KITO HARRINGTON 3 Series User manual

END

TRUCKS

Top

Running &

Underhung

SERIES 3

1 Ton through 10 Ton Capacity

Model and Serial Number

EFFECTIVE: August 18, 2021

This equipment should not be installed, operated, or maintained by

any person who has not read and understood all the contents of this

manual. Failure to read and comply with the contents of this manual

can result in serious bodily injury or death, and/or property damage.

2

INSTALLATION, OPERATION, MAINTENANCE

AND PARTS MANUAL FOR SERIES 3 END

TRUCKS

Series 3 Top Running and Underhung End Trucks

Thank you for selecting Harrington’s Series 3 End Trucks for your material handling needs. We believe

the Series 3 End Truck will provide you years of trouble-free service when properly maintained. Further,

by applying the information in this manual, you will obtain dependable performance from our products.

The Harrington Series 3 End Truck was designed to operate either manually or with an electrical power

source. Therefore, it is important that you follow this manual to properly install and operate your Series 3

End Trucks. It is the owner’s and user’s responsibility to determine the suitability of a product for a

particular use. It is recommended that all applicable industry standards, federal, state, and local

regulations be checked concerning the installation, operation and maintenance of the Series 3 End

Trucks. Read all operating instructions and warnings before operation.

3

Table of Contents

Section Page Number

1.0 Important Information and Warnings………………………………………………………………………….5

1.1 Terms and Summary

1.2 Warning Tags and Labels

2.0 Technical Information…………………………………………………………………………………………..8

2.1 Specifications for Underhung End Trucks

2.2 Specifications for Top Running End Trucks

2.3 Component Names

2.4 Bridge Crane Design Requirements

3.0 Assembly, Installation and Test Trial Operation…………………………………………………………….24

3.1 Underhung End Trucks

3.2 Top Running End Trucks

3.3 Max-E-Lift End Trucks

3.4 Drive Shafts for Geared End Trucks

3.5 Crane Wiring

3.6 Power Source

3.7 Testing

4.0 Operation………………………………………………………………………………………………………36

5.0 Inspection……………………………………………………………………………………………………...37

5.1 General

5.2 Inspection Classification

5.3 Frequent Inspection

5.4 Periodic Inspection

5.5 Occasionally Used End Trucks

5.6 Inspection Records

5.7 Inspection Methods and Criteria

4

Section Page Number

6.0 Lubrication…………………………………………………………………………………………………….. 44

7.0 Maintenance & Handling……………………………………………………………………………………...45

7.1 General

7.2 Gear Motor -Reduction Gear

7.3 Gear Motor - Brake

7.4 Brake Adjustment

7.5 Storage

7.6 Outdoor Installations

8.0 Troubleshooting……………………………………………………………………………………………….49

9.0 Warranty……………………………………………………………………………………………………….52

10.0 Parts List……………………………………………………………………………………………………….53

5

1.0 Important Information and Warnings

1.1 Terms and Summary

This manual provides important information for personnel involved with the installation, operation and

maintenance of this product. Although you may be familiar with this or similar equipment, it is strongly

recommended that you read this manual before installing, operating, or maintaining the product.

Danger, Warning, Caution, and Notice

Throughout this manual, there are steps and procedures that can present hazardous situations. The following

signal words are used to identify the degree or level of hazard seriousness.

Danger indicates an imminently hazardous situation which, if not avoided, will result in

death or serious injury, and property damage.

Warning indicates an imminently hazardous situation which, if not avoided, could result in

death or serious injury, and property damage.

Caution indicates a potentially hazardous situation which, if not avoided, may result minor

or moderate injury or property damage.

Notice is used to notify people of installation, operation, or maintenance information which

is important but not directly hazard-related.

These general instructions deal with the normal installation, operation, and maintenance situations

encountered with the equipment described herein. The instructions should not be interpreted to

anticipate every possible contingency or to anticipate the final system, crane, or configuration that uses

this equipment. For systems using the equipment covered by this manual, the supplier and owner of the

system are responsible for the system's compliance with all applicable industry standards, and with all

applicable Federal, State, and Local regulations/codes.

This manual includes instructions and parts information for a variety of end truck types. Therefore, all

instructions and parts information may not apply to any one type or size of specific end truck. Disregard

those portions of the instructions that do not apply.

Record your end truck’s Model Type and Serial Number on the front cover of this manual for

identification and future reference to avoid referring to the wrong manual for information or instructions

on installation, operation, inspection, maintenance, or parts.

Use only Harrington authorized replacement parts in the service and maintenance of your Harrington

end trucks.

6

Equipment described herein is not designed for and MUST NOT be used for lifting, supporting, or

transporting people, or for lifting or supporting loads over people.

Equipment described herein should not be used in conjunction with other equipment unless necessary

and/or required safety devices applicable to the system, crane, or application are installed by the system

designer, system manufacturer, crane manufacturer, installer, or user.

Modifications to upgrade, rerate, or otherwise alter this equipment shall be authorized only by the original

equipment manufacturer.

Equipment described herein may be used in the design and manufacture of cranes or monorails. Additional

equipment or devices may be required for the crane and monorail to comply with applicable crane design

and safety standards. The crane designer, crane manufacturer, or user is responsible to furnish these

additional items for compliance. Refer to ANSI/ASME B30.16, Safety Standard for Overhead Hoists;

ANSI/ASME B30.2 Safety Standard for Top-Running Double-Girder Cranes; and ANSI/ASME B30.11 Safety

Standard for Underhung Cranes and Monorails.

If a below-the-hook lifting device or sling is used with a hoist, refer to ANSI/ASME B30.9, Safety Standard

for Slings, or ANSI/ASME B30.20, Safety Standard for Below-the-Hook Lifting Devices.

Hoists and cranes, used to handle hot molten material may require additional equipment or devices. Refer

to ANSI Z241.2, Safety Requirements for Melting and Pouring of Metals in the Metalcasting Industry.

Failure to read and comply with any one of the limitations noted herein can result in serious bodily injury or

death, and/or property damage.

HAZARDOUS ELECTRICAL POWER IS PRESENT IN THE END TRUCK MOTOR, IN THE SUPPLY OF

ELECTRICAL POWER TO THE END TRUCK MOTOR, AND IN THE CONNECTIONS BETWEEN

COMPONENTS.

Before performing ANY maintenance on the equipment, de-energize the electrical supply to the equipment,

and lock and tag the supply device in the de-energized position. Refer to ANSI Z244.1, “Personnel

Protection - Lockout/Tagout of Energy Sources.”

Only trained and competent personnel should inspect and repair this equipment.

7

It is the responsibility of the owner/user to install, inspect, test, maintain, and operate the equipment

covered by this manual in accordance with the applicable ANSI/ASME B30 volume(s) and OSHA

Regulations.

It is the responsibility of the owner/user to have all personnel that will install, inspect, test, maintain, and

operate the equipment covered by this manual read the contents of this manual and applicable portions of

ANSI/ASME B30 volume(s), and OSHA Regulations.

If the owner/user of the equipment covered by this manual requires additional information, or if any

information in the manual is not clear, contact Harrington or the distributor of the end truck. Do not install,

inspect, test, maintain, or operate this equipment unless this information is fully understood.

A regular schedule of inspection of the equipment in accordance with the requirements of ANSI/ASME

B30 volume(s) should be established and records maintained.

Responsibility for cranes using Harrington Series 3 End Trucks:

•For cranes where HARRINGTON fabricates the bridge, Harrington is responsible for

the design of the crane based on information supplied by the customer at the time of

order.

•For cranes where OTHERS fabricate the bridge, the customer or fabricator is

responsible for the design of the crane.

1.2 Warning Tags and Labels

The End Trucks covered by this owner's manual may be used as part of a lifting system such as a crane. It is the

responsibility of the supplier and the owner of such a lifting system to provide for and ensure that the lifting

system be equipped with warning labels in accordance with applicable industry standards.

1.3 Conformance Statement

In order to meet requirements of the Crane Manufacturers Association of America (CMAA), the National

Electric Code (NEC) and the American National Standards Institute (ANSI/ASME) Harrington components

include:

•Thermal motor protection for all motors.

•Rubber bumpers

•Rubber bumpers and drop stops for motorized trolley hoists.

•Hoists load tested to 125% of rated capacity.

•Drop stops for all end trucks

•Rail sweeps for all end trucks

•Recommended bridge beams comply with CMAA.

