KITO TWER2 Installation manual

OM No.TWER 2-0903-MG-01

Introduction

KITO Twin Hook Electric Chain Hoist is intended to make accurate and safe parallel operation with the single motor and twin

hooks, which is best suited to applications where a long object or even lifting is required by using two lifting points.

Safety Precautions

Disassembly, assembly, repair, and adjustment of the electric chain hoist should be performed•

only by maintenance personnel.

Failure to follow this precaution may cause serious accidents leading to serious or even fatal injury.

DANGER

PROHIBITED

ER2 Twin Hook Electric Chain Hoist

(250kg to 5t)

Operation Manual

(TWER2/TWER2M/TWER2SP/TWER2SG)

COMPULSORY

This operation manual describes specific information regarding the Twin Hook Electric Chain•

Hoist. Before use, read and comply with both the ER2 Series Electric Chain Hoist (250kg to 5t)

Owner's Manual (separate volume) and this manual.

Sufficiently lubricate the load chain and idle sheave.•

Failure to follow these precautions may cause serious accidents leading to serious or even fatal injury.

2

Product Specifications

This twin hook electric chain hoist is designed the same as a standard hoist. Please refer to the sections of "Product

Specifications" in "ER2 Series Electric Chain Hoist Owner's Manual" (separate volume).

3

Trolley Configurations & Name

■

TWER2M (Motorized Trolley)

TS2 Series

plane trolley

Suspender

Frame F

Chain guide

Balance weight

Connection board

Idle sheave

Span

Nut

Screw fitting

Bottom hook 2

Frame M

Cushion rubber or

chain spring

Stopper

(load side)

Bottom hook 1

MR2 Series

motorized trolley ER2 Series Electric

Chain Hoist

Steel bucket dedicated

for twin hook type

Suspender

Cushion rubber

Stopper

(no-load side)

■TWER2 (Hook suspension)

Frame F

Chain guide

Balance weight

Connection board

Idle sheave

Span

Nut

Screw fitting

Bottom hook 2

Cushion rubber or

chain spring

Stopper

(load side)

Bottom hook 1

Frame M

ER2 Series Electric

Chain Hoist

Steel bucket dedicated

for twin hook type

Top hook

Cushion rubber

Stopper

(no-load side)

4

Assembly

■Trolley Width Adjustment

The Twin Hook Electric Chain Hoist (TWER2M) was pre-adjusted at the time of shipment to the beam width of the

customer on site. Depending on installation and space conditions, when it needs to disassemble and assemble the

trolley upon rearrangement or maintenance of the trolly frame, please refer to the section of "Combination with the

Trolley" in the ER2 Series Electric Chain Hoist (250kg to 5t) Owner's Manual (separate volume).

■Adjusting the Height of Bottom Hook

Do not adjust the height of the bottom hook beyond the threaded range visible from the check•

hole.

Failure to follow this precaution may cause serious accidents leading to serious or even fatal injury.

DANGER

PROHIBITED

COMPULSORY

Fasten nuts with the specified torque.•

Replace with a new split pin and be sure to insert and bend it.•

Failure to follow these precautions may cause serious accidents leading to serious or even fatal injury.

CAUTION

After installation, adjust the height of the bottom hook under no load.•

Failure to follow this precaution may cause serious injury or property damage.

COMPULSORY

Load chain

Chain pin

Screw fitting

Nut

Spring washer

Check hole

Connection fixture

●Single-chain Type

1) Measure the difference between heights of bottom hook 1 and

bottom hook 2 with the load suspended.

2) Remove the load and then loosen the nut.

3) Turn the screw fitting to adjust the height of the hook (within

the threaded range visible from the check hole).

4) Fasten the nut to fix the screw fitting (Torque: M16 - 164Nm,

M20 - 329Nm, M24 - 570Nm).

Chain pin

Load chain Screw fitting

Nut

Spring washer

Check hole

Connection fixture

●Double-chain Type

1) Measure the difference between heights of bottom hook 1 and

bottom hook 2 with the load suspended.

2) Remove the load and the chain pin.

3) Loosen the nut and then adjust the screw fitting by a length

twice the measured within the threaded range visible from the

check hole.

