4

Intended Use

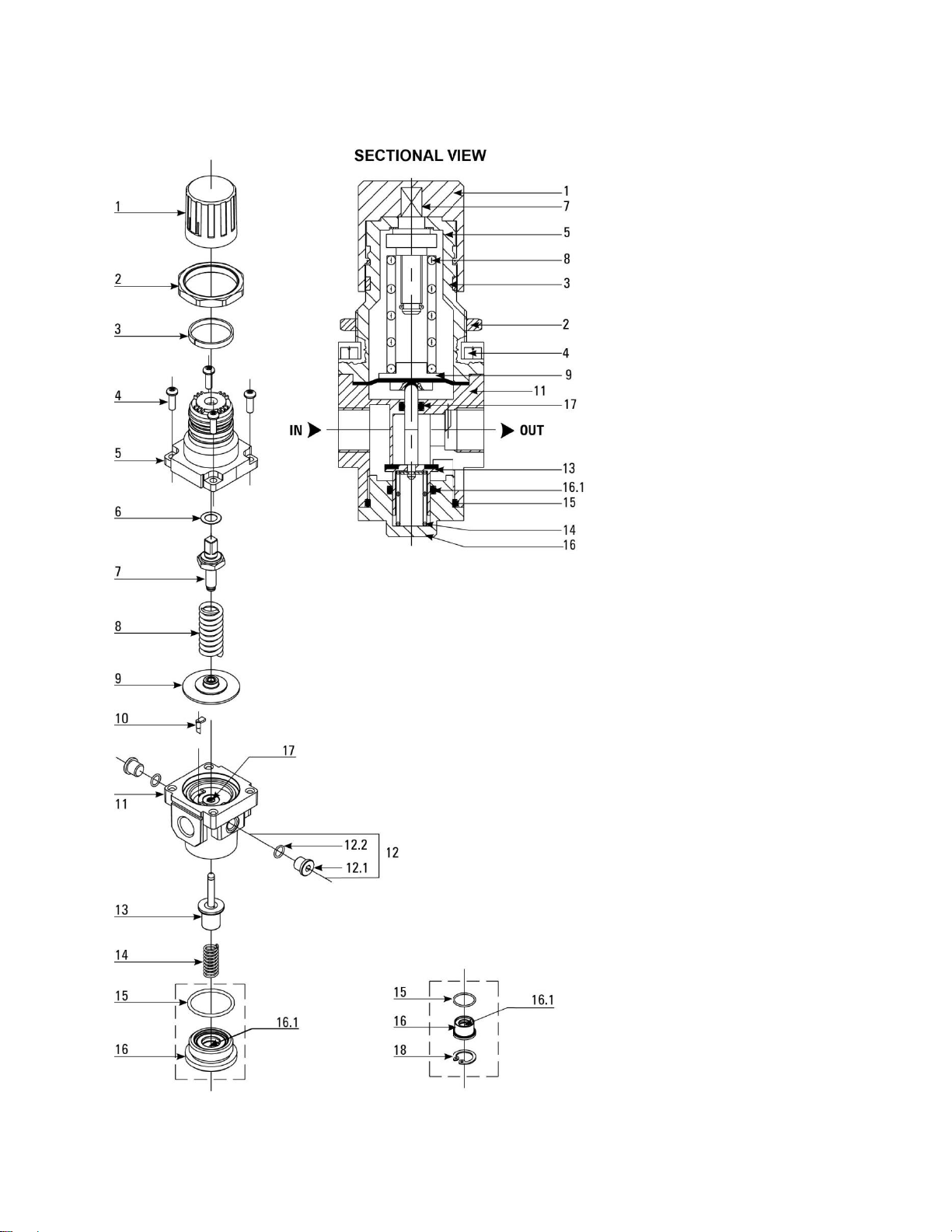

•The Klutch Filter Regulator and Lubricator is one of the most popular air preparation units. The

regulator and lubricator are assembled together to form a single unit.

•The air filter is used to separate dust, dirt, moisture, and other contaminants from compressed air.

•The filter has a die-cast aluminum body, polycarbonate bowl with a steel bowl guard, and a high

performance sintered bronze filtering element.

•Filter is designed with a Separator and Shield for efficient moisture separation. It is combined with

a Regulator which maintains a steady outlet pressure, unaffected by variations/fluctuations in the

inlet pressure.

•The Filter Regulator and Lubricator has a non-raising, press-to-lock adjusting knob for locking at

any set pressure. The Filter Regulator and Lubricator works on a diaphragm-operated, relieving

mechanism with pressure compensated by a balanced poppet.

