PAGE(S) 4 OF

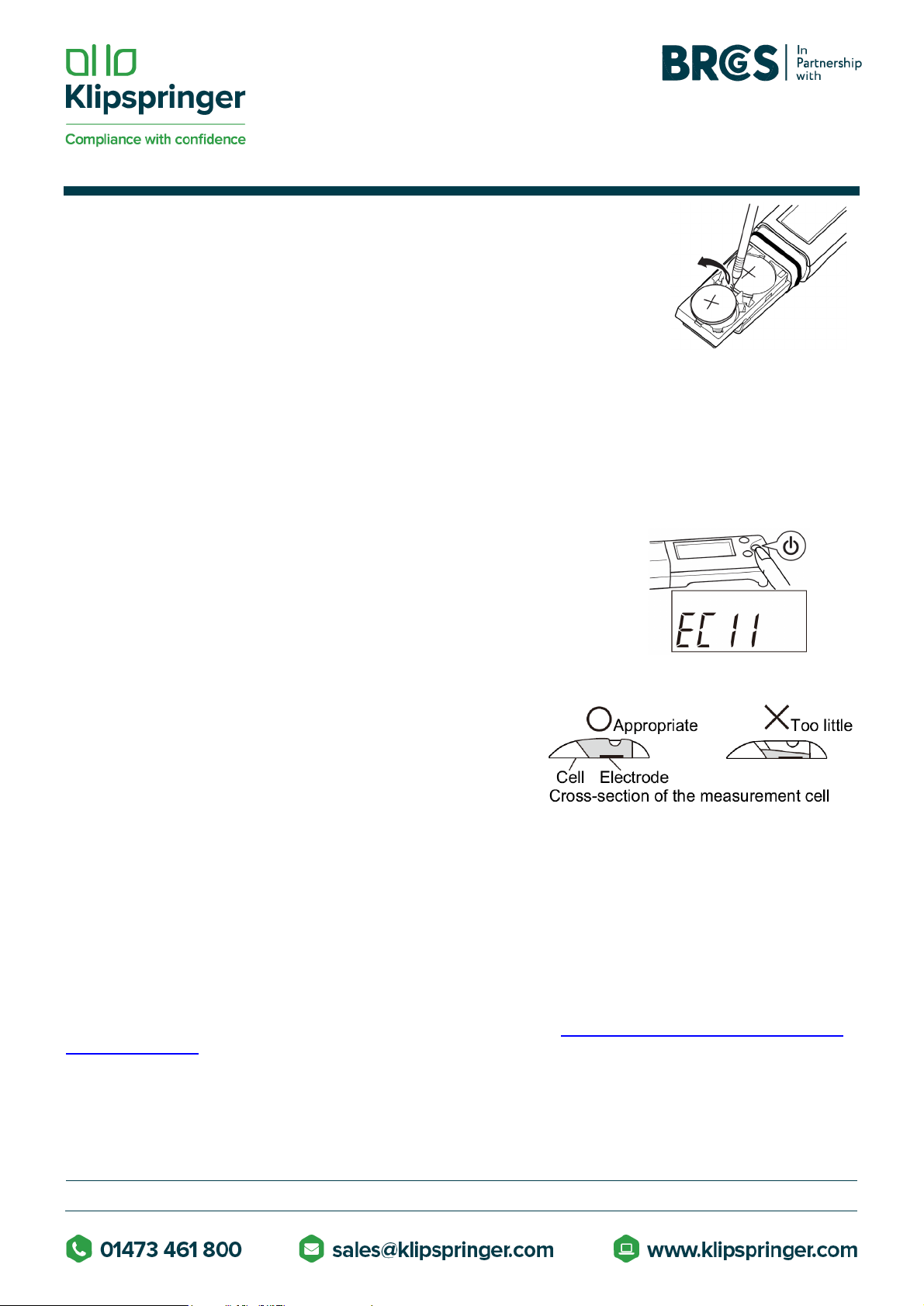

1. Confirm that the meter is in the measurement mode, and place a sample on the sensor.

2. Press the MEAS switch. The auto hold function is activated. blinks until the measured value has

stabilized. When the measured value is stable, stops blinking and the displayed value is locked with and

displayed simultaneously.

3. Document the displayed value.

4. Press the MEAS switch. The auto hold function is deactivated and disappears. Be sure to perform this

step before starting the next measurement. Or, you may mistake the displayed hold value for the next

measured value.

Note: If a measured value is out of the specified measurement range, "Or" is displayed for upper range and "Ur" is

displayed for under range. Ambient air may cause the measured values to fluctuate. To reduce environmental

interference, close the protection cover. When you have a problem with the calibration measurement, refer to

frequently asked questions.

