4

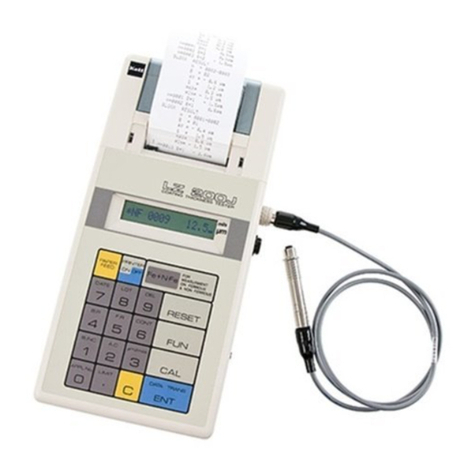

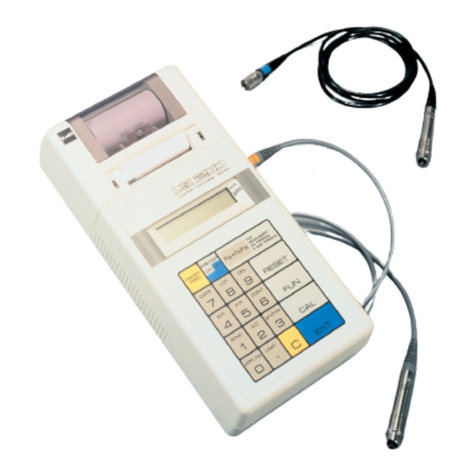

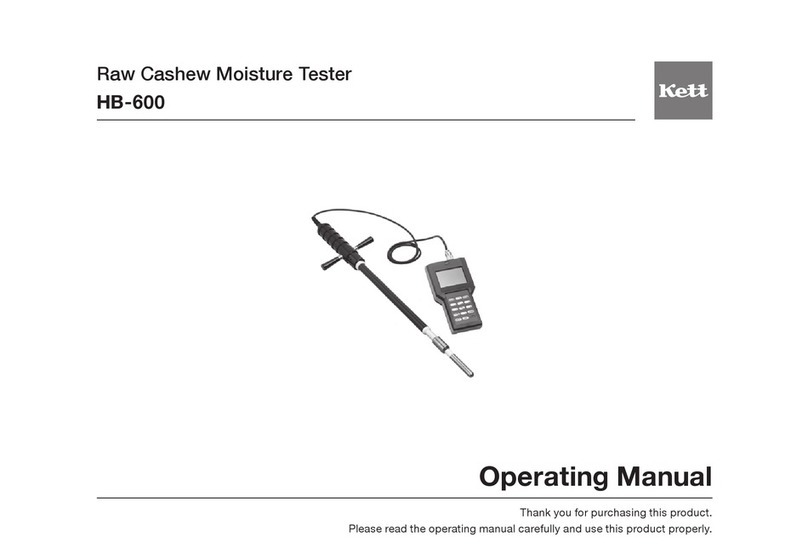

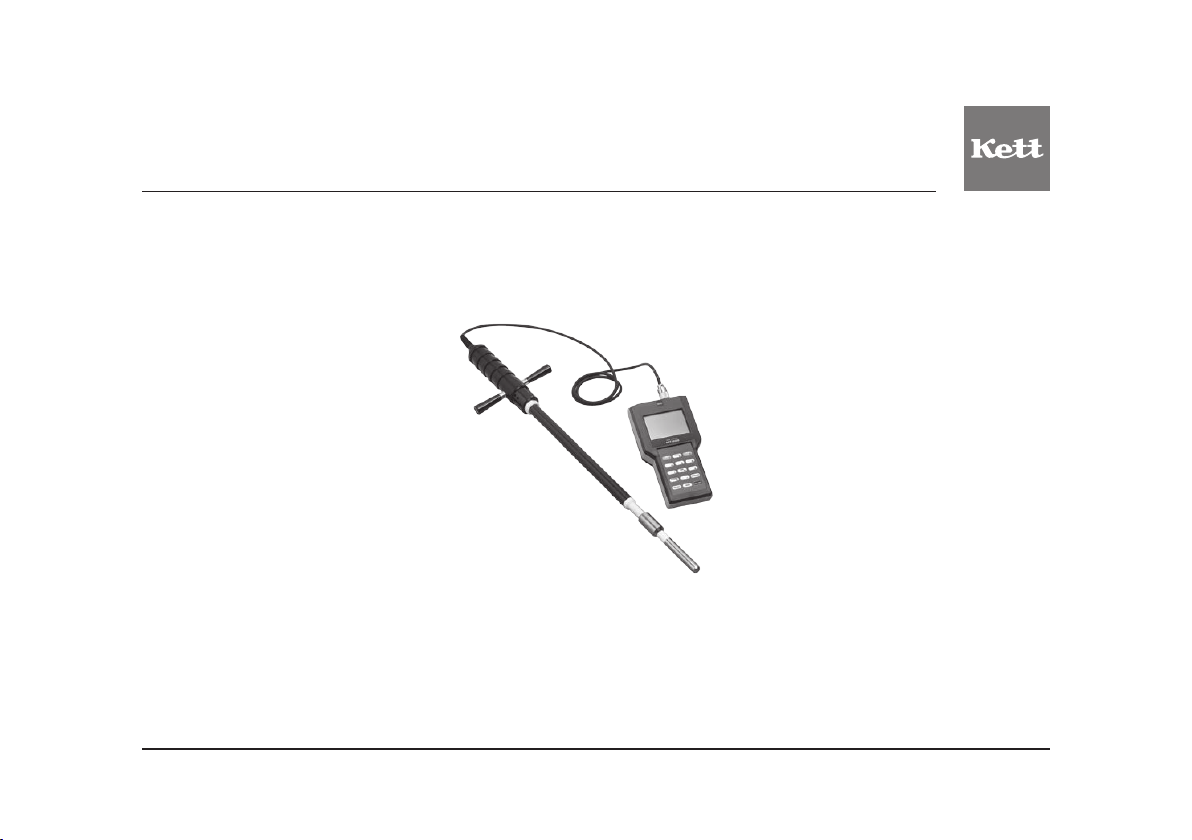

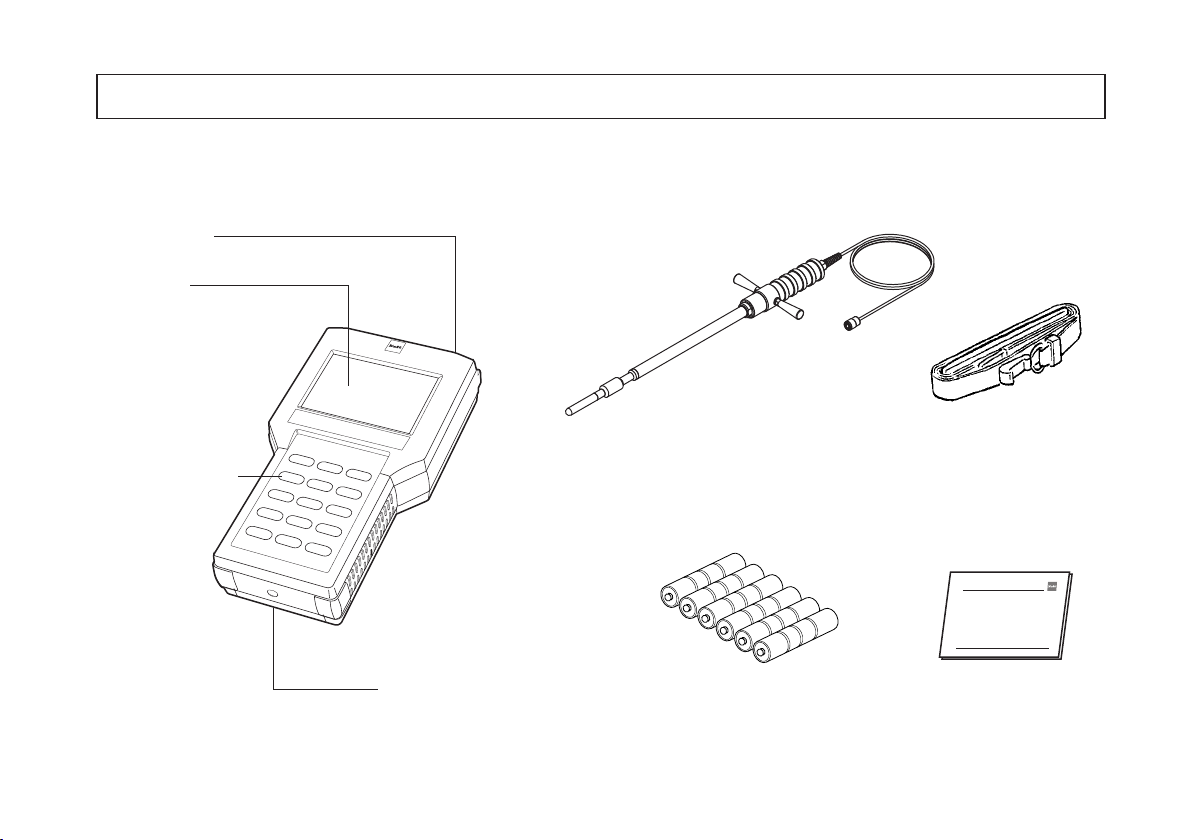

This unit is a wood chip moisture tester that applies electric resistance of an object to be measured. Only

putting the bar sensor into wood chips displays their moisture content (%). This moisture tester needs only

simple operation for quick measurement without selecting an operator or measurement environment.

1. Features

● Autopowerofunction

If no measurement is made or key is operated

for approximately 5 minutes, the power is

automatically shut off and avoids wasting the

batteries.

● Upperlimitsettingfunction

Setting any moisture value enables a buzzer to

sound when a measured moisture value exceeds

the set moisture value.

● Abletocompensateformoisturevalues

A moisture value can be corrected in the range

from -9.9 to +9.9%.

● Up to 13 types of user original calibration

curvesregistrable

In order to support various t ypes of wood

chips, user-originated calibration curves can be

registered under numbers from 03 to 15.

●Calibrationcurveselectablefrom2types

Regarding an electric resistance type moisture

tester, an electric resistance value of an object

to be measured is measured, and a moisture

content is converted from the resistance value.

This transformation formula is called a calibration

curve. This unit has pre-registered calibration

curves for cutting chips and crushing chips in

accordance with a dierence in shape and type

of wood chips, and accordingly, only selecting a

calibration curve number enables a user to simply

conduct measurement.

Calibration curve No. 02:

Crushing chips

Calibration curve No. 01:

Cutting chips