SPEEDGLIDER INSTALLATION MANUAL ii TM 2012-014 REV00 © 8/6/2012

Table of Contents

Notices: i

Documentation .......................................................................................................................................................i

Software Information ..............................................................................................................................................i

System Modifications..............................................................................................................................................i

Trademark and Patent Acknowledgments .............................................................................................................i

Contact Information................................................................................................................................................i

General Information 1

Introduction............................................................................................................................................................1

Warnings, Cautions, and Notes:............................................................................................................................1

Manual Hazards and Warning...............................................................................................................................1

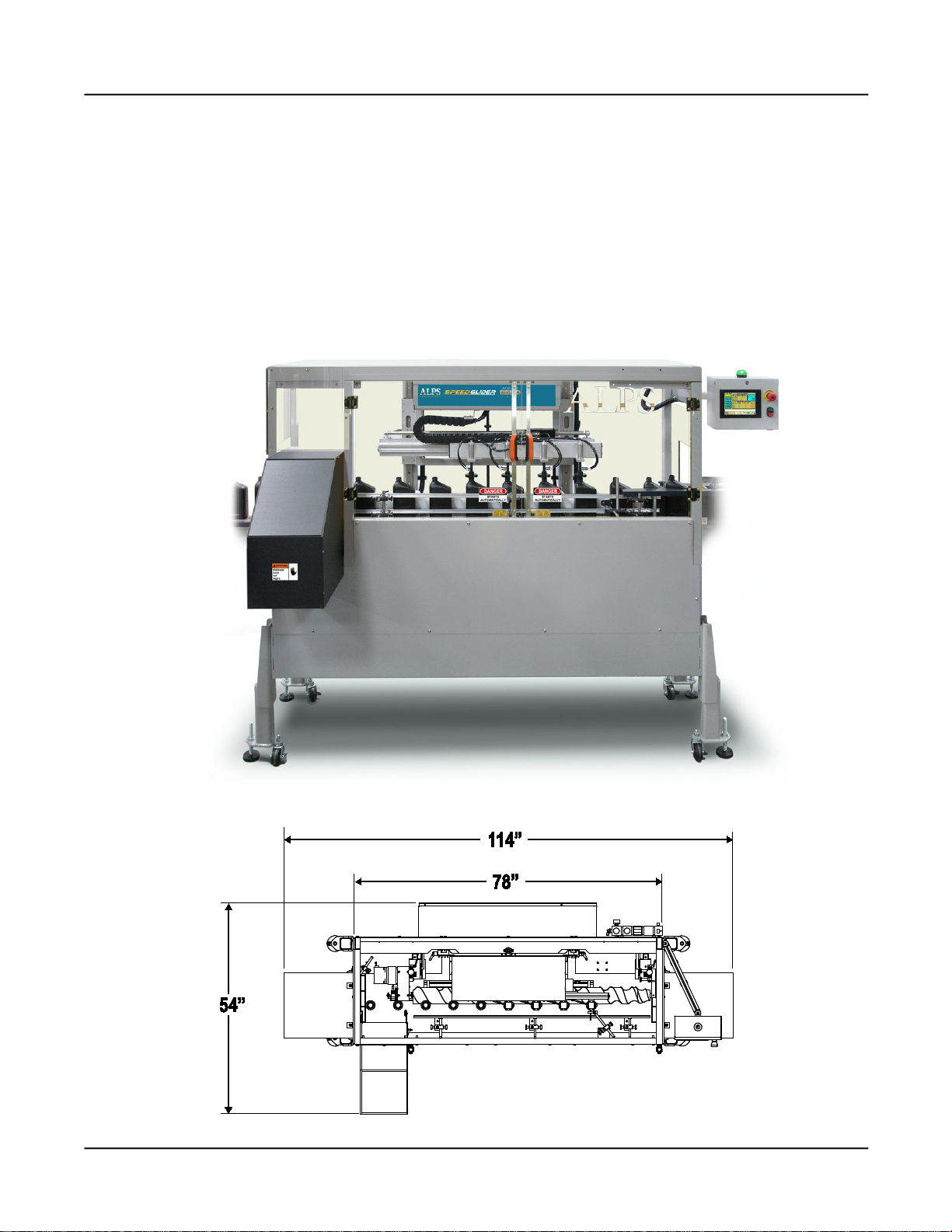

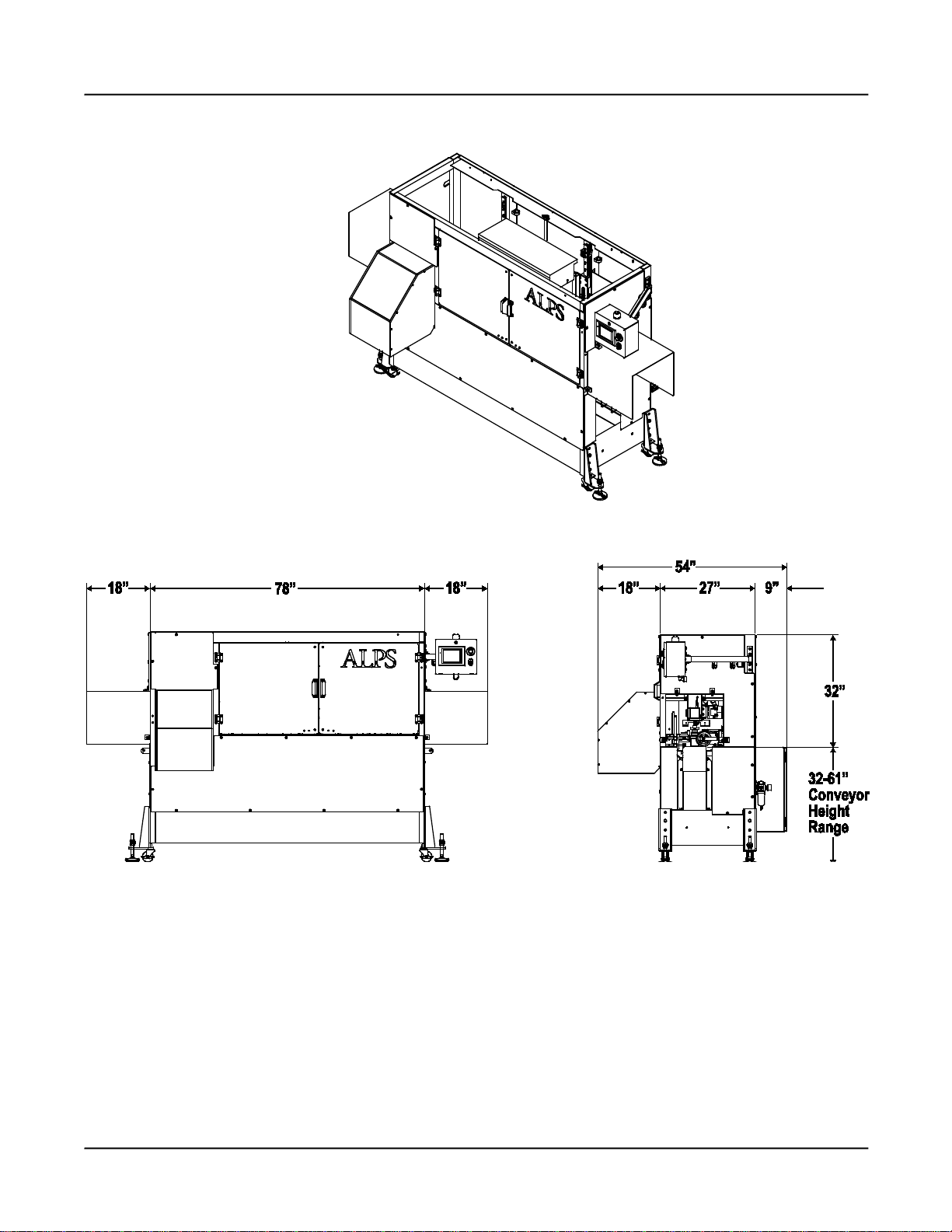

Linear Dimensions.................................................................................................................................................2

Section 1 Location, Installation, & Site Requirements3

Pneumatic Power Requirements: 120 PSI............................................................................................................3

Electrical Power Requirements: 110 VAC, 3Ø, 30A dedicated circuit..................................................................3

Air Supply: Minimum and Maximum air pressure..................................................................................................3

Section 2: Components Inventory 4

Common Components shipped with the SPEEDGLIDER.....................................................................................5

Section 3: Installation to Conveyor System 7

Hoist the SPEEDGLIDER machine from the pallet and install legs......................................................................7

Install Support Legs...............................................................................................................................................8

Transport the SPEEDGLIDER ..............................................................................................................................8

Installation to Conveyor System procedure ..........................................................................................................9

Front Panel Assembly .........................................................................................................................................11

Centering Probes over Conveyor........................................................................................................................13

Vertical Alignment to Conveyor...........................................................................................................................14

Leveling the machine ..........................................................................................................................................15

Install Rail Kit.......................................................................................................................................................19

Vertical Adjustment of Probe Carriage................................................................................................................20

Timing Screw Installation & Adjustment..............................................................................................................22