4) Fasten the nut to fix the screw fitting (Torque: M16 - 164Nm,

M20 - 329Nm, M24 - 570Nm).

5) Make sure that the load chain is not twisted. Insert the chain

pin so that its head is oriented as shown in the left picture,

and insert a new split pin to fix it.

5

■Attaching Load Chain Accessories

The load chain is provided with a chain spring, a cushion rubber, a stopper, and a chain fixing plate in place. The

variations and installation of these parts differ from each capacity.

When replacing any of these parts or the load chain, attach properly them as follows.

●Chain Accessories Variatoins

The accessories are installed at the specific place as shown in the following table with reference to the figures on

Page 3 for single chain fall and on this page for double chain fall.

Rated load

250kg(125kg+125kg)

490kg(245kg+245kg)

500kg(250kg+250kg)

1t (500kg+500kg) 2t (1t+1t)

2.8t(1.4t+1.4t)

3t(1.5t+1.5t)

*3.2t(1.6t+1.6t)

4.8t(2.4t+2.4t)

5t(2.5t+2.5t)

Chain fall Single-chain type (single chain fall) Double-chain type (double chain fall)

Load side

Accessory Stopper

Cushion rubber

Stopper

Cushion rubber

Stopper

Chain spring

Limit stopper

Stopper

Chain spring (2 types x 2)

Limit stopper (2)

Stopper

Chain spring (2 types x 2)

Limit stopper (2)

Attached

position 5th link 6th link 5th link 6th link 5th link

No-load

side

Accessory Stopper

Cushion rubber

Stopper

Cushion rubber

Stopper

Cushion rubber

Stopper

Cushion rubber

Stopper

Cushion rubber

Attached

position 3rd link 3rd link 3rd link 3rd link 3rd link

*It is for Europe.

Double-chain type (double chain fall)

Stopper

Limit stopper

Chain spring (long)

Chain spring (short)

Cushion rubber

Stopper

Attachment of a stopper

6

Installation

For installation of the Twin Hook Electric Chain Hoist, refer to "Installation" in the ER2 Series Electric Chain Hoist Owner's

Manual (separate volume). With reference to the trolley mount, mounting the trolley at the end of the beam is the best

method from the structural point of view.

Installation or uninstallation should be performed only by personnel who are professional or•

competent.

(Consult your dealer or KITO; otherwise make a request of professional or competent

personnel for installation.)

Failure to follow this precaution may cause serious injury or property damage.

DANGER

PROHIBITED

CAUTION

At the time of installation, make sure that the load chain properly engages with the idle sheave•

without being twisted or slack. In mounting the trolley onto the beam by extending the trolley

width, make sure that the trolley does not derail.

Failure to follow this precaution may cause serious injury or property damage.

COMPULSORY

Operations

This twin hook electric chain hoist is operated the same as a standard hoist. Please refer to the sections of "How to Use"

in "ER2 Series Electric Chain Hoist Owner's Manual" (separate volume).

Do not obliquely lift a load.•

Do not use the twin hooks whose heights are different.•

Do not lift a load only via the Bottom hook 2.•

Failure to follow these precautions may cause serious accidents leading to serious or even fatal injury.

DANGER

PROHIBITED

CAUTION

When lifting a load only via the Bottom hook 1, reduce the load to a half of the rated load or•

less.

Make sure that the twin hooks vertically rises in lifting a load.•

Use a hoist whose specifications (span) is suited for a load length.•

Failure to follow these precautions may cause serious injury or property damage.

COMPULSORY

7

Maintenance

■Daily Inspection and Periodic Inspection

Sufficiently lubricate the load chain and idle sheave.•

Before use, make sure that the limit switch properly works in lifting under no load.•

Failure to follow these precautions may cause serious accidents leading to serious or even fatal injury.

DANGER

COMPULSORY

CAUTION

Use properly the hoist in accordance with operational instructions as carrying out the daily•

and periodic inspections.

Periodically lubricate the needle bearing in the idle sheave by using the grease gun through•

two grease nipples.

