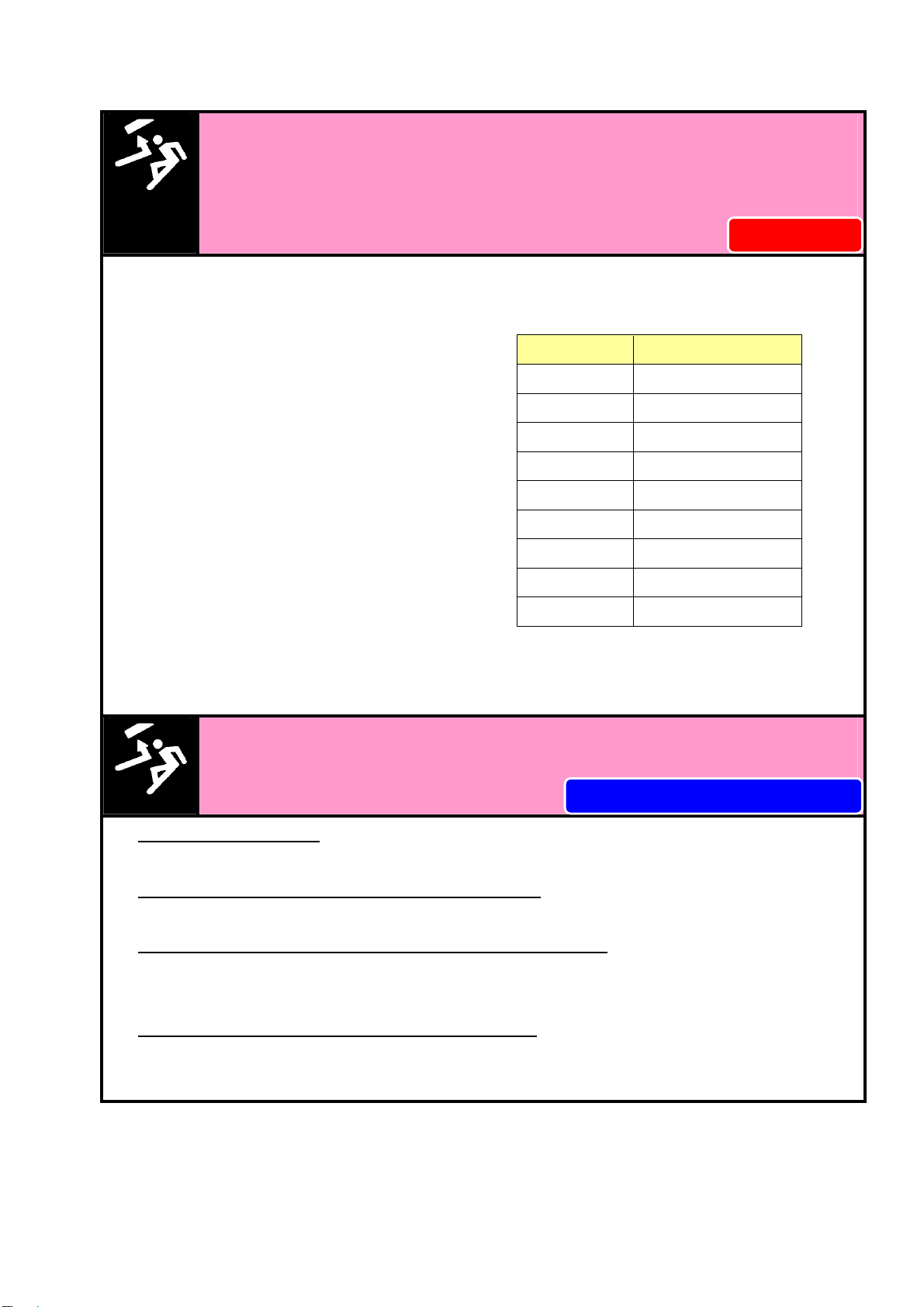

Specified torque for

socket head cap screw

Bolt size Tightening torque

M4 3.8 N・m

M5 7.5 N・m

M6 13 N・m

M8 33 N・m

M10 73 N・m

M12 107 N・m

M14 171 N・m

M16 250 N・m

M20 402 N・m

For Machine Tool Manufactures

For All Users