M

cross-section

side view

2 cm

L L M

B

K

M

L

M

L

B

A

E E

cross-section

side view

cross-section

side view

E F

I I

I I

E

F F

I I

I

I

R

D

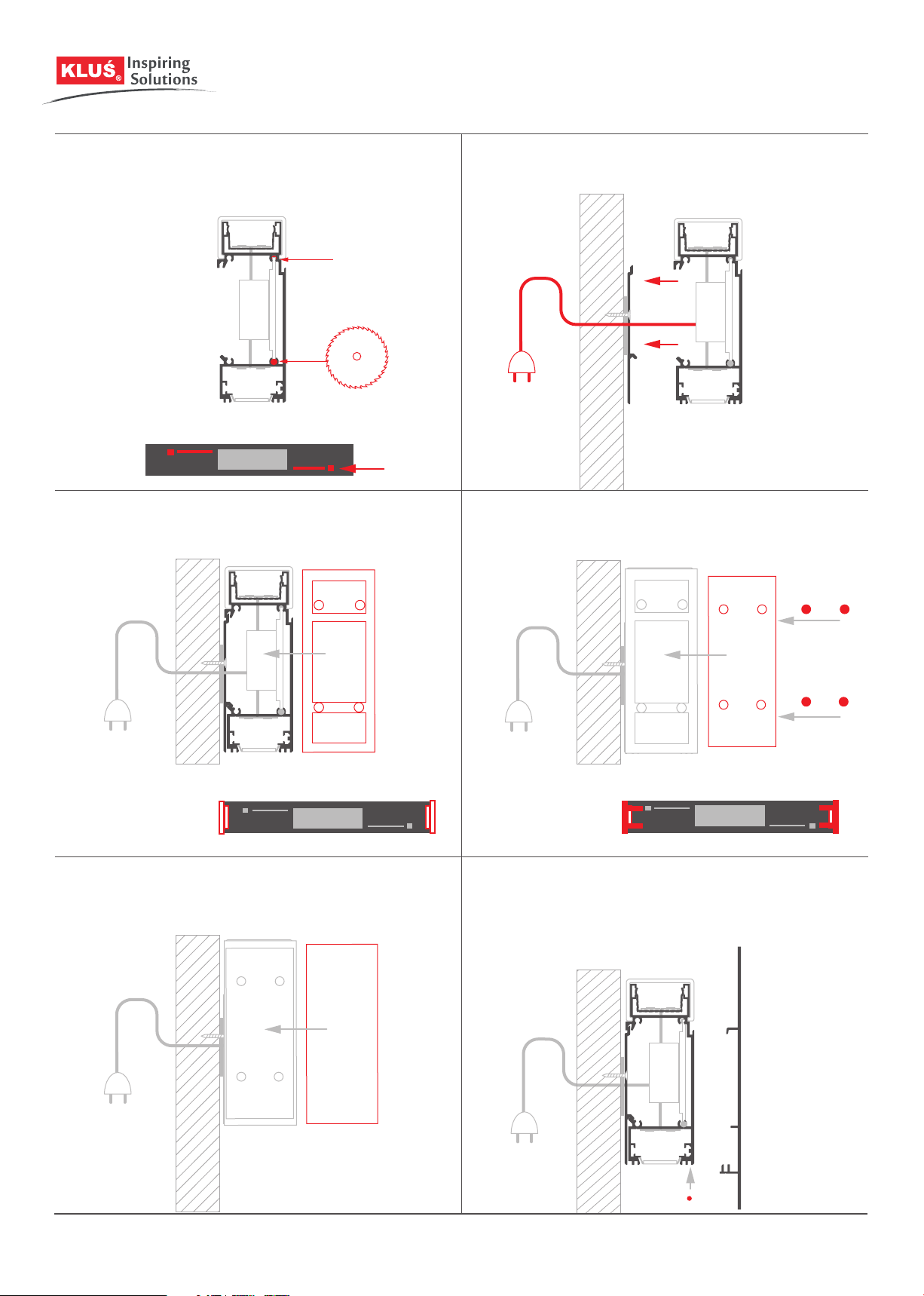

7. Secure the power supply bracket (K) by inserting one 2.4mm plastic rod

(L) into the guides on each side. Cut the rods to the required length. Next

secure the rods with M3 pressure screws (M), tightening them with the Allen

wrench to a min. depth of 2 cm.

8. Connect power and assemble the extrusion (B) with the mounting strip (A).

9. Insert the gaskets (E). 10. Insert the brackets (F) into the hollows of the gaskets (E) and mount

them with bolts (I).

11. Insert the masking cover (G) into the collar of the gaskets (E). 12. Install springs (R) in the marked groove (minimum two per meter)

where the lower hook of the decorative cover (D) is going to mount. The

number of springs should be: 2 for 1-meter long proles, 3 for 2-meters long

proles and 4 for 3-meters long proles. First and last spring should be placed

10-15 cm from the end of the prole.

KIDES-DUO mounting instructions

3

www.klusdesign.eu