5

KLC Generation 2 H3.2 Installation and Technical Guide

1 General Information

Greenguard®Environmental Institute

MicroPro®is environmentally sustainable, this is demonstrated in low leaching of treatment

preservatives from the timber, low volatile organic compound (VOCs) emissions and the award

of the GREENGUARD Children and Schools’ Certification from the Greenguard®Environmental

Global GreenTag International - GreenRate™

MicroPro®Wood Treatment Technology has received a Global GreenTag GreenRate™ Level A

award under Version 4.0 of the Global GreenTag International Product Certification Standard. It

is the highest-level achievement for a product under Global GreenTag’s GreenRate™ product

rating system – declared by the certification body as ‘Fit-for-Purpose’ and confirmed for Green

Building compliance.

Global GreenTag International - Health Declaration

The GreenTag™ Product Health Declaration proves that Koppers MicroPro®Wood Treatment

Technology is safe for human health (and ecosystems) and can be used with absolute peace

of mind in workplace and residential building projects. Reducing risks for Building, Design and

Procurement Professionals whilst supporting the user and occupant’s health and wellbeing

compared to products that don’t.

The blanks are then kiln dried (KD) to a pre-determined moisture content. The KD H3.2 substrate is then profiled to various

Weatherboards, Fascia, Finishing Boards (D4S), box corners and other profiles.

To complement these appearance grade products, a dual coat oil based (alkyd) priming system is applied.

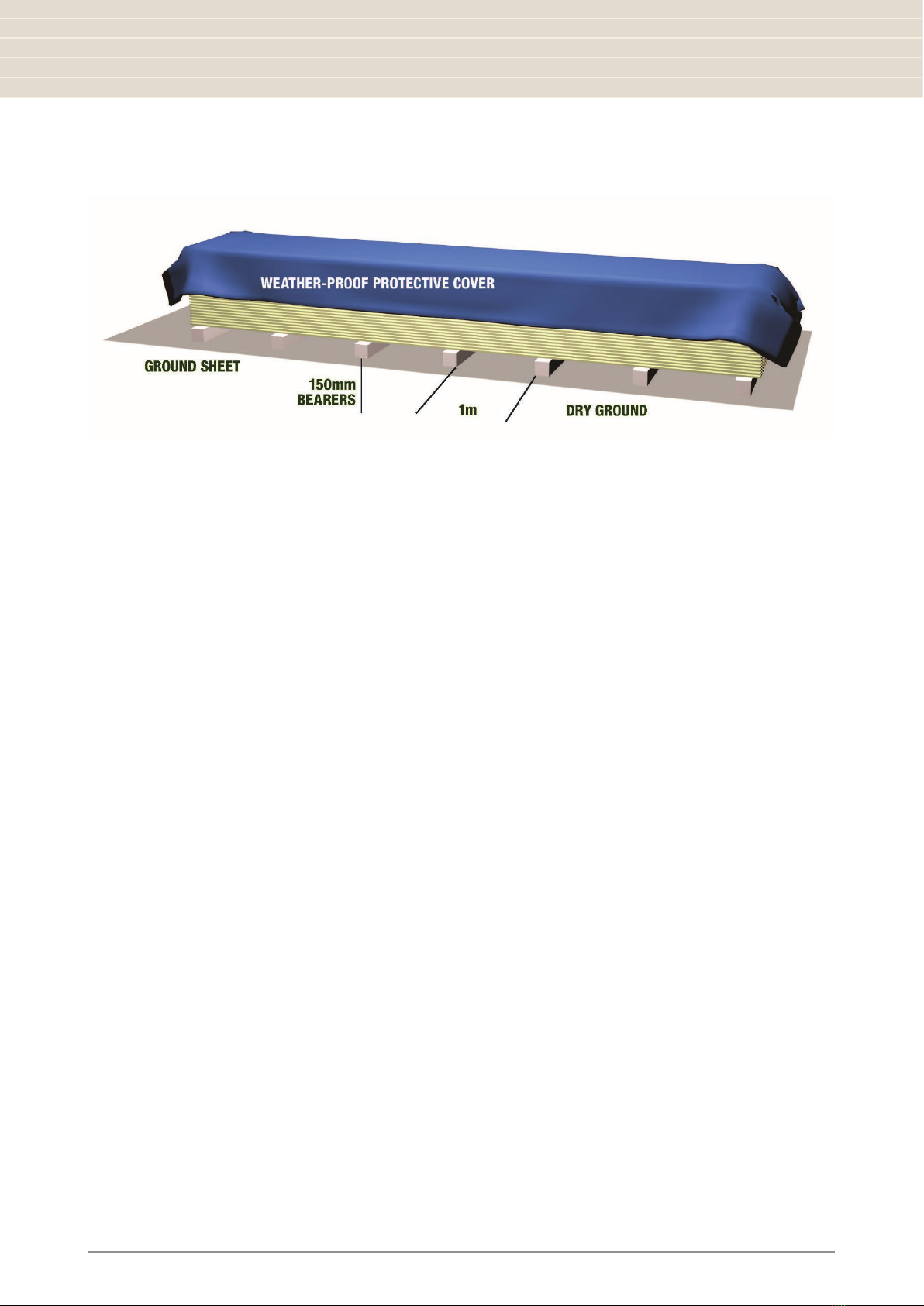

Note: Pre-priming does not waterproof the product and care must be taken to ensure dryness of product before final

painting.