8

2.0 Technical Information

2.1 Specifications for Underhung End Trucks

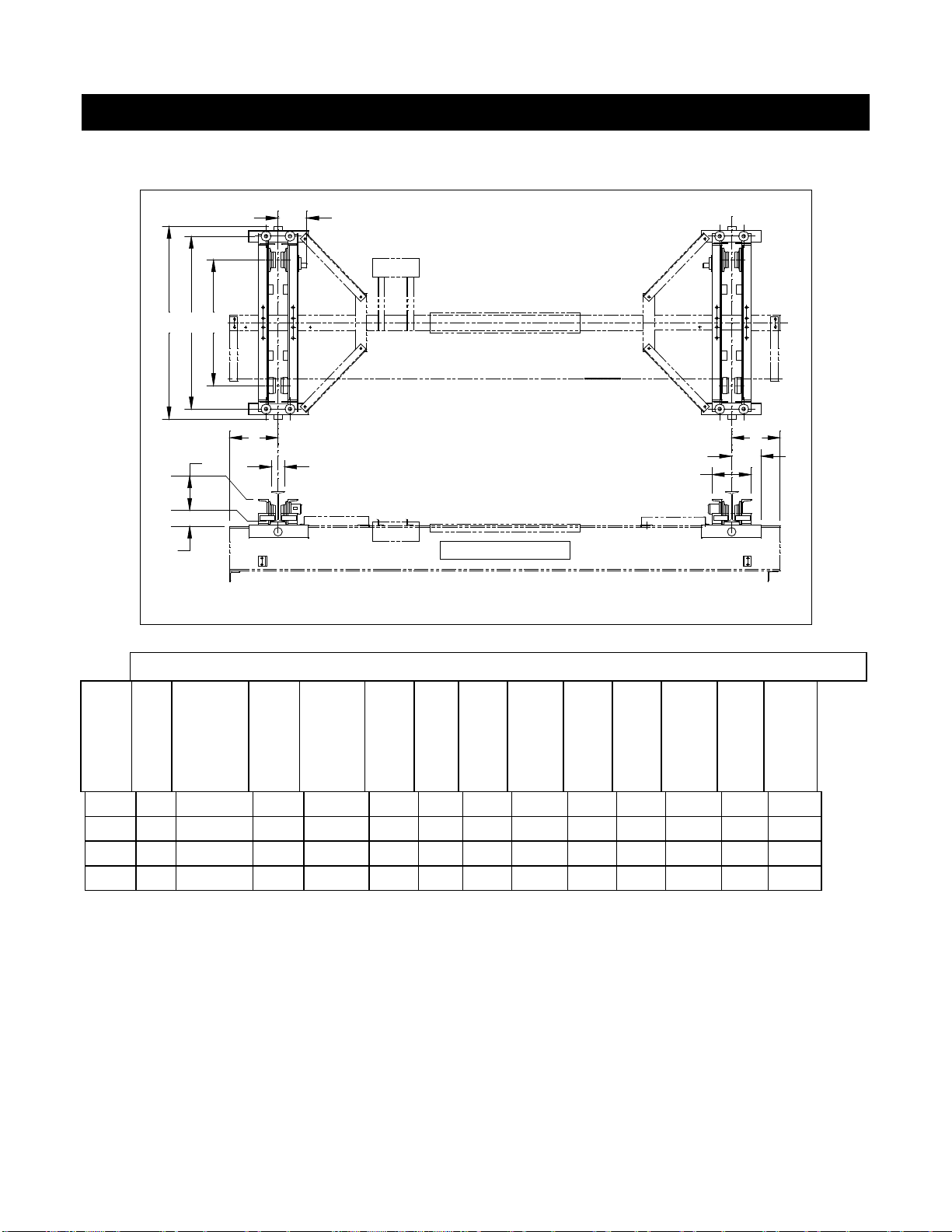

Harrington Hoists, Inc.

ABD

E

E

T

U

YMX

AA

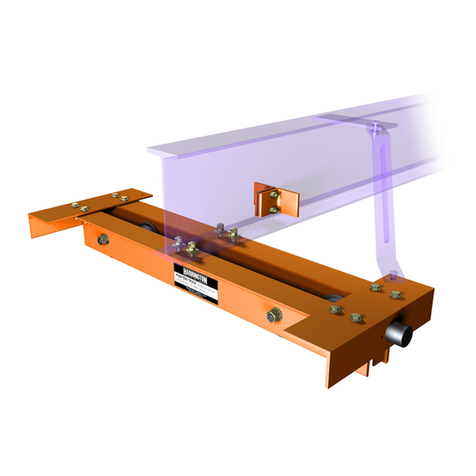

Figure 2-1 Underhung End Truck Dimensions

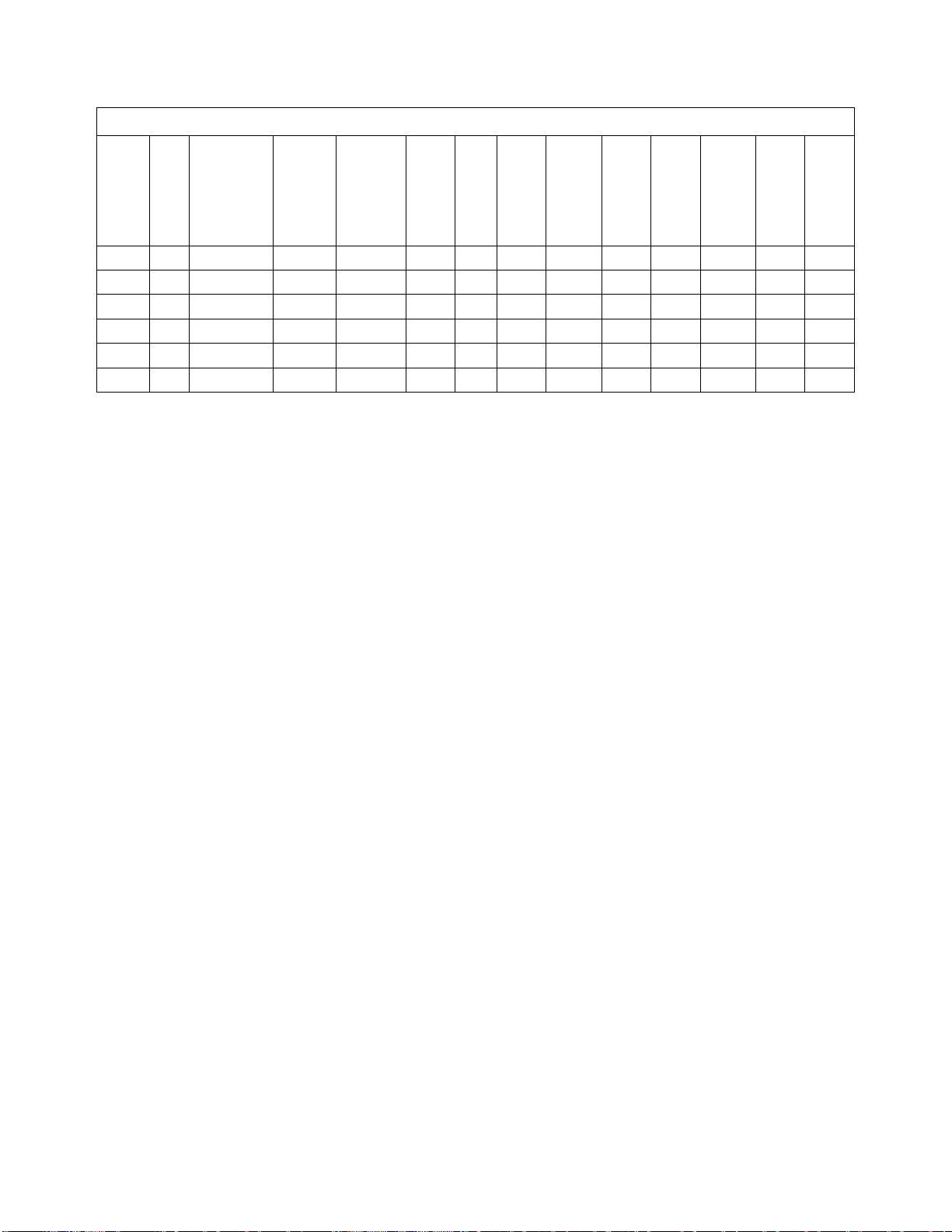

Underhung Push (Manual) End Trucks (Refer to Fig. 2-1)

Max.

Cap.

(Tons)

Max.

Span

(ft)

End Truck

Model # Wheel

Dia.

