KITO Harrington DHLT Manual

Dynamic Hoist Load Tester (DHLT)

Calibration Procedure

HARRINGTON HOISTS,INC.CONFIDENTIAL

1 of 4

General Use

EDOC0430

Rev. 01 10-5-2016

PURPOSE

To provide instructions for calibration of the DHLT.

SCOPE

(1) Includes the DHLT. Excludes the SHLT (Static Hoist Load Tester).

(2) Includes only calibration. Excludes setting the Pressure Switch and setting the Limit Switch.

(3) Calibration based on using Harrington 5T Electric Chain Hoist (either NER050L or ER050L).

INSTRUCTIONS

1. Collect Calibration Data

(a) Assemble 5 Ton Electric Chain Hoist and properly calibrated Force Measuring Device (Load

Cell or Dynamometer) to the 5 Ton link in the test stand (see Fig. 1).

(b) Connect power to test stand control panel.

(c) Connect pendant to test stand control panel.

(d) Connect cable between test stand control panel and hoist.

(e) Connect power to the hoist.

(f) Ensure the Accumulator Discharge Valve located between the accumulator and the reservoir

is closed (handle is perpendicular to the hoses).

(g) Press the On/Off pushbutton on the test stand control panel to turn on the DHLT. The DHLT

pump should begin operating and maintain system pressure between approx 1700-2300 psi.

For DHLT units shipped after 10/2010, the pump should begin operating and maintaining

system pressure between approx. 1700 – 2450 psi.

(h) Turn on the Dynamometer; assure that it is freely suspended from the Test Hoist with no

tension on it (other than the weight of the attached lower shackle). Press its zeroing button

and ensure the read-out indicates zero load.

Note: Do not press the zeroing button any time after testing starts.

(i) Use the Test Hoist to level the lower beam assembly; this minimizes any effects associated

with slant-lifting.

(j) Follow the calibration procedure for both the 5 ton and 10 ton links as follows. Using the

Pressure Control Valve (PCV), slowly adjust the cylinder pressure to increase the system

pressure. An increase of system pressure can be verified by the Cylinder Pressure Gauge

(CPG). See the last page of this document for a data recording chart.

Note: Small movements in the PCV correspond to large changes in the Dynamometer

reading, particularly on the 10 Ton link; avoid large or rapid adjustments to the PCV as

these can lead to pressure oscillations.

Note: During the following procedure, if you go above the target cylinder pressure while

adjusting “up”, reduce the cylinder pressure back down below the target value, and then

raise it up to the target value again. Similarly, if you go below the target cylinder

pressure while adjusting “down”, raise the cylinder pressure back above the target value,

and then lower it down to the target value again.

Dynamic Hoist Load Tester (DHLT)

Calibration Procedure

HARRINGTON HOISTS,INC.CONFIDENTIAL

2 of 4

General Use

EDOC0430

Rev. 01 10-5-2016

a. 5 Ton link:

i. Adjust cylinder pressure up to 200 psi and record dynamometer reading.

ii. Adjust cylinder pressure up from 200 psi to 1300 psi in 100 psi increments

recording the dynamometer reading at each increment.

iii. Adjust cylinder pressure just slightly above 1300 psi then back down to 1300 psi

and record dynamometer reading.

iv. Adjust cylinder pressure down from 1300 psi to 200 psi in 100 psi increments,

recording the dynamometer reading at each increment.

v. Average the two dynamometer readings for each cylinder pressure increment

recorded and record these results onto the DHLT Calibration Data Sheet.

vi. Adjust cylinder pressure to zero.

vii. Use the Test Hoist to lower the lower beam assembly to its fully lowered

position; this will remove the load from the Test Hoist.

viii. Remove the Test Hoist, dynamometer, and associated shackles from the DHLT’s

5 Ton link and attach them to the DHLT’s 10 Ton link.

b. 10 Ton Link

i. Repeat steps 1(h) and 1(i) above.

ii. Adjust cylinder pressure up to 200 psi and record dynamometer reading.

iii. Adjust cylinder pressure up from 200 psi to 700 psi in 100 psi increments,

recording the dynamometer reading at each increment.

iv. Adjust cylinder pressure just slightly above 700 psi, and back down to 700 psi,

and record dynamometer reading.

v. Adjust cylinder pressure down from 700 psi to 200 psi in 100 psi increments,

recording the dynamometer reading at each increment.

vi. Average the two dynamometer readings for each cylinder pressure increment

recorded, and record these results onto the DHLT Calibration Data Sheet.

vii. Use the Test Hoist to lower the lower beam assembly to its fully lowered

position; this will remove the load from the Test Hoist.

viii. Remove the Test Hoist, dynamometer, and associated shackles from the DHLT’s

10 Ton link.

2. Prepare Calibration Chart

(a) Enter the date and the DHLT serial number in the designated areas in the upper left-hand

area of the calibration spreadsheet (Request DHLT Cal rev00.xls from Harrington).

