Klimasan R600a User manual

Servicing Coolers Charged with

Hydrocarbon Refrigerants

R600a (Isobutane)

& R290 (Propane)

24 Jan 2014; Version 2

R600a General Specifications

Chemical Formula :C4H10

Effect to Ozone : None

Greenhouse Effect : 3(vs. R134a’s 1300)

Molecular weight : 58,1 kg/kmol (Heavier that air, falls down to ground)

Boiling Temperature : -11,7 °C (It is in the gas form under normal atmospheric conditions)

Critical Temperature : 135 ºC

Critical Pressure : 36.5 Bar

Colour : Colourless

Odour : Odourless

Specifications : Flammable and Explosive

Usage of R600a Gas

As R600a heat transfer coefficient is almost twice that of R134a, for the same cooling output the

R600a amount required will be almost 40 to 45% less than R134a.

The values in right table are given for

approximately comparison. Consider the

values on the product labels for gas charge.

In the systems using R600a gas the suction pressure is below 1 bar (g).

This situation should not be perceived as system blockage.

Different than R134a gas, mineral oil is used, while polyester oil is not used.

R600a gas dissolves in higher rates than R134a gas in mineral oil and its vacuum period is

Lengthier.

Volume R600a R134a R12

50 ml 28 g 62 g 67 g

100 ml 56 g 124 g 135 g

200 ml 113 g 249 g 269 g

500 ml 282 g 622 g 673 g

R600a + mineral oil combination, is less sensitive to paraffinic items than existing

R134a + polyester oil combination, in which we have problems of system blockage.

Therefore, in cooling systems with R600a, the problem of system blockage is less encountered

R600a - Points to Consider

In the cooling systems with R600a and R134a, different compressors are used!

On the compressors in products

where R600a gas is used

there is a flame warning sign

showing that a flammable

and explosive gas is used.

In addition to this flame sign, during the service to the products with R600a, a distinguishing

label/colour etc.is used for recognition of the fact that R600ais used in the product.

During servicing:

Look at the compressor! If you see YELLOW TRIANGLE flame sign, it means that in this

product R600a gas, which is a flammable and explosive gas, is used.

While gas exists in the system, do not approach to the product with any heat sources,

electrical arc sources or welding torch flames; make sure that the heat /flame / electrical arc

sources which are closely located are turned off.

R600a Effects of Overexposure

•Ingestion:

Aspiration Hazard!

•Inhalation:

Inhalation of vapor may produce anesthetic effects and feeling of

euphoria. Prolonged overexposure can cause rapid breathing,

headache, dizziness, narcosis, unconsciousness, and death from

asphyxiation, depending on concentration and time of exposure.

•Skin Contact:

Contact with evaporating liquid can cause frostbite.

•Eye Contact:

Liquid can cause severe irritation, redness, tearing, blurred vision, and

possible freeze burns.

Source: MSDS National Refrigerants / Dec 08

R600a First Aid Measures

Ingestion:

Do not induce vomiting. Contact a physician immediately.

Skin Contact :

For liquid contact, warm areas gradually and get medical attention if there is

evidence of tissue damage. Flush area with plenty of water.

Inhalation:

Remove to fresh air. If breathing has stopped, restore breathing at once.

Administer oxygen and get medical help.

Eye Contact:

For liquid contact, irrigate with running water for minimum of 15 minutes. Consult

physician immediately if frostbite occurs.