(in)

Flange

Range

Std. (in)

A

Overall

Length

(in)

B

Roller

Base

(in)

D

Wheel

Base

(in)

E *

Beam

Beyond

Span

(in)

M

End

Truck

Frame

Width

(in)

U

**

Wheel

Bottom

to

Beam

Top

(in)

X

Width

Beyond

Span

(in)

Y

Height

(in)

End

Truck

Weight

(lbs/pr)

2 35 UP-3-0235 4.33 3 - 6 60 53 39 12 T+8.1 1.8 11.3-T/2

6.5 448

2 45 UP-3-0245 4.33 3 - 6 82 75 61 12 T+8.1 1.8 11.3-T/2

6.5 585

3 35 UP-3-0335 4.92 3 - 6 60 53 35 12 T+8.2 1.9 11.3-T/2

6.5 472

5 35 UP-3-0535 5.51 4 - 6 60 53 33 12 T+9.8 2.0 11.3-T/2

6.4 546

* minimum overhang is M/2

** includes 3/8" thick beam mounting plates

9

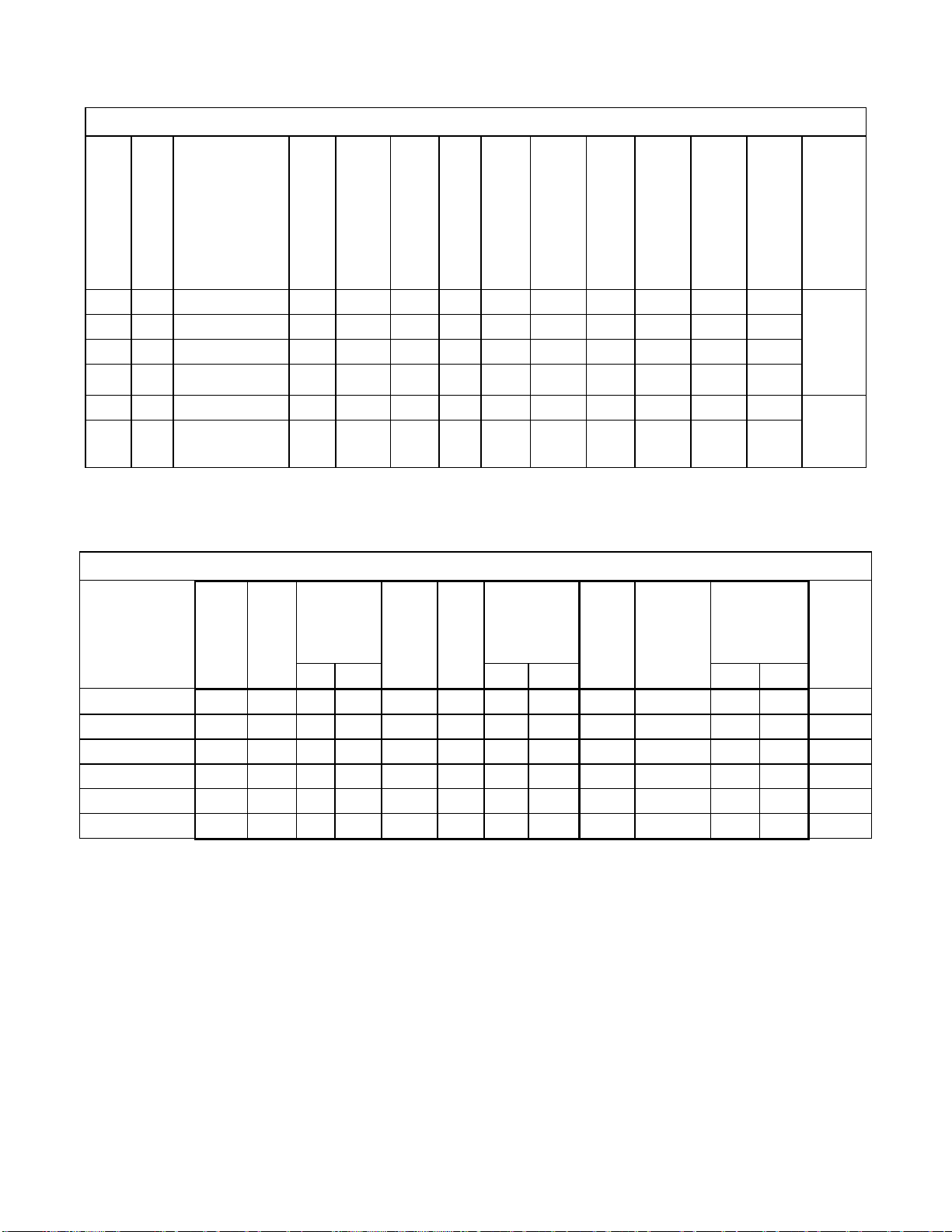

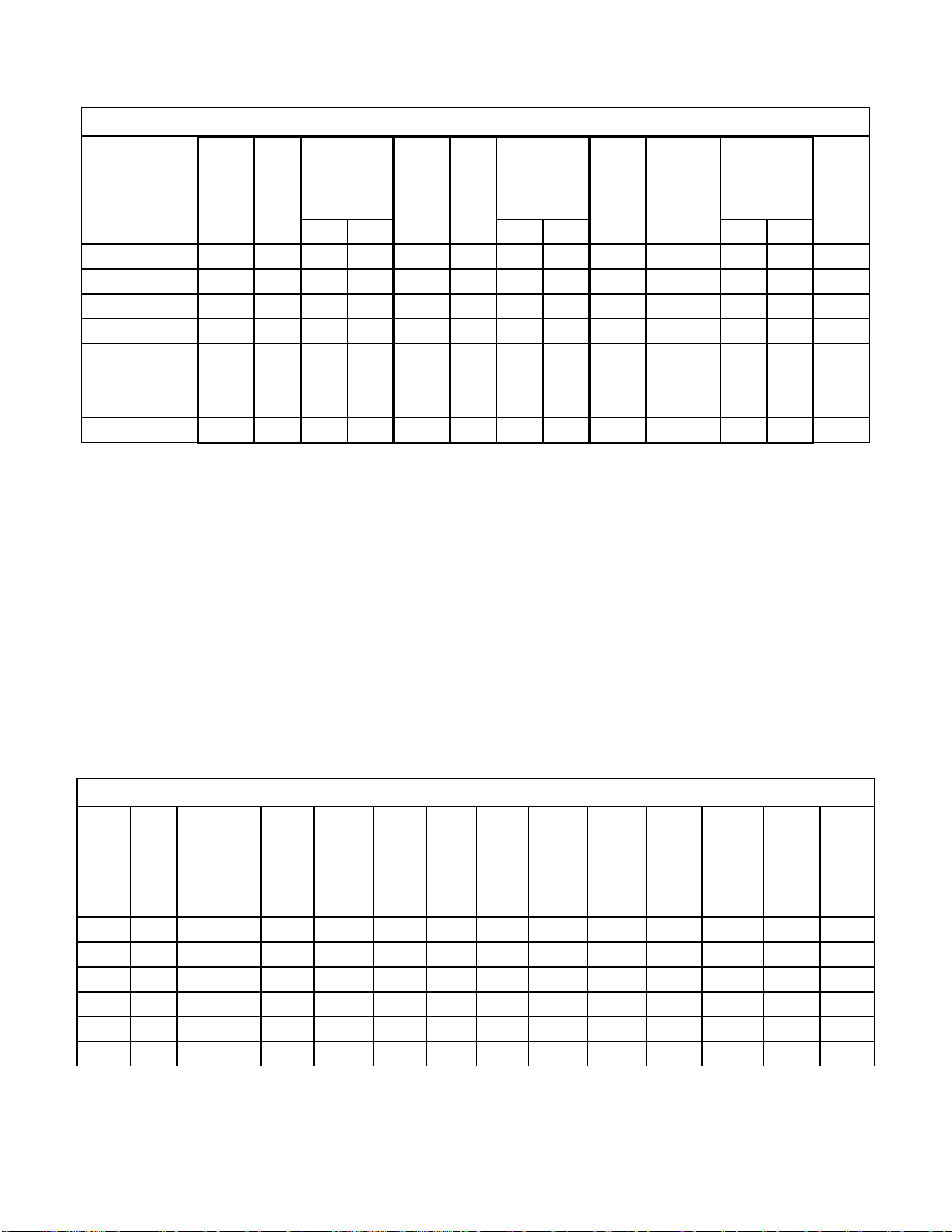

Underhung Geared End Trucks (Refer to Fig. 2-1)

Max.

Cap.

(Tons)

Max.

Span

(ft)

End Truck

Model # Wheel

Dia.

(in)

Flange

Range

Std. (in)

A

Overall

Length

(in)

B

Roller

Base

(in)

D

Wheel

Base

(in)

E *

Beam

Beyond

Span

(in)

J

Hand

Wheel

Offset

(in)

M

End

Truck

Frame

Width

(in)

U

**

Wheel

Bottom

to

Beam

Top

(in)

X Width

Beyond

Span (in)

Y

Wheel

Running

Surface

to

Upper

Most

Part of

ET

(in)

End

Truck

Weigh

t

(lbs/pr

)

2 35 UG-3-0235 4.33 3 - 6 60 53 39 12 T/2+9.0 T+8.1 1.8 11.3-T/2 6.5 503

2 45 UG-3-0245 4.33 3 - 6 82 75 61 12 T/2+9.0 T+8.1 1.8 11.3-T/2 6.5 640

3 35 UG-3-0335 4.92 3 - 6 60 53 35 12 T/2+8.9 T+8.2 1.9 11.3-T/2 6.7 529

3 45 UG-3-0345 4.92 3 - 6 82 75 57 12 T/2+8.9 T+8.2 1.9 11.3-T/2 6.7 666

5 35 UG-3-0535 5.51 4 - 6 60 53 33 12 T/2+9.0 T+9.8 2.0 11.3-T/2 6.8 611

5 45 UG-3-0545 5.51 4 - 6 82 75 55 12 T/2+9.0 T+9.8 2.0 11.3-T/2 6.8 768

* minimum overhang is M/2

** includes 3/8" thick beam mounting plates

10

Underhung Motorized End Trucks (Refer to Fig. 2-1)

Max.