(b) Enter the “Average” values from the DHLT Calibration Data Sheet into the corresponding

yellow-colored cells of the calibration spreadsheet. This will cause the spreadsheet to (i)

generate two lines on the graph area of the spreadsheet, and (ii) enter values in the table

area (load vs. pressure) of the spreadsheet.

Dynamic Hoist Load Tester (DHLT)

Calibration Procedure

HARRINGTON HOISTS,INC.CONFIDENTIAL

3 of 4

General Use

EDOC0430

Rev. 01 10-5-2016

(c) Confirm that the two lines generated on the graph are linear, or close to linear (they will be

linear if their R2values are very close to 1). If not, investigate the cause, correct, and obtain

new test data. Recalibration may be required to obtain accurate values.

(d) Print the spreadsheet table (load vs. pressure) and attach it to the DHLT in a manner that is

visible to the operator.

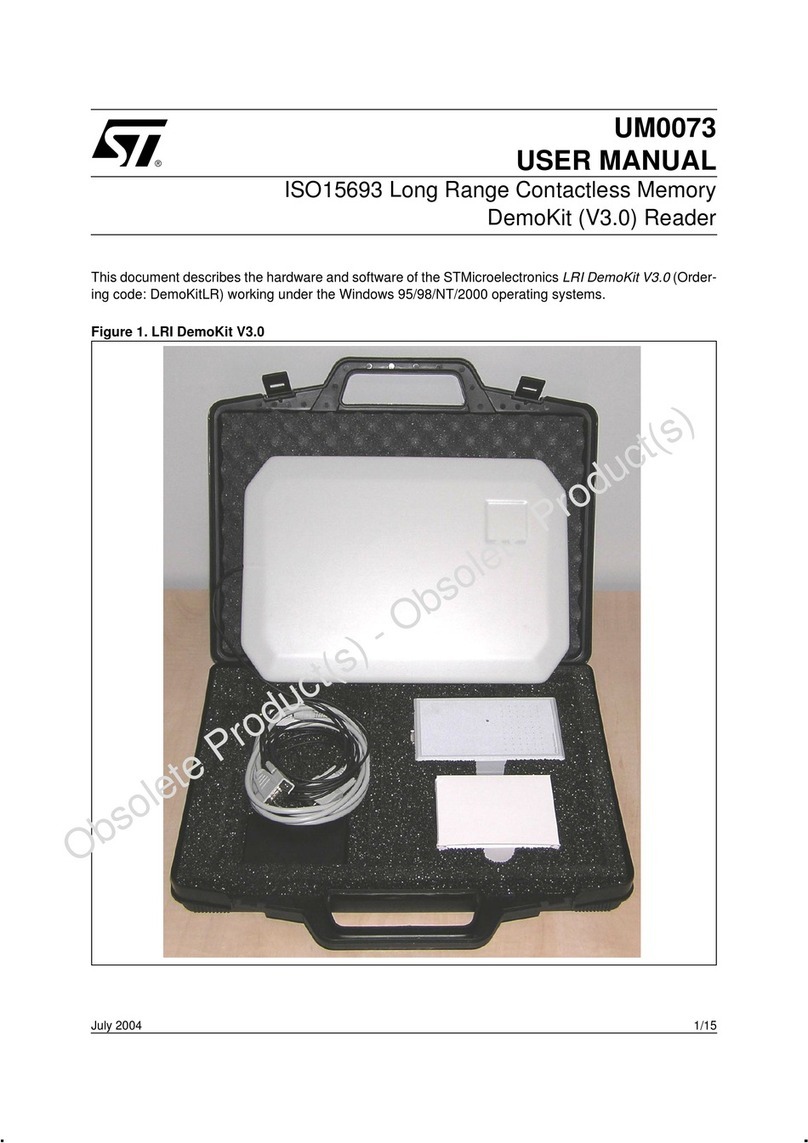

Figure 1

Dynamic Hoist Load Tester (DHLT)