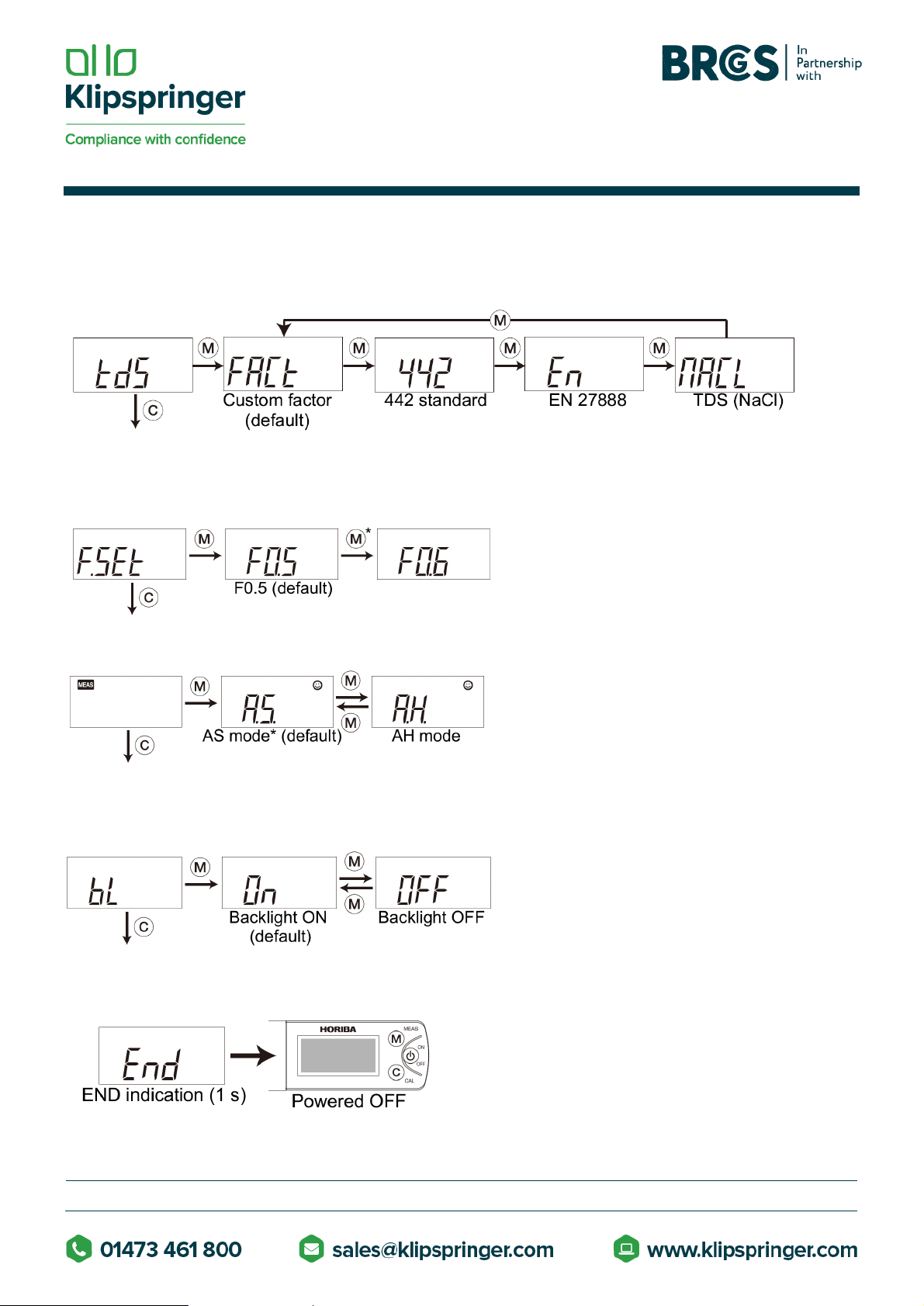

Measurement display change:

Measurement display change is available on PQ0012 and PQ0013. The display mode switches as follows by

pressing the MEAS switch in the AS mode.

•PQ0012: Between conductivity and temperature alternately

•PQ0003: Among conductivity, TDS, and temperature

Maintenance

Storage:

1. Clean the sensor with tap water.

2. Dab gently with soft tissue or cloth to remove moisture on the sensor and meter.

Note: Especially be sure to treat the sensor gently to prevent damaging it.

3. Close the protection cover before storing the meter.

Temperature sensor adjustment:

Temperature sensor adjustment is available on PQ0012 and PQ0013. To perform accurate measurement with

correction for temperature effects, follow the steps below. Normally this is not necessary.

1. Ready a reference thermometer, and allow the meter and reference thermometer to reach to room

temperature.