Cap.

(Tons)

Max.

Span

(ft)

En

d Truck

Model # Wheel

Dia.

(in)

Flange

Range

Std.

(in)

A

Overall

Length

(in)

B

Roller

Base

(in)

D

Wheel

Base

(in)

E *

Beam

Beyond

Span

(in)

M

End

Truck

Frame

Width

(in)

U **

Wheel

Bottom

to Beam

Top

(in)

X

Width

Beyond

Span

(in)

Y

Wheel

Running

Surface

to

Upper

Most

Part of

ET

(in)

AA

Span to

Motor

End (in)

2 35 UML/S/H/D-3-0235

4.33 3 - 6 60 53 39 12 T+8.1 1.8 11.3-T/2 6.5 T/2+11.9

(L/S)

T/2+12.3

(H)

T/2+13.3

(D)

2 50 UML/S/H/D-3-0250

4.33 3 – 6 82 75 61 12 T+8.1 1.8 11.3-T/2 6.5

3 35 UML/S/H/D-3-0335

4.92 3 – 6 60 53 35 12 T+8.2 1.9 11.3-T/2 6.5

3 50 UML/S/H/D-3-0350

4.92 3 – 6 82 75 57 12 T+8.2 1.9 11.3-T/2 6.5

5 35 UML/S/H/D-3-0535

5.51 4 - 6 60 53 33 12 T+9.8 2.0 11.3-T/2 6.8 T/2+13.7

(L/S/D)

T/2+14.2

(H)

5 50 UML/S/H/D-3-0550

5.51 4 - 6 82 75 55 12 T+9.8 2.0 11.3-T/2 6.8

* minimum overhang is M/2

** includes 3/8" thick beam mounting plates

Underhung Motorized End Truck - Gear Motors

End Truck

Model # Travel

Speed

(FPM)

Motor

Power

(Hp)

Ea. of

Two

Current

(AMPS) Ea.

of Two

Travel

Speed

(FPM)

Motor

Power

(Hp)

Ea. of

Two

Current

(AMPS) Ea. of

Two

Travel

Speed

(FPM)

Motor

Power (Hp)

Ea. of Two

Current (AMPS)

Ea. of Two Motor

End

Truck

Weight

(lbs./pr)

230V 460V 230V 460V 230V 460V

UML/S/H/D-3-0235 40/80 0.33 1.6 1.0 120 0.5 2.1 1.3 80/20 0.33/0.08 1.6/1.1 0.9/0.8 522

UML/S/H/D-3-0250 40/80 0.33 1.6 1.0 120 0.5 2.1 1.3 80/20 0.33/0.08 1.6/1.1 0.9/0.8 659

UML/S/H/D-3-0335 40/80 0.33 1.6 1.0 120 0.5 2.1 1.3 80/20 0.33/0.08 1.6/1.1 0.9/0.8 543

UML/S/H/D-3-0350 40/80 0.33 1.6 1.0 120 0.5 2.1 1.3 80/20 0.33/0.08 1.6/1.1 0.9/0.8 680

UML/S/H/D-3-0535 40/80 0.50 2.1 1.3 120 1.0 3.3 2.0 80/20 0.50/0.13 2.0/1.5 1.2/0.9 638

UML/S/H/D-3-0550 40/80 0.50 2.1 1.3 120 1.0 3.3 2.0 80/20 0.50/0.13 2.0/1.5 1.2/0.9 795

Speed Code

L - Designates the speed of 40 feet per minute

S - Designates the speed of 80 feet per minute

H - Designates the speed of 120 feet per minute

D - Designates the speed of dual speed 80/20 feet per minute

Product code derivation - example: UML/S/H/D-3-0235

U - Underhung

M - Motorized

L/S/H/D - Speed code - available in 40, 80, 120, or dual 80/20 feet per minute - choose desired speed

3 – Series number

02 – Capacity - 2 ton

35 – Maximum span - 35 feet

11

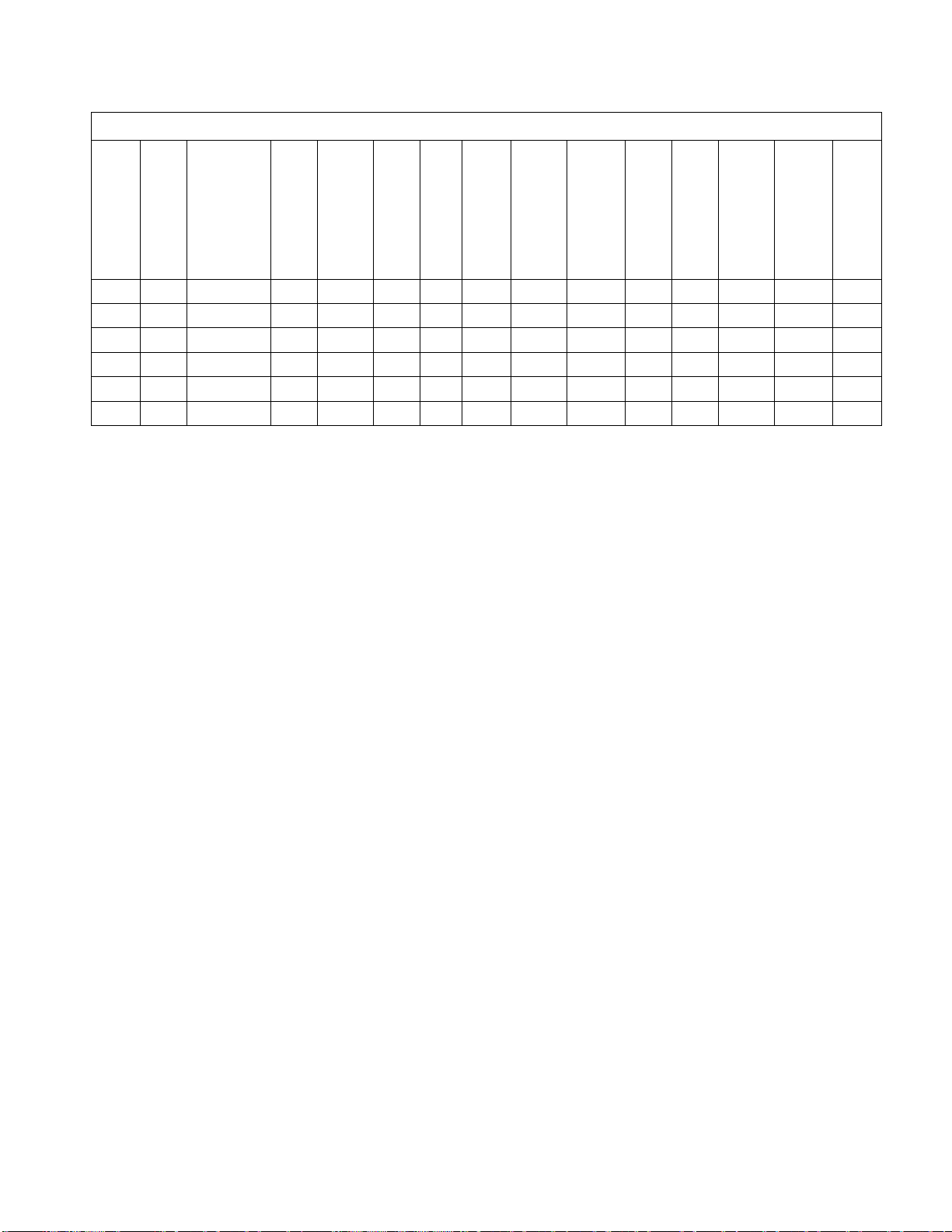

Max-E-Lift Underhung Geared End Trucks (Refer to Fig. 2-1)

Max.

Cap.

(Tons)

Max.

Span

(ft)

End Truck

Model # Wheel

Diame

ter (in)

Flange

Range

Std. (in)

A

Overal

l

Length

(in)

B

Roller

Base

(in)

D

Wheel

Base

(in)

E *

Beam

Beyond

Span

(in)

J

Hand

Wheel

Offset

(in)

M

End

Truck

Frame

Width

(in)

U **

Wheel

Botto

m to

Beam

Top

(in)

X

Width

Beyond

Span

(in)

Y

Wheel

Running

Surface

to Upper

Most

Part of

ET

(in)

End

Truck

Weight

(lbs/pr)

2 35 MUG-3-0235 4.33 3 - 6 87 80 66 12 T/2+9.0 T+8.1 1.8 11.3-T/2 6.5 671

2 45 MUG-3-0245 4.33 3 – 6 99 92 78 12 T/2+9.0 T+8.1 1.8 11.3-T/2 6.5 746

3 35 MUG-3-0335 4.92 3 – 6 91 84 66 12 T/2+8.9 T+8.2 1.9 11.3-T/2 6.7 722

3 45 MUG-3-0345 4.92 3 – 6 103 96 78 12 T/2+8.9 T+8.2 1.9 11.3-T/2 6.7 797

5 35 MUG-3-0535 5.51 4 - 6 95 88 68 12 T/2+9.0 T+9.8 2.0 11.3-T/2 6.8 861

5 45 MUG-3-0545 5.51 4 - 6 107 100 80 12 T/2+9.0 T+9.8 2.0 11.3-T/2 6.8 946

* minimum overhang is M/2

** includes 3/8" thick beam mounting plates

12

Max-E-Lift Underhung Motorized End Trucks (Refer to Fig. 2-1)

Max.