Idle sheave

Outer ring

Thrust needle bearing

Inner ring

Grease nipple

Sheave shaft

Bearing

Fasten the bolts and screws with the proper torque.•

Failure to follow these precautions may cause serious injury or property damage.

COMPULSORY

In addition to the inspection items in the ER2 Series Electric Chain Hoist Owner's Manual (separate volume), please also

check the Twin Hook Electric Chain Hoist on the following items for the daily and periodic inspections. With reference to

"Criteria" of the inspection items in the ER2 Electric Chain Hoist (250kg to 5t) Owner's Manual, please turn to the points

for the same capacity as that (total capacity) of Twin Hook Electric Chain Hoist.

8

Twin Hook Electric Chain Hoist Inspection Items

Items

Inspection

period Inspection method Criteria When failed

Daily Periodic

Appearance

○ ○

- Visual check - There is no damage,

deformation, or remarkable

corrosion.

- The unit is not tilted (the

balance weight is attached).

Replace damaged parts.

Attach the balance weight.

Limit switch

○ ○

- Check the operation with no

load.

- Make sure that the hook stops

at the upper-limit and can be

lowered.

Contact your dealer.

Position of bottom

hook ○ ○ - Visual check - Even and accurate in position Adjust the height.

Bolts and nuts for

frame F/M ○ ○ - Visual check - There is no loose or dropped-

out bolt or nut.

Fasten securely.

Each hole of frame

F/M

○

- Measurement using a slide

caliper

- The amount of wear is 5% or

less (the difference between

vertical and horizontal

diameters of each hole is 5%

or less).

Replace damaged parts.

Chain guide ○- Visual check - There is no remarkable

damage, deformation, or wear.

Replace damaged parts.

Nut for screw fitting

○ ○

- Visual check - There is no loose or dropped-

out nut.

- The screw section can be

checked from the check hole.

Fasten securely.

Suspender

○

- Measure the hole diameter

using a slide caliper.

- The amount of wear is 5% or

less (the difference between

vertical and horizontal

diameters of each hole is 5%

or less).

Replace damaged parts.

Idle sheave

○ ○

- Visual check

- Daily inspection: Operation

with no load

- Periodic inspection: Operation

with a rated load

- Sufficiently lubricate.

- Smoothly rotating without

irregular sound.

Lubricate through the grease

nipple.

Replace damaged parts.

This manual suits for next models

3

Table of contents

Popular Other manuals by other brands

Curt Manufacturing

Curt Manufacturing C-2CL installation instructions

American Bath Factory

American Bath Factory Sistine Stone Neo Corner-Hnf installation guide

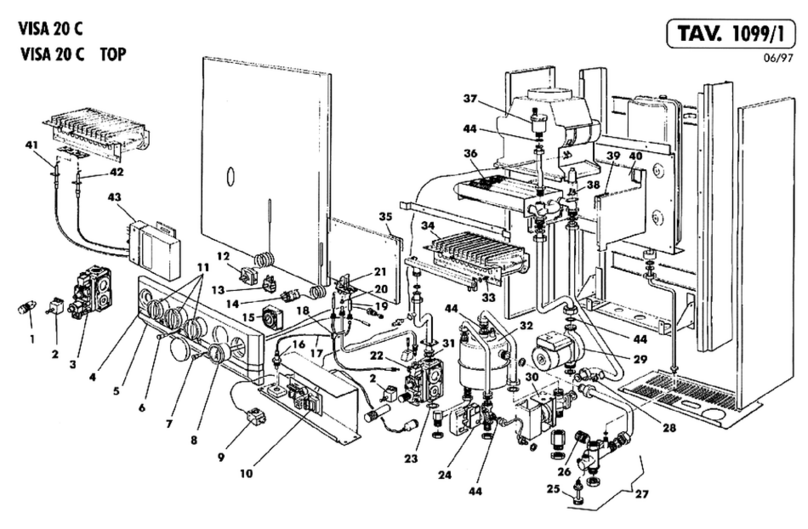

LAMBORGHINI

LAMBORGHINI VISA 20C - SCHEMA manual

IRO

IRO LUNA X3 operating instructions

Piaa

Piaa G3 LED Bulbs installation manual

Airaid

Airaid 450-331 installation instructions