5

ADJUSTMENT

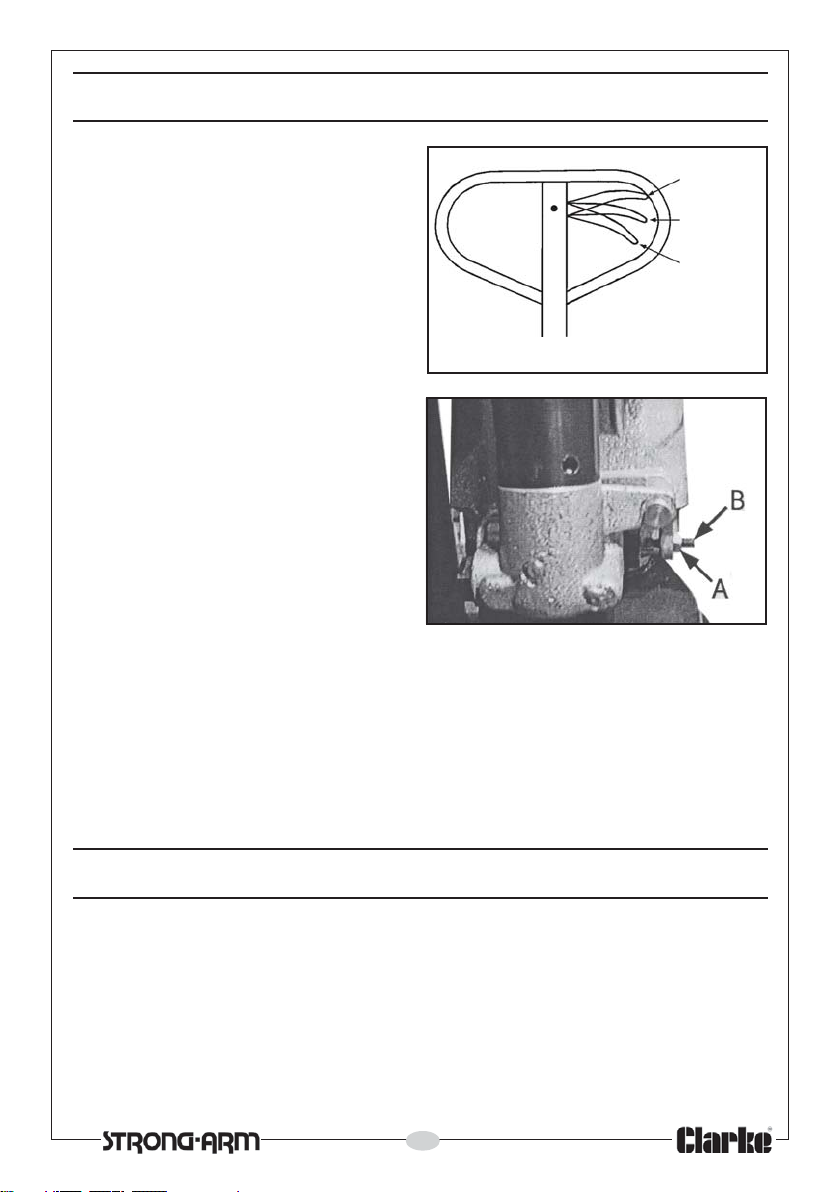

The control lever has three positions

shown in Fig 4 and indicated by the

label on the handle.

With the lever pulled to the upper

position, the forks will lower.

The middle position allows the load

to be transported.

The lower position will cause the forks

to lift when the handle is pumped.

1. Set the control lever to its lowest

position (i.e. Lever in its LIFT

position).