Cap.

(Tons)

Max.

Span

(ft)

End Truck

Model # Whl.

Dia.

(in)

Flange

Range

Std. (in)

A

Overall

Length

(in)

B

Roller

Base

(in)

D

Wheel

Base

(in)

E *

Beam

Beyond

Span

(in)

M

End

Truck

Frame

Width

(in)

U **

Wheel

Botto

m to

Beam

Top

(in)

X

Width

Beyond

Span

(in)

Y

Wheel

Running

Surface

to

Upper

Most

Part of

ET

(in)

AA

Span to

Motor

End (in)

2 35 MUML/S/H/D-3-0235 4.33 3 - 6 87 80 66 12 T+8.1 1.8 11.3-T/2

6.5 T/2+11.9

(L/S)

T/2+12.3

(H)

T/2+13.3

(D)

2 50 MUML/S/H/D-3-0250 4.33 3 – 6 99 92 78 12 T+8.1 1.8 11.3-T/2

6.5

3 35 MUML/S/H/D-3-0335 4.92 3 – 6 91 84 66 12 T+8.2 1.9 11.3-T/2

6.5

3 50 MUML/S/H/D-3-0350 4.92 3 – 6 103 96 78 12 T+8.2 1.9 11.3-T/2

6.5

5 35 MUML/S/H/D-3-0535 5.51 4 - 6 95 88 68 12 T+9.8 2.0 11.3-T/2

6.8 T/2+13.7

(L/S/D)

T/2+14.2

(H)

5 50 MUML/S/H/D-3-0550 5.51 4 - 6 107 100 80 12 T+9.8 2.0 11.3-T/2

6.8

* minimum overhang is M/2

** includes 3/8" thick beam mounting plates

Max-E-Lift Underhung Motorized End Truck - Gear Motors

End Truck Model # Travel

Speed

(FPM)

Motor

Power

(Hp)

Ea. of

Two

Current

(AMPS) Ea. of

Two

Travel

Speed

(FPM)

Motor

Power

(Hp)

Ea. of

Two

Current

(AMPS) Ea.

of Two

Travel

Speed

(FPM)

Motor

Power (Hp)

Ea. of Two

Current (AMPS)

Ea. of Two Motor

End

Truck

Weight

(lbs/pr)

230V 460V 230V

460V 230V 460V

MUML/S/H/D-3-0235 40/80 0.33 1.6 1.0 120 0.5 2.1 1.3 80/20 0.33/0.08 1.6/1.1

0.9/0.8 690

MUML/S/H/D-3-0250 40/80 0.33 1.6 1.0 120 0.5 2.1 1.3 80/20 0.33/0.08 1.6/1.1

0.9/0.8 765

MUML/S/H/D-3-0335 40/80 0.33 1.6 1.0 120 0.5 2.1 1.3 80/20 0.33/0.08 1.6/1.1

0.9/0.8 736

MUML/S/H/D-3-0350 40/80 0.33 1.6 1.0 120 0.5 2.1 1.3 80/20 0.33/0.08 1.6/1.1

0.9/0.8 811

MUML/S/H/D-3-0535 40/80 0.50 2.1 1.3 120 1.0 3.3 2.0 80/20 0.50/0.13 2.0/1.5

1.2/0.9 888

MUML/S/H/D-3-0550 40/80 0.50 2.1 1.3 120 1.0 3.3 2.0 80/20 0.50/0.13 2.0/1.5

1.2/0.9 973

Speed Code

L - Designates the speed of 40 feet per minute

S - Designates the speed of 80 feet per minute

H - Designates the speed of 120 feet per minute

D - Designates the speed of dual speed 80/20 feet per minute

Product code derivation - example: MUML/S/H/D-3-0235

M - Max-E

U - Underhung

M – Motorized

L/S/H/D - Speed code - available in 40, 80, 120, or dual 80/20 feet per minute - choose desired speed

3 – Series number

02 – Capacity - 2 ton

35 – Maximum span - 35 feet

13

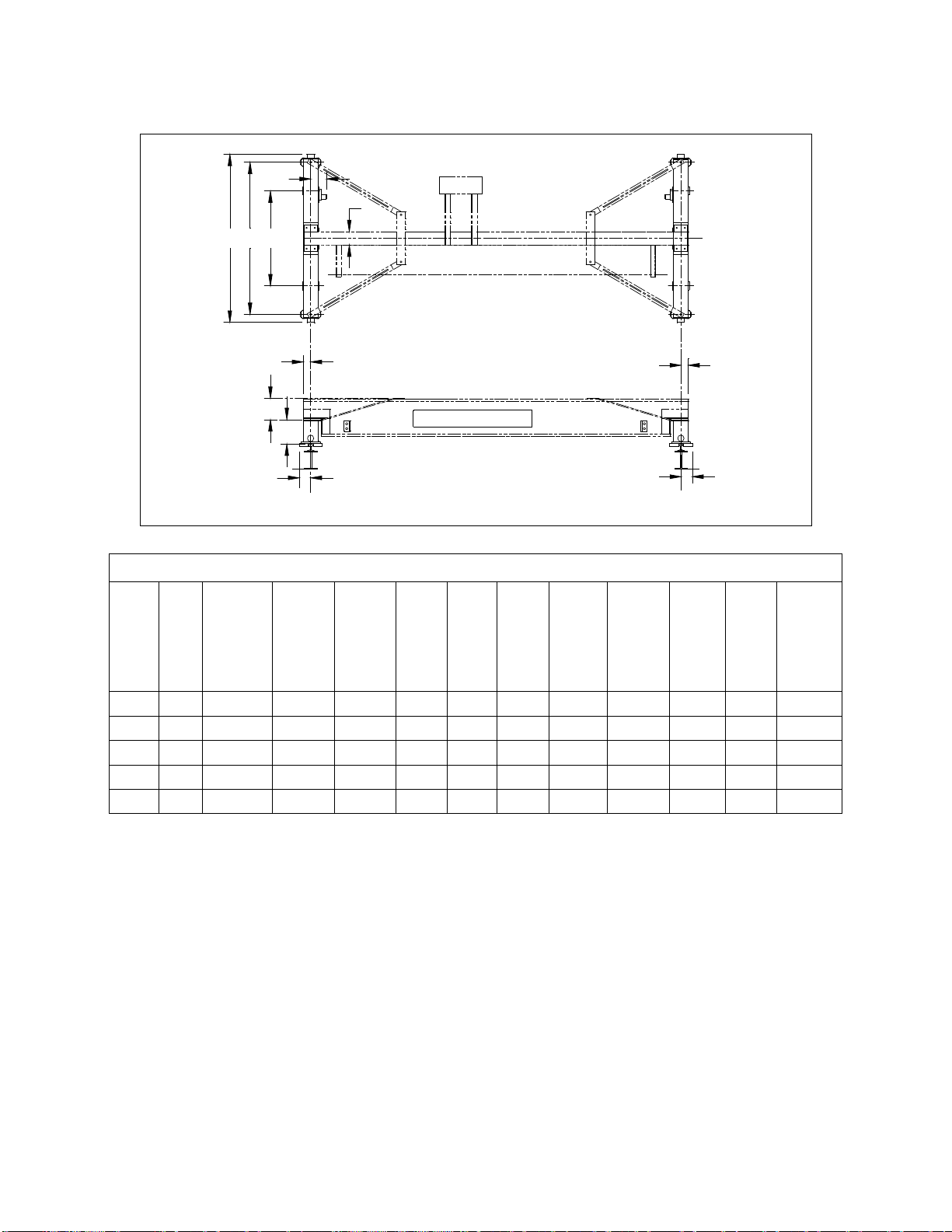

2.2 Specifications for Top Running End Trucks

BDA

EE

X

YHarrington Hoists, Inc.

