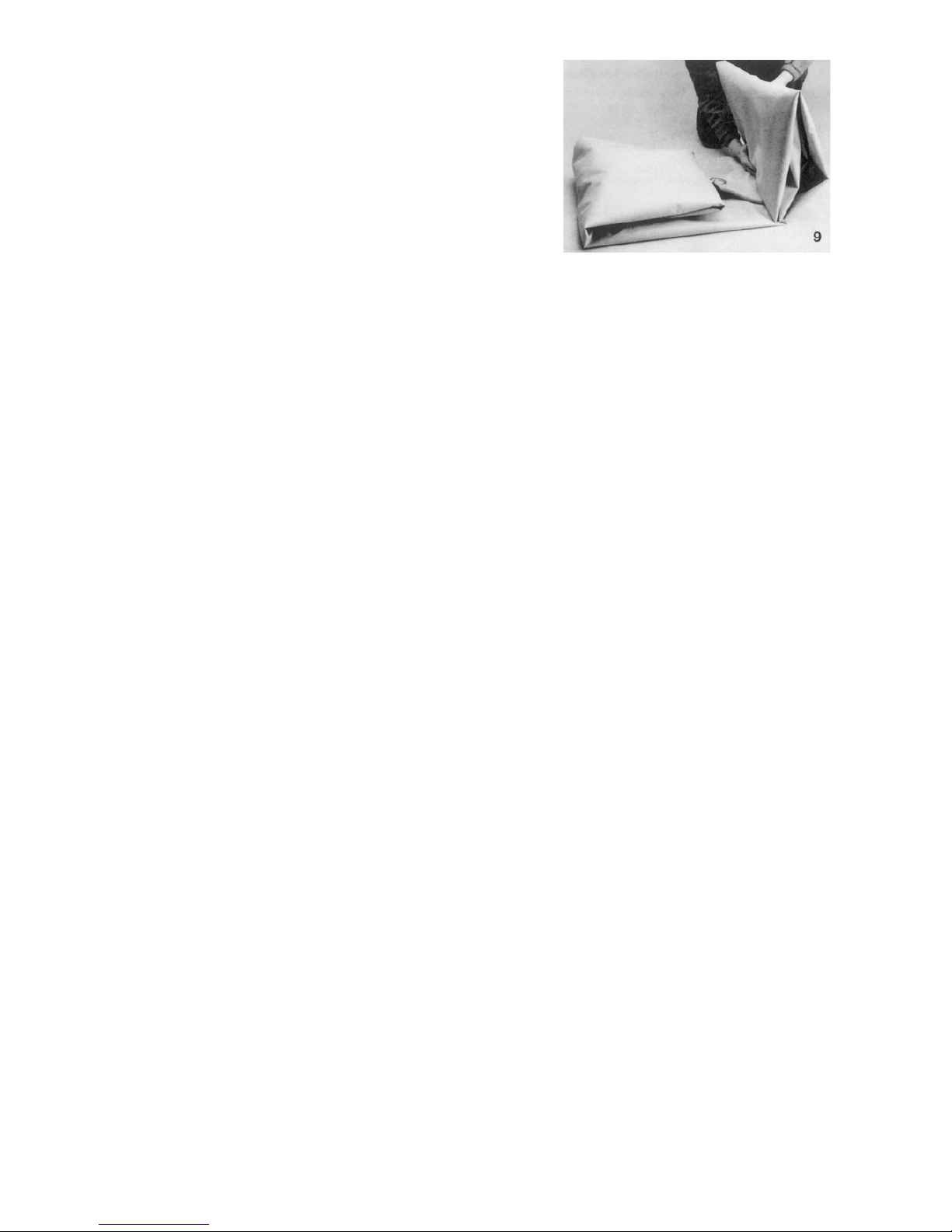

Proper folding of Boat Hull

1.) Lay out hull lengthwise (cockpit facing up) using a sponge, remove

sand and/or water from inside/outside of hull. If required, place rib

(vertical) under bow and stern deck to allow drying of material.