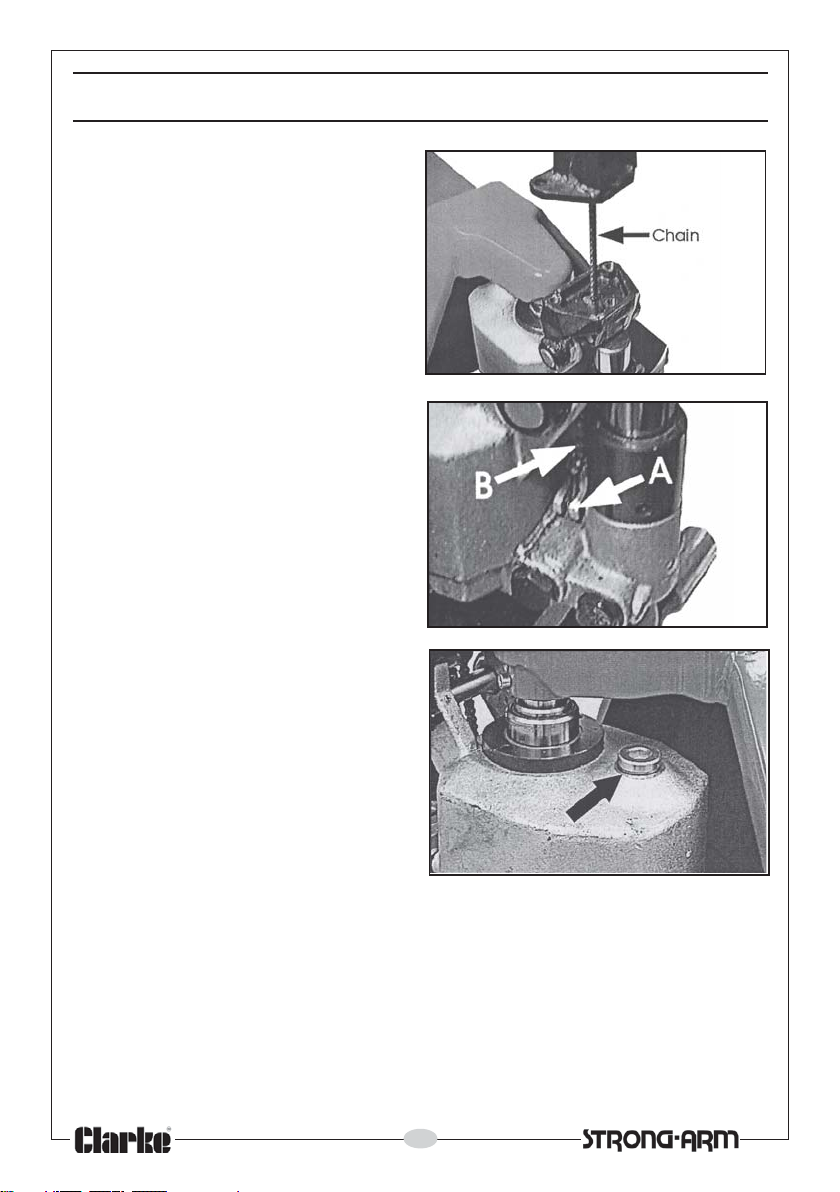

2. Check to ensure there is no

tension on the chain. If necessary,

adjust the locknut on the

threaded rod attached to the

end of the chain, until the free

movement on the end of the

control lever, when in its lowest

position, is approx 1/4”.

3. Pump the handle and then lower to test its operation.

4 If the forks rise but lower immediately you stop pumping or only lift slowly,

slacken the locknut ‘A’ and screw the adjuster ‘B’ anticlockwise half a turn

as shown in Fig 5 and try again.

5. If the forks do not lower when the control handle is in the LOWER

position, turn the adjusting screw (A) in clockwise until the handle lowers

the forks. Tighten locknut ‘B’. Check it’s operation in the TRANSPORT

position.

OPERATION

Before using the pallet truck always read the safety instructions in this manual

and the labelling on the product. The rated capacity of the truck assumes an

evenly distributed load with it’s centre being at the halfway point along the

length of the forks.

With the forks in the lowest position, manoeuvre the truck so that it is adjacent

to the pallet. Ensure the length of the forks match the length of the pallet.

Always position the pallet truck carefully, ensuring the load is centred about

Fig. 4

Fig. 5

To Lower

Transport

position

To Lift