X

F

AA

U

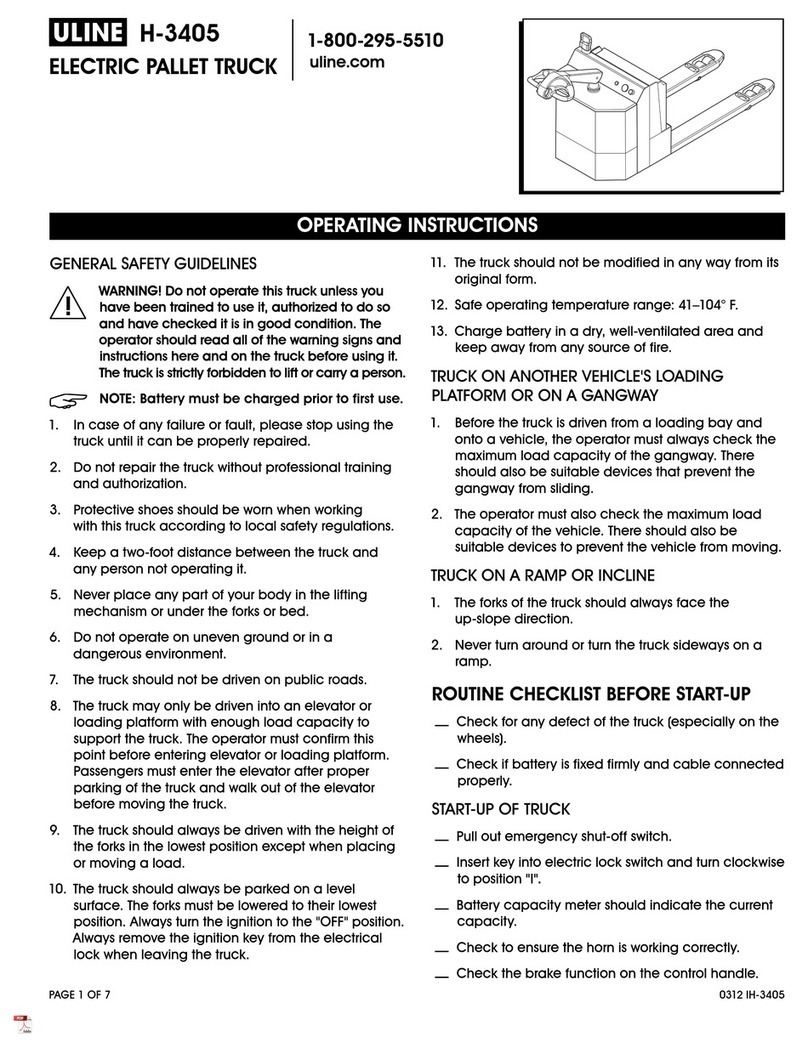

Figure 2-2 Top Running End Truck Dimensions

Top Running Push (Manual) End Trucks (Refer to Fig. 2-2)

Max.

Cap.

(Tons)

Max.

Span

(ft)

End Truck

Model # Wheel

Diameter

(in)

Sug.

Min.

Runway

Rail

(ACSE#)

A

Overall

Length

(in)

B

Roller

Base

(in)

D

Wheel

Base

(in)

E

Beam

Beyond

Span

(in)

U

Crane

Height

Above

End

Truck

(in)

X*

Width

Beyond

Span

(in)

Y

Top of

Rail to

Top of

End

Truck

(in)

End

Truck

Weight

(lbs./pr)

1 35 TP-3-0135 3.74 30 61 53 43 2.4 8.4** 4.6 7.1 242

1 45 TP-3-0145 3.74 30 98 90 80 2.4 8.4** 4.6 7.1 338

2 45 TP-3-0245 6.10 30 99 91 80 4.1 8.4** 4.6 7.1 454

3 35 TP-3-0335 6.10 30 62 54 43 4.1 8.4** 4.6 7.1 337

5 35 TP-3-0535 6.10 40 62 54 43 4.1 8.5 4.7 9.2 420

* Based on suggested minimum runway rail.

** 10.4” for cranes using a 10” beam

14

Top Running Geared End Trucks (Refer to Fig. 2-2)

Max.

Cap.

(Tons)

Max.

Span

(ft)

End Truck

Model # Wheel

Diameter

(in)

Suggested

Min.

Runway

Rail

(ACSE#)

A

Overall

Length

(in)

B

Roller

Base

(in)

D

Wheel

Base

(in)

E

Beam

Beyond

Span

(in)

J

Hand

Wheel

Offset

(in)

U

Crane

Height

Above

End

Truck

(in)

X*

Width

Beyond

Span

(in)

Y

Top of

Rail to

Top of

End

Truck

(in)

End

Truck

Weight

(lbs./

pr)

1 35 TG-3-0135 3.74 30 61 53 43 2.4 9.7 8.4** 4.6 7.1 264

1 50 TG-3-0150 3.74 30 98 90 80 2.4 9.7 8.4** 4.6 7.1 360

3 35 TG-3-0335 6.10 30 62 54 43 4.1 10.0 8.4** 4.6 7.1 359

3 50 TG-3-0350 6.10 30 99 91 80 4.1 10.0 8.4** 4.6 7.1 477

5 35 TG-3-0535 6.10 40 62 54 43 4.1 10.0 8.5 4.7 9.2 450

5 50 TG-3-0550 8.27 40 99 90 74 3.9 10.3 8.5 4.7 9.3 703

* Based on suggested minimum runway rail.

** 10.4” for cranes using a 10” beam

15

Top Running Motorized End Trucks (Refer to Fig. 2-2)

Max.

Cap.

(Tons)

Max.

Span

(ft)

End Truck

Model # Wheel

Diameter

(in)

Sug. Min.

Runway

Rail

(ACSE#)

A

Overall

Length

(in)

B

Roller

Base

(in)

D

Wheel

Base

(in)

E

Beam

Beyond

Span

(in)

U

Crane

Height

Above

End

Truck

(in)

X*

Width

Beyond

Span

(in)

Y

Top of

Rail to

Top of

End

Truck

(in)

AA

Span to

Motor End

(in)

1 35 TML/S/H/D-3-0135 3.74 30 61 53 43 2.4 8.4** 4.6 7.1 12.7 (L/S)

13.1 (H)

14.0 (D)

1 60 TML/S/H/D-3-0160 3.74 30 98 90 80 2.4 8.4** 4.6 7.1

3 35 TML/S/H/D-3-0335 6.10 30 62 54 43 4.1 8.4** 4.6 7.1 13.0 (L/S)

13.4 (H)

14.3 (D)

3 60 TML/S/H/D-3-0360 6.10 30 99 91 80 4.1 8.4** 4.6 7.1

5 35 TML/S/H/D-3-0535 6.10 40 62 54 43 4.1 8.5 4.7 9.2

5 60 TML/S/H/D-3-0560 8.27 40 99 90 74 3.9 8.5 4.7 9.3 15.0 (L/S/D)

15.4 (H)

10 35 TML/S/H/D-3-1035 9.84 60 63 53 37 6.0 12.5 6.3 11.3 17.4 (L/S/D)

18.7 (H)

10 60 TML/S/H/D-3-1060 9.84 60 100 90 74 6.0 12.5 6.3 11.3

* Based on suggested minimum runway rail.

** 10.4” for cranes using a 10” beam

16

Top Running Motorized End Truck - Gear Motors

End Truck

Model # Travel

Speed

(FPM)

Motor

Power

(Hp)

Ea. of

Two

Current

(AMPS) Ea. of

Two

Travel

Speed

(FPM)

Motor

Power

(Hp)

Ea. of

Two

Current

(AMPS) Ea. of

Two

Travel

Speed

(FPM)

Motor

Power (Hp)

Ea. of Two

Current

(AMPS) Ea. of

Two

Motor

End

Truck

Weight

(lbs./ pr)

230V 460V 230V 460V 230V 460V

TML/S/H/D-3-0135 40/80 0.33 1.6 1.0 120 0.5 2.1 1.3 80/20 0.33/0.08 1.6/1.1 0.9/0.8

325

TML/S/H/D-3-0160 40/80 0.33 1.6 1.0 120 0.5 2.1 1.3 80/20 0.33/0.08 1.6/1.1 0.9/0.8

422

TML/S/H/D-3-0335 40/80 0.33 1.6 1.0 120 0.5 2.1 1.3 80/20 0.33/0.08 1.6/1.1 0.9/0.8

421

TML/S/H/D -3-0360 40/80 0.33 1.6 1.0 120 0.5 2.1 1.3 80/20 0.33/0.08 1.6/1.1 0.9/0.8

538

TML/S/H/D-3-0535 40/80 0.33 1.6 1.0 120 0.5 2.1 1.3 80/20 0.33/0.08 1.6/1.1 0.9/0.8

512

TML/S/H/D-3-0560 40/80 0.50 2.1 1.3 120 1.0 3.3 2.0 80/20 0.50/0.13 2.0/1.5 1.2/0.9

739

TML/S/H/D-3-1035 40/80 1.00 3.3 2.0 120 2.0 5.8 3.1 80/20 1.00/0.25 3.7/2.1 2.3/1.4

883

TML/S/H/D-3-1060 40/80 1.00 3.3 2.0 120 2.0 5.8 3.1 80/20 1.00/0.25 3.7/2.1 2.3/1.4

1063

* Based on suggested minimum runway rail.

Speed Code

L - Designates the speed of 40 feet per minute

S - Designates the speed of 80 feet per minute

H - Designates the speed of 120 feet per minute

D - Designates the speed of dual speed 80/20 feet per minute

Product code derivation - example: TML/S/H/D-3-0135

T -Top Running

M - Motorized

L/S/H/D - Speed code - available in 40, 80, 120, or dual 80/20 feet per minute - choose desired speed

3 - Series number

01 - Capacity - 1 ton

35 - Maximum span - 35 feet

Max-E-Lift Top Running Geared End Trucks (Refer to Fig. 2-2)

Max.