2. Set the display mode to temperature referring to " Measurement display change" (page 2).

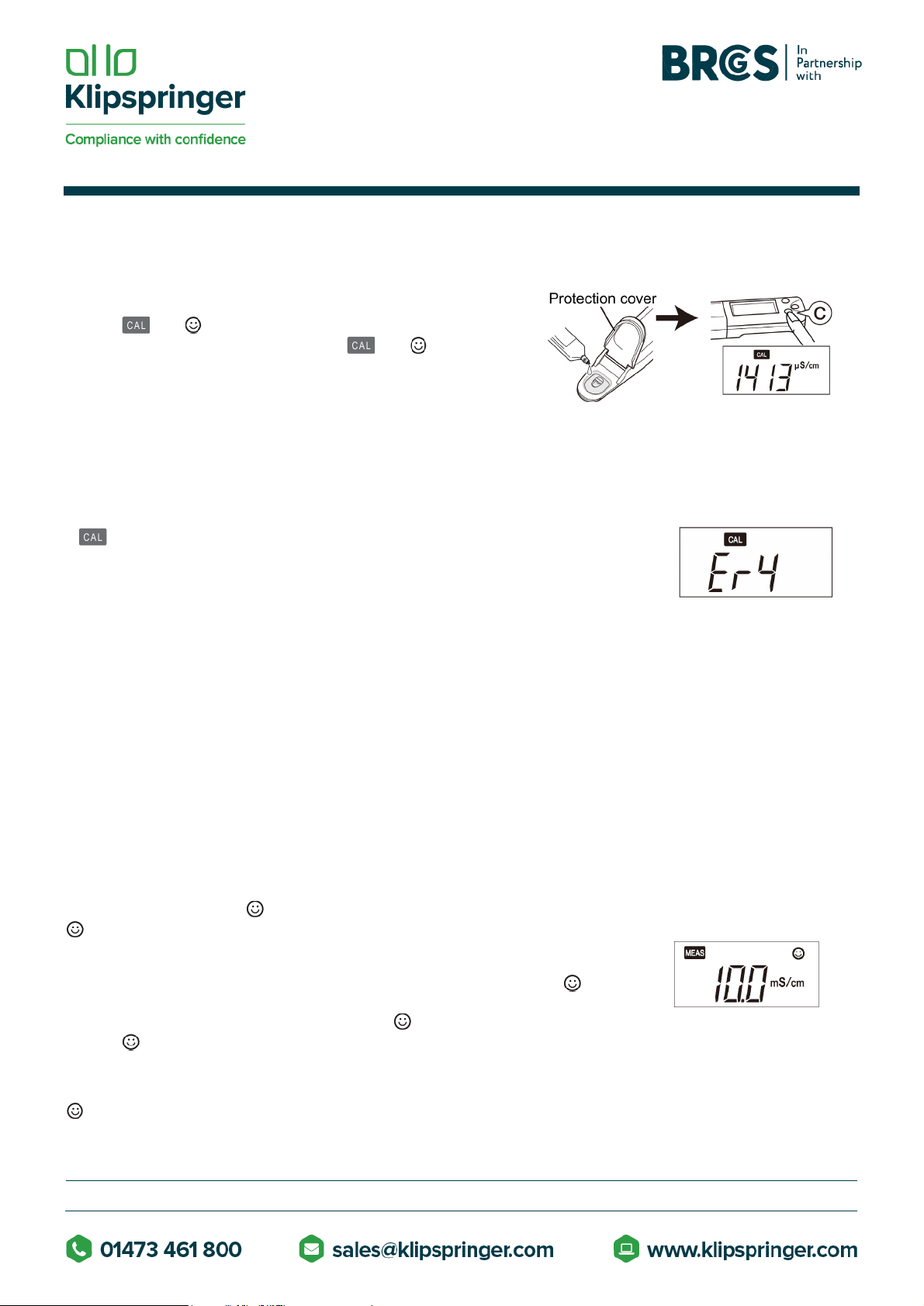

3. Press the CAL switch. The meter displays the setting screen for target temperature.

4. Press the MEAS switch to adjust the displayed temperature on the meter to match the temperature

indicated by the reference thermometer. Pressing the MEAS switch increases the displayed

temperature. After the displayed temperature reaches 400C, it returns to 50C.

5. Press the CAL switch again to apply the displayed value to the adjustment. The adjustment starts.

The adjusted value blinks with and °C displayed. After the adjustment is complete, the adjusted value stops

blinking with MEAS and °C displayed. If Er4 (error display) appears, the adjustment has failed. Retry the

above steps increasing the time spent on the step 1. If the adjustment repeatedly fails, the sensor may

have deteriorated. Replace the sensor with new one.

Initializing calibration data:

Initialize calibration in the following cases:

•To delete the calibration data