Calibration Procedure

HARRINGTON HOISTS,INC.CONFIDENTIAL

4 of 4

General Use

EDOC0430

Rev. 01 10-5-2016

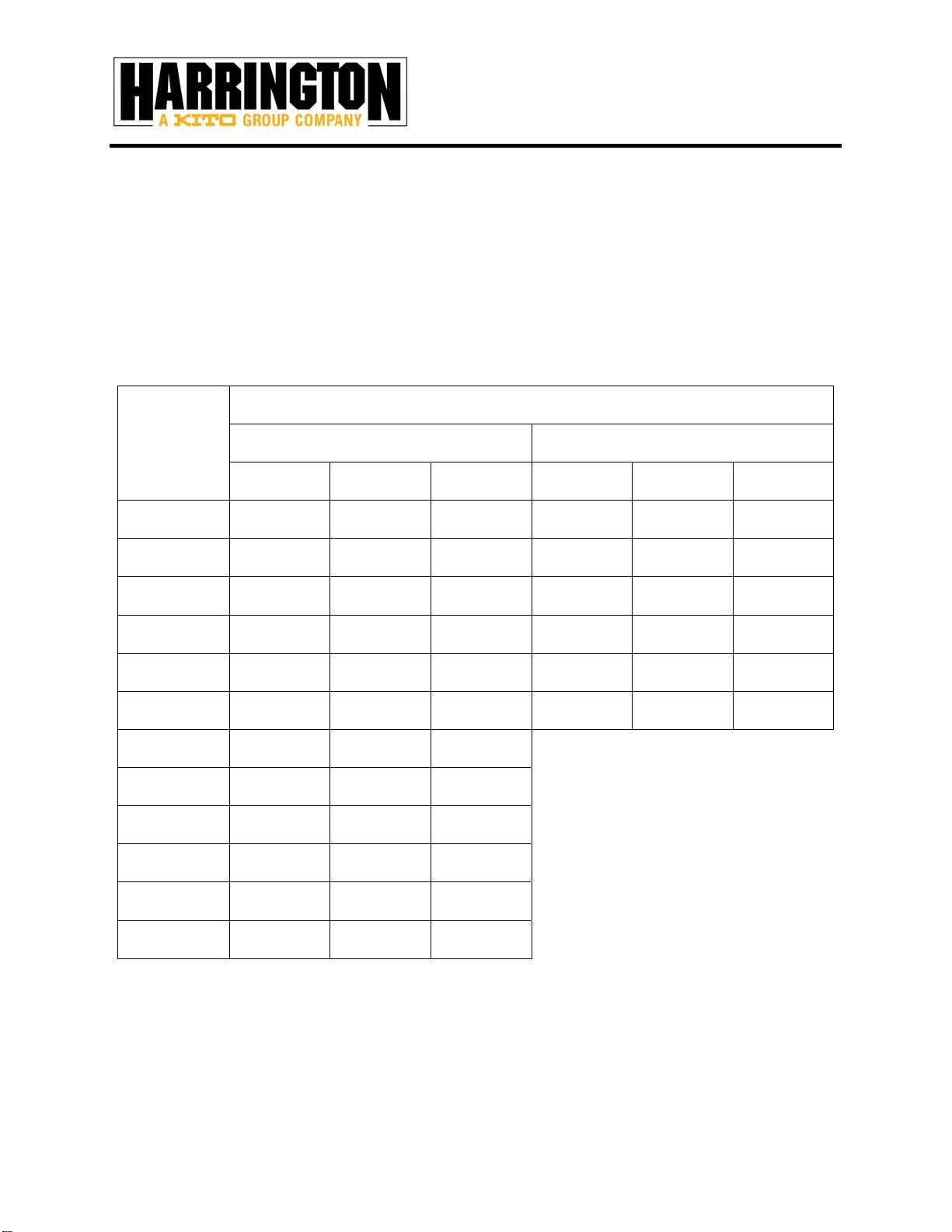

DHLT CALIBRATION DATA SHEET

Date: ____________________________

Serial Number: ______________________________

Cylinder

Pressure

(psi)

Force (lbs) Measured by Load Cell

5 Ton Link 10 Ton Link

Up Down Average Up Down Average

200

300

400

500

600

700

800

900

1,000

1,100

1,200

1,300

Table of contents