Cap.

(Tons)

Max.

Span

(ft)

End Truck

Model # Wheel

Diamet

er (in)

Sug.

Min.

Runway

Rail

(ASCE#)

A

Overall

Length

(in)

B

Roller

Base

(in)

D

Wheel

Base

(in)

E

Beam

Beyond

Span

(in)

J

Hand

Wheel

Offset

(in)

K

Beam

Gauge

(in)

W *

Width

Beyond

Span

(in)

Y

Top of

Rail to

Top of

End

Truck

(in)

End

Truck

Weight

(lbs./pr)

1 35 MTG-3-0135 3.74 30 72 64 54 2.06 9.7 36 4.6 7.1 310

1 50 MTG-3-0150 3.74 30 111 103 93 2.06 9.7 36 4.6 7.1 411

3 35 MTG-3-0335 6.10 30 75 67 56 3.75 10.0 36 4.6 7.1 417

3 50 MTG-3-0350 6.10 30 112 104 93 3.75 10.0 36 4.6 7.1 538

5 35 MTG-3-0535 6.10 40 75 67 56 3.75 10.0 36 4.7 9.2 539

5 50 MTG-3-0550 8.27 40 112 103 87 3.50 10.3 36 4.7 9.3 789

17

Max-E-Lift Top Running Motorized End Trucks (Refer to Fig. 2-2)

Max.

Cap.

(Tons)

Max.

Span

(ft)

End Truck

Model # Wheel

Diameter

(in)

Sug. Min.

Runway

Rail

(ASCE#)

A

Overall

Length

(in)

B

Roller

Base

(in)

D

Wheel

Base

(in)

E

Beam

Beyond

Span

(in)

K

Beam

Gauge

(in)

W *

Width

Beyond

Span

(in)

Y

Top of

Rail to

Top of

End

Truck

(in)

AA

Span to

Motor End

(in)

1 35 MTML/S/H/D-3-0135 3.74 30 72 64 54 2.06 36 4.6 7.1 12.7 (L/S)

13.1 (H)

14.0 (D)

1 60 MTML/S/H/D-3-0160 3.74 30 111 103 93 2.06 36 4.6 7.1

3 35 MTML/S/H/D-3-0335 6.10 30 75 67 56 3.75 36 4.6 7.1 13.0 (L/S)

13.4 (H)

14.3 (D)

3 60 MTML/S/H/D-3-0360 6.10 30 112 104 93 3.75 36 4.6 7.1

5 35 MTML/S/H/D-3-0535 6.10 40 75 67 56 3.75 36 4.7 9.2

5 60 MTML/S/H/D-3-0560 8.27 40 112 103 87 3.50 36 4.7 9.3 15.0

(L/S/D)

15.4 (H)

10 35 MTML/S/H/D-3-1035 9.84 60 93 83 67 5.25 48 6.3 11.3 17.4

(L/S/D)

18.7 (H)

10 60 MTML/S/H/D-3-1060 9.84 60 113 103 87 5.25 48 6.3 11.3

Max-E Top Running Motorized End Truck - Gear Motors

End Truck Model # Travel

Speed

(FPM)

Motor

Power

(Hp)

Ea. of

Two

Current

(AMPS) Ea. of

Two

Travel

Speed

(FPM)

Motor

Power

(Hp)

Ea. of

Two

Current

(AMPS) Ea. of

Two

Travel

Speed

(FPM)

Motor

Power (Hp)

Ea. of Two

Current

(AMPS) Ea. of

Two

Motor

End

Truck

Weight

(lbs./pr)