•Air lubricators are used to feed lubricants to pneumatic equipment. These maintain a constant oil-

to-air density over a wide range of flow.

•The lubricator has fog/micro misting abilities, up to 50-foot pipe runs.

•The head is fitted with an oil drop indicator, an oil drop controller, and an oil filling plug.

•A 1/8” mechanical air pressure gauge is included.

WHY USE A FILTER?

•The air being supplied to the equipment may contain moisture, dust, dirt, or other foreign particles

which can damage the equipment. To prevent damage, install a filter before the equipment.

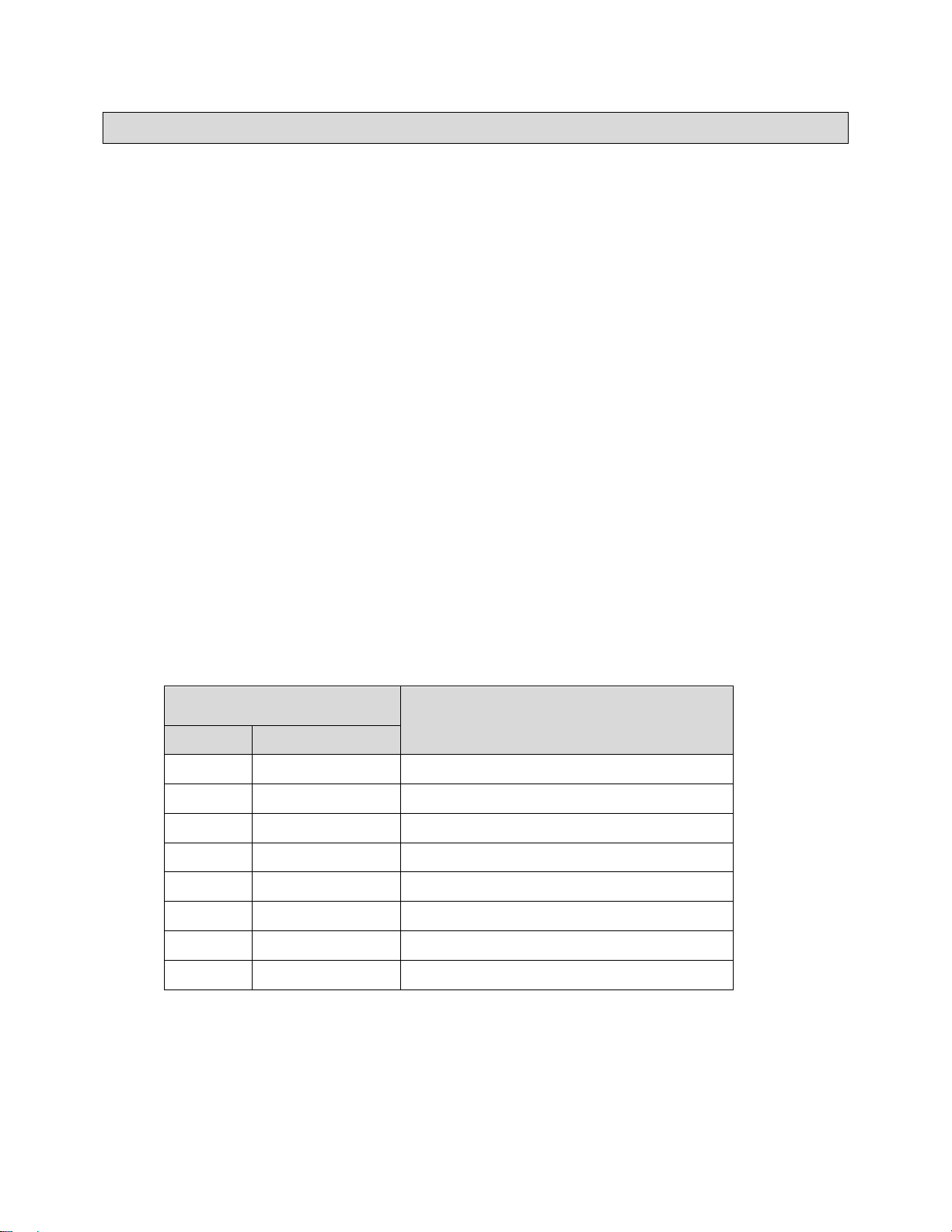

GENERAL SELECTION GUIDE FOR CHOOSING THE CORRECT FILTER BASED ON COMPRESSOR

SIZE