2.) Flatten hull once completely dry and clean, cockpit symmetrically

facing upwards.

3.a) Aerius XXL; II Expedition, Basic II, Magic II with keelstrips,

Quattro :

From the middle of long edge - fold edge of hull lengthwise toward cen-

ter, (approx. 20cm of hull bottom will be visible). Repeat at opposite side

and fold leaving 25cm lower keel protection unexposed.

b.) Aerius I Expedition, Basic I mit Kielstreifen, Aerius Tramp/2000 with

keelstrips Fold long edge toward center on both sides (approx. 20cm of lower hull material will show)

c.) Aerius Classic II (without keelstrips) + Basic II, Magic II without keelstrips Fold lengthwise toward center (both sides) equal

distances.

d.) Aerius Classic I, Basic I without keelstrips und AE Tramp/2000 without keelstrips Fold either side toward almost the cen-

ter of hull - without exposing the center keelstrip.

e.) Alu Lite

Close zipper and velcro enclosure. Fold (lengthwise) to almost halfway point (2 keelstrips are still totally visible).

4.) Flatten hull and remove unnecessary folds.

5.) Grab bow of hull and fold toward center. First folds: 135 cm (AE II) / 105 cm (AE I) / 90 cm (Alu-Lite) and so forth. Fold

this portion again in half to meet in center.

6. a.) Aerius I und Aerius II

Grab stern of hull and fold toward center. fold this portion again in half to meet in center.

b.) Alu-Lite Fold stern portion toward center of hull (approx. 90 cm) repeat folding bow section. Fold balance on top of each

other. Place in bag.

7.) To complete folding procedure, fold each half of folded hull on top of each other - creating a compact package that now

fits into hull carry bag.

How to care for a folding boat:

1) Typical storage:

Short-term or long term, clean and dry, in the packing bags, indoors, in a safe and favourable place. Do not avoid

assembly and take-apart, the more you do it, the easier it gets.

a) After the usual trip, boat would be somewhat wet here and there.Take out the woodwork, prop up front deck and rear

deck with a rib to allow better air circulation. Hull is self-drying, just needs air, little sun a little time.When dry, wipe out

sand and moisture, and take home dry and clean, in your car.

b) If it rains or if it is dark and can not dry outdoors, take it home wet - and in the next few days lay out the hull in backyard,

hallway or basement to let it dry properly. Under tightest conditions: 2 old chairs in small kitchen, lay hull over two chairs,

saves space.

c) Where to store? Usually store in a good section in basement, backroom, shop, or safe garage. Never on cement floor or

wall, always on a chair, carton, shelf, box, off the ground.Avoid extreme wetness or extreme heat. Not so good: in a barn,

woodshed, or open garage, there will be rodents!

d) Taking boat apart allows wood to relax, wood can dry nicely, sand comes out, hull material can dry. The most fastidious

owners keep a hull, gently folded, on a shelf in a dark room, but covered with a bed sheet.

2) Storage of assembled boat:This is not our favoured way to store, but we all do it during a busy season.We do not favor

it, as the assembled boat keeps sand, grit, moisture inside. But, if it suits your purposes, the preferred way is:

a) In basement, shop, garage, on 2 cartons or sawhorses, upside down, cockpit facing floor. Let the air out of sponsons, to

increase air circulation, and as you walk by, slap hull a little, which lets dry sand fall out.

b) Some owners store it „cockpit up, cockpit covered“: fine while on vacation , but long-term, there can be condensation

forming, and sand/grit stays in.

c) If you must keep it outdoors (no other choice), then get it off the ground (upside down) and find a good canvas cover, to

break UV rays. Plastic sticks.

d) If a boathouse is above the water, or next to the water (=high humidity), it would be most helpful to get boat out often

into wind and sun to avoid harm.

Thus: use the boat as much as you want, but keep it safe in long storage periods.Wet storage is harmful to the hull materials,

permanent wetness also causes harm to the wood.