230V 460V 230V 460V 230V 460V

MTML/S/H/D-3-0135 40/80 0.33 1.6 1.0 120 0.5 2.1 1.3 80/20 0.33/0.08 1.6/1.1

0.9/0.8

340

MTML/S/H/D-3-0160 40/80 0.33 1.6 1.0 120 0.5 2.1 1.3 80/20 0.33/0.08 1.6/1.1

0.9/0.8

441

MTML/S/H/D-3-0335 40/80 0.33 1.6 1.0 120 0.5 2.1 1.3 80/20 0.33/0.08 1.6/1.1

0.9/0.8

526

MTML/S/H/D -3-0360 40/80 0.33 1.6 1.0 120 0.5 2.1 1.3 80/20 0.33/0.08 1.6/1.1

0.9/0.8

647

MTML/S/H/D-3-0535 40/80 0.33 1.6 1.0 120 0.5 2.1 1.3 80/20 0.33/0.08 1.6/1.1

0.9/0.8

648

MTML/S/H/D-3-0560 40/80 0.50 2.1 1.3 120 1.0 3.3 2.0 80/20 0.50/0.13 2.0/1.5

1.2/0.9

818

MTML/S/H/D-3-1035 40/80 1.00 3.3 2.0 120 2.0 5.8 3.1 80/20 1.00/0.25 3.7/2.1

2.3/1.4

1105

MTML/S/H/D-3-1060 40/80 1.00 3.3 2.0 120 2.0 5.8 3.1 80/20 1.00/0.25 3.7/2.1

2.3/1.4

1202

18

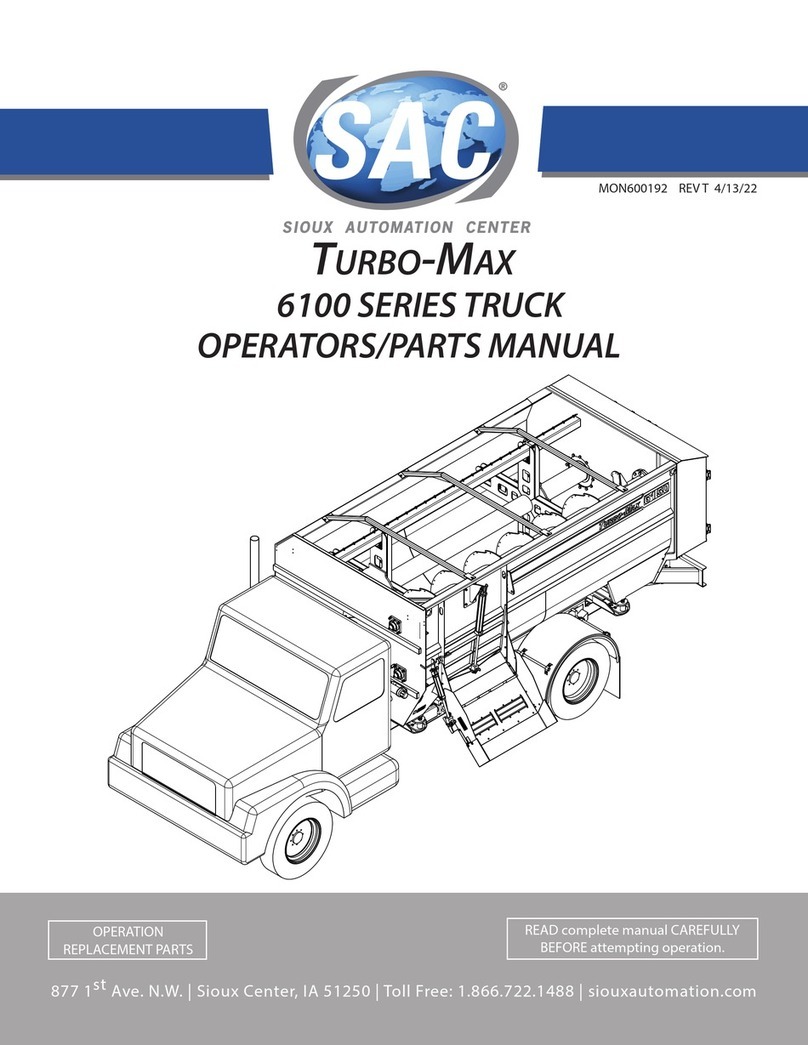

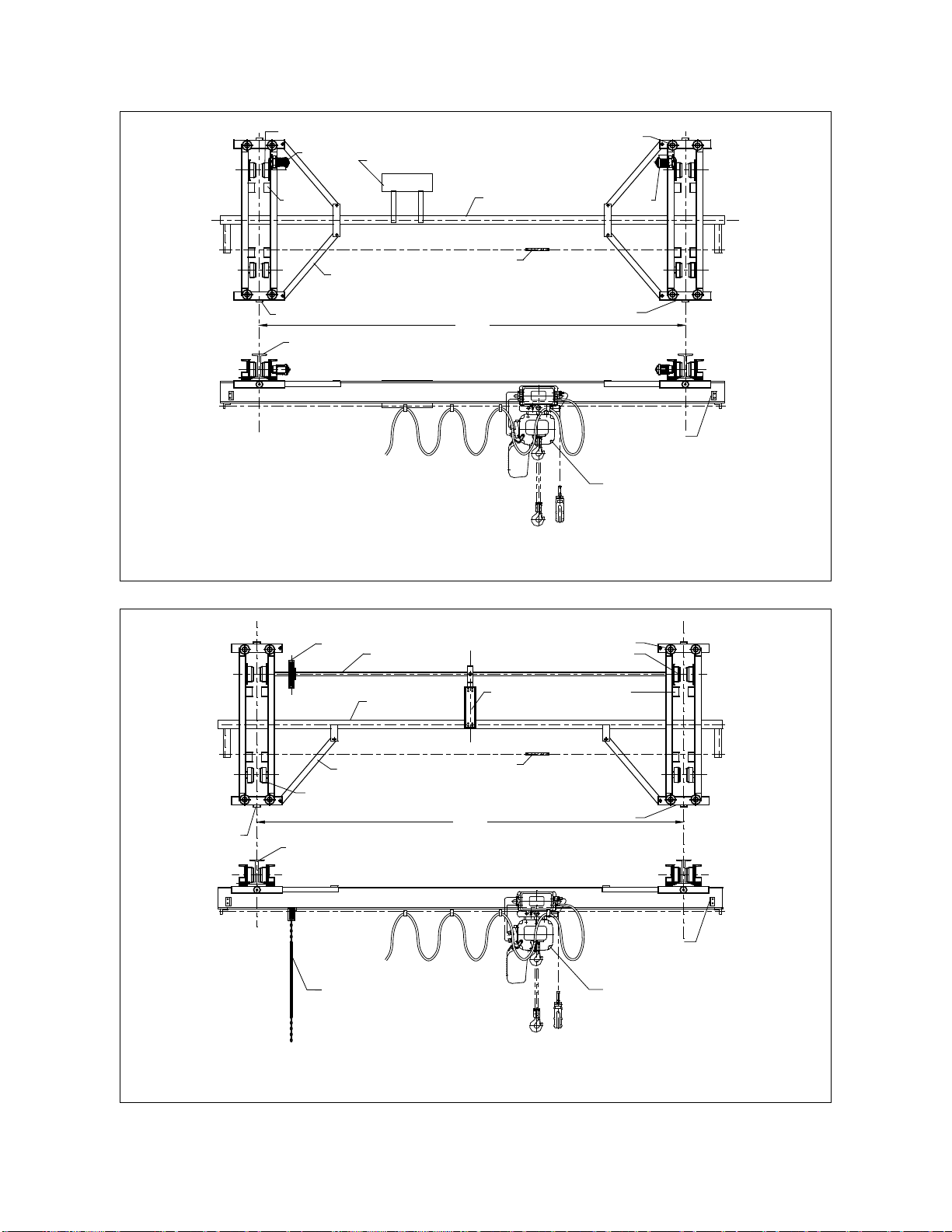

2.3 Component Names

RUNWAY BEAM

BRACES

STOP

DROP

SPAN

GUIDE WIRE

BRIDGE BEAM MOTOR

MOTOR BRIDGE CONTROL BOX

TYPICAL CRANE SYSTEM WITH UNDERHUNG MOTORIZED END TRUCKS

GUIDE ROLLER

BUMPER

GEARED WHEEL

TROLLEY STOP

END BRACKET

TYPICAL HOIST & TROLLEY

Figure 2-3

FOR DRIVE SHAFT

SUPPORT ASSEMBLIES

RUNWAY BEAM

BRACE

BRIDGE BEAM

SPAN

DRIVE SHAFT

HAND WHEEL

STOP

DROP

GUIDE WIRE

TYPICAL CRANESYSTEM WITH UNDERHUNG GEARED END TRUCKS

GUIDE ROLLER

GEARED WHEEL

END BRACKET

TROLLEY STOP

TYPICAL HOIST & TROLLEY

BUMPER

HAND CHAIN

PLAIN WHEEL

Figure 2-4

19

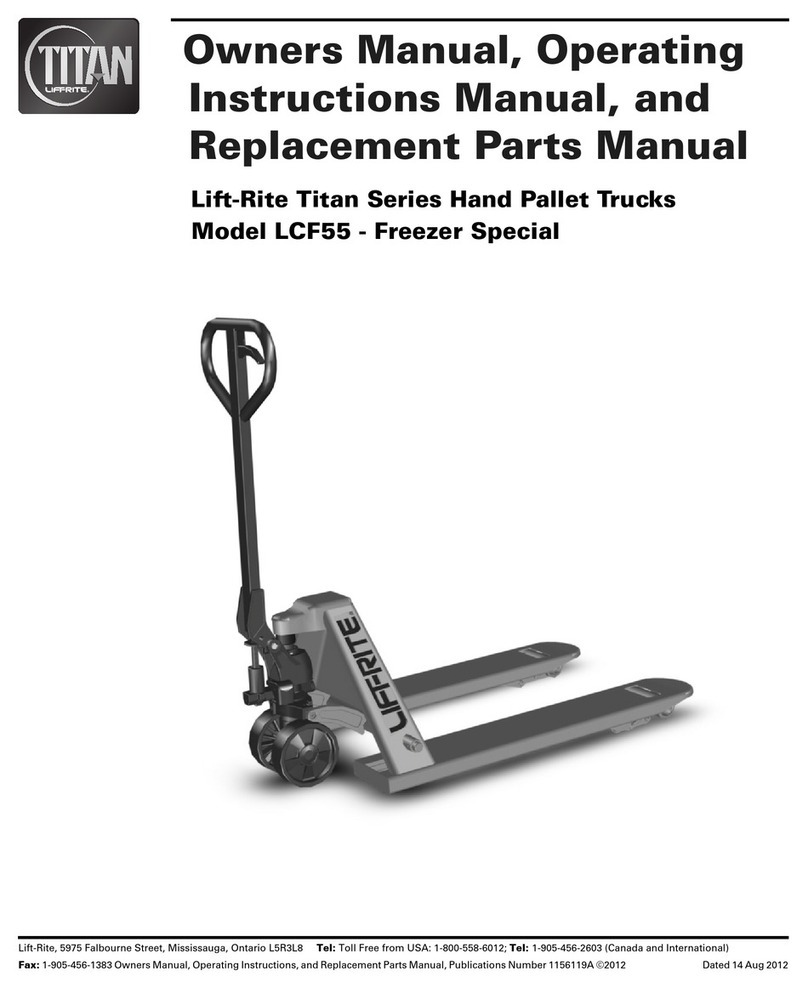

BRIDGE CONTROL BOX

GUIDE WIRE

MOTOR

BRACES

BRIDGE BEAM

END TRUCK

F

SPAN

TYPICAL CRANE SYSTEM WITH TOP RUNNING MOTORIZED END TRUCK

GUIDE ROLLERS

BUMPER

TROLLEY STOP

RUNWAY RAIL

RAIL SUPPORT STRUCTURE

Figure 2-5

BRACES

F

BRIDGE BEAM

END TRUCK

SPAN

FOR DRIVE SHAFT

SUPPORT ASSEMBLIES

DRIVE SHAFT

HAND WHEEL

GUIDE WIRE

TYPICALCRANE SYSTEM WITH TOP RUNNING GEARED END TRUCK

GUIDE ROLLERS

BUMPER

TROLLEY STOP

RAIL SUPPORT STRUCTURE

RUNWAY RAIL

HAND CHAIN

TYPICAL HOIST & TROLLEY

Figure 2-6

20

2.4 Bridge Crane Design Requirements -For proper selection of end trucks to meet your particular

needs, refer to the Harrington brochure “Choosing the Crane to Fit Your Needs” or our latest catalog.

2.4.1 CRANE RUNWAYS

Supporting Structure - Ensure that the supporting structure for the runways is adequate. If necessary

consult a professional that is qualified to evaluate the adequacy of the runway's supporting structure.

Installing a crane system on runways supported by inadequate supporting structure

could result in death or serious injury, and property damage.

Runway Design - Ensure that the runways meet the design requirements of the CMAA

Specification #70 or #74 whichever applies.

Runway Alignment - Ensure that the runways meet the runway alignment requirements of

CMAA Specification #70 or #74, whichever applies. For your convenience, Harrington has

provided these alignment criteria in Table 2-1 below.

Improper design, fabrication, or installation of crane runways could result in death or

serious injury, and property damage.

Table 2-1 CMAA Design Requirements

Item Overall Tolerance Maximum Rate

Of Change

Crane span (L) measured at crane wheel contact surface.

L < 50’

A = 3/16”

50’

< L < 100’

A = 1/4”

L > 100’

A = 3/8”

1/4” in 20’-0”

Straightness (B)

B = 3/8” 1/4” in 20’-0”

Elevation (C)

C =3 /8” 1/4” in 20’-0”

TOP RUNNING Transverse rail to rail elevation (D).

L < 50’

D = 3/16”

50’

< L < 100’

D = 1/4”

L > 100’

D = 3/8”

1/4” in 20’-0”

UNDER RUNNING Transverse girder to girder elevation (D).

Table of contents

Other KITO Truck manuals