When using pre primed weatherboards and fascia ensure top coat painting occurs soon as possible after installation.

Refer 4.0 Painting page 18

KLC will not “Warranty” any Generation 2 H3.2 product that have not been stored correctly and installed by a professional

Licenced Building Practitioner and as per the NZ Building Code NZS 3604 and painted in accordance with AS/NZS 2311

2017.

KLC Generation 2 exterior cladding systems have been designed for use in residential and small commercial building

applications.

KLC Generation 2 H3.2 exterior cladding systems shall be either direct fixed to framing over a wall underlay or fixed to a

Generation 2 H3.2 cavity batten, this method is described in the Acceptable Solution E2/AS1 paragraph 9.1.8.

Timber weatherboards are included in the Acceptable Solution E2/AS1, section 3.0.

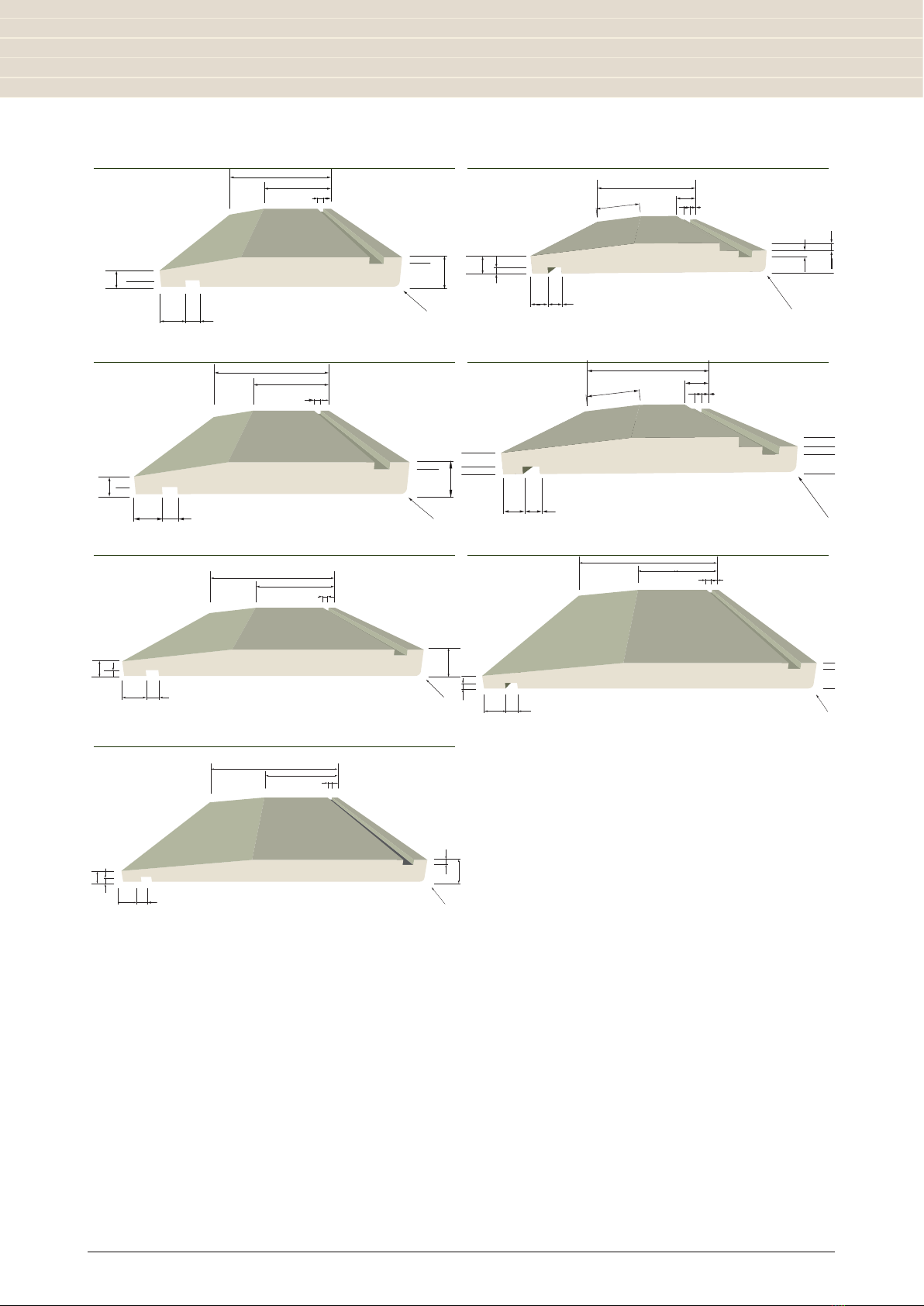

All types of weatherboard profiles may be used in low risk buildings. Only bevel back, rusticated and vertical shiplap

weatherboards should be used in high risk buildings. For information on requirements for rained ventilated cavities refer to

the Acceptable Solution E2/ AS1, paragraph 9.1.8.

KLC Generation 2 H3.2 weatherboards are limited to use in buildings with a risk matrix score of 20 or below as outlined in

E2/AS1 paragraphs 3.4.1 to 3.4.3 (Weather Tightness Matrix)

Weatherboard cladding systems are an acceptable solution under the terms of the New Zealand Building Code E2/AS1.

NZBC E2/AS1 section 1.5 specifies that the design, installation and alteration of cladding is classed as restricted building

work.