Source: MSDS National Refrigerants / Dec 08

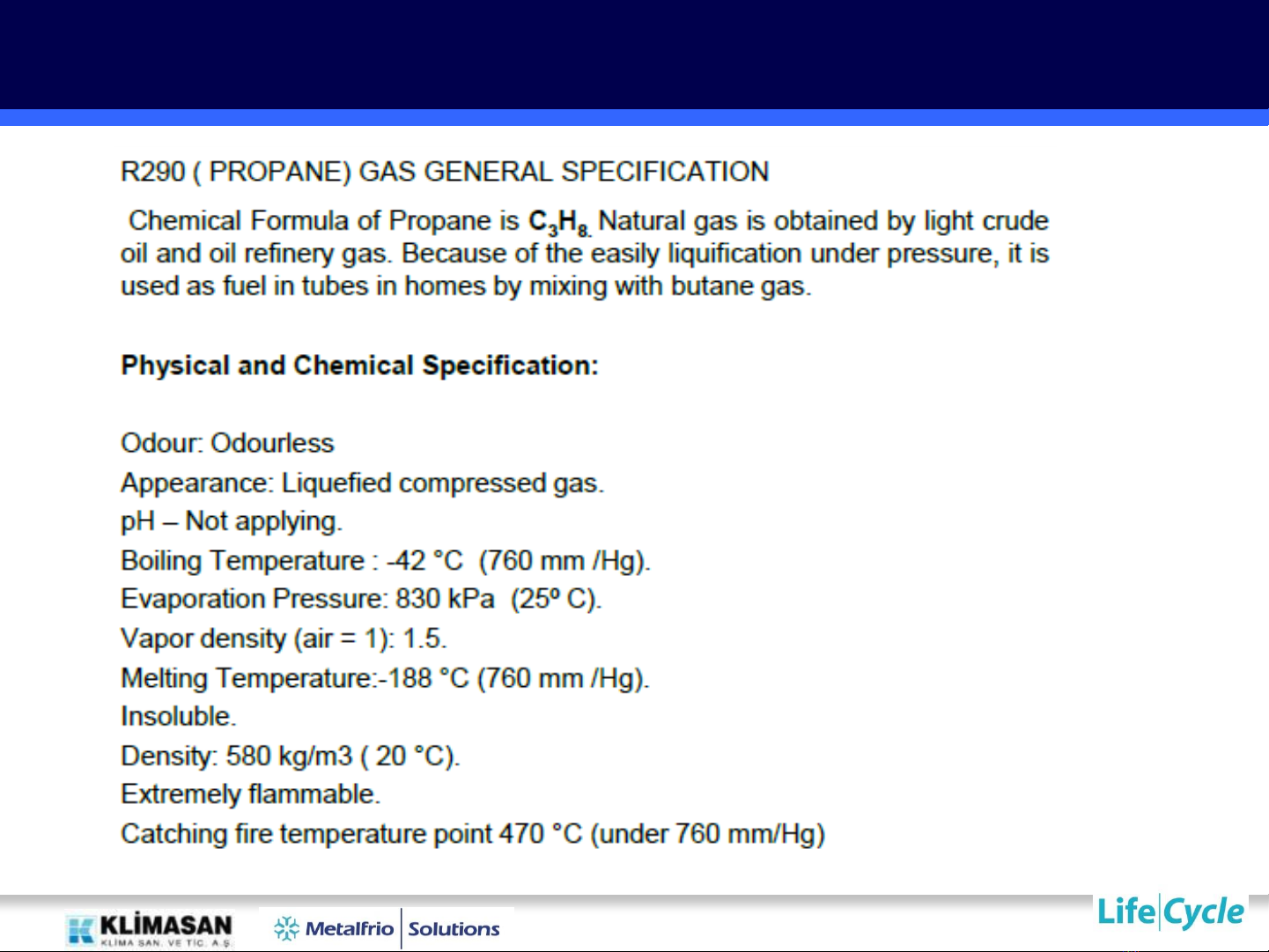

R290 General Specification

R290 Handling & Storage

•Normal Handling:

Keep container closed.

Use only with adequate ventilation.

Keep away from heat, sparks and flame. To avoid fire, minimize ignition sources. Use

explosion-proof electrical (ventilating, lighting and material handling) equipment.

Do not puncture or incinerate container. High pressure gas. Use equipment rated for

cylinder pressure. Close valve after each use and when empty.

Protect cylinders from physical damage; do not drag, roll, slide, or drop. Use a suitable

hand truck for cylinder movement.

•Storage Recommendations:

Keep container tightly closed.

Keep container in a cool, well-ventilated area.

Cylinders should be stored upright, with valve protection cap in place, and firmly

secured to prevent falling or being knocked over.

Cylinder temperatures should not exceed 52°C (125°F).

Source: MSDS National Refrigerants / Dec 08

First Aid Measures for R290

No action shall be taken involving any personal risk or without suitable training. If fumes

are still suspected to be present, the rescuer should wear an appropriate mask or a self-

contained breathing apparatus. It may be dangerous to the person providing aid to give

mouth-to-mouth resuscitation.

Ingestion:

Do NOT induce vomiting unless directed to do so by medical personnel. Never give anything

by mouth to an unconscious person. Get medical attention if symptoms appear.

Skin Contact :

In case of contact, immediately flush skin with plenty of water. Remove contaminated clothing

and shoes. Wash clothing before reuse. Thoroughly clean shoes before reuse. Get medical

attention.

Eyes:

Immediately flush eyes with plenty of warm water for at least 15 min. Get medical attention.

Frostbite:

Try to warm up the frozen tissues and seek medical attention

Inhalation:

Immediately remove to fresh air. If breathing has stopped, give artificialrespiration. If

breathing is difficult, qualified personnel may give oxygen. Get medical attention at once

Source: MSDS National Refrigerants / Dec 08

.

Tips for Proper Use of R600a and/or R290 /1

1. R290 is a very flammable gas like R600a and needs special treatment and

precautions

2. R290 has higher pressure values in the same environment than R600a gas,

so needs to be handled more carefully

3. Because of the R290 is flammable gas like R600, it requires very careful

handling and special security. R290 is more pressurized gas than R600, so

technicians should be more careful

4. Flammable gas mixture, air and ignition source should not be together to

prevent accidents

5. When intervening to a product running with R290 refrigerant, the warning

instructions must be followed properly. They are very similar with the

warnings and instructions for R600a

6. Even though the gas amount seems to be low, flammability and high

pressure factor must be considered always.

7. R600a is used with mineral oil, while R290 is used with ester (polyester) oil.

8. The same driers are being used for R290 and R600a, should have XH-9

Molecular Sieve, check specs before using.

This manual suits for next models

1

Table of contents

Other Klimasan Accessories manuals