SECTION 1

INTRODUCTION

Jan 2001 Page 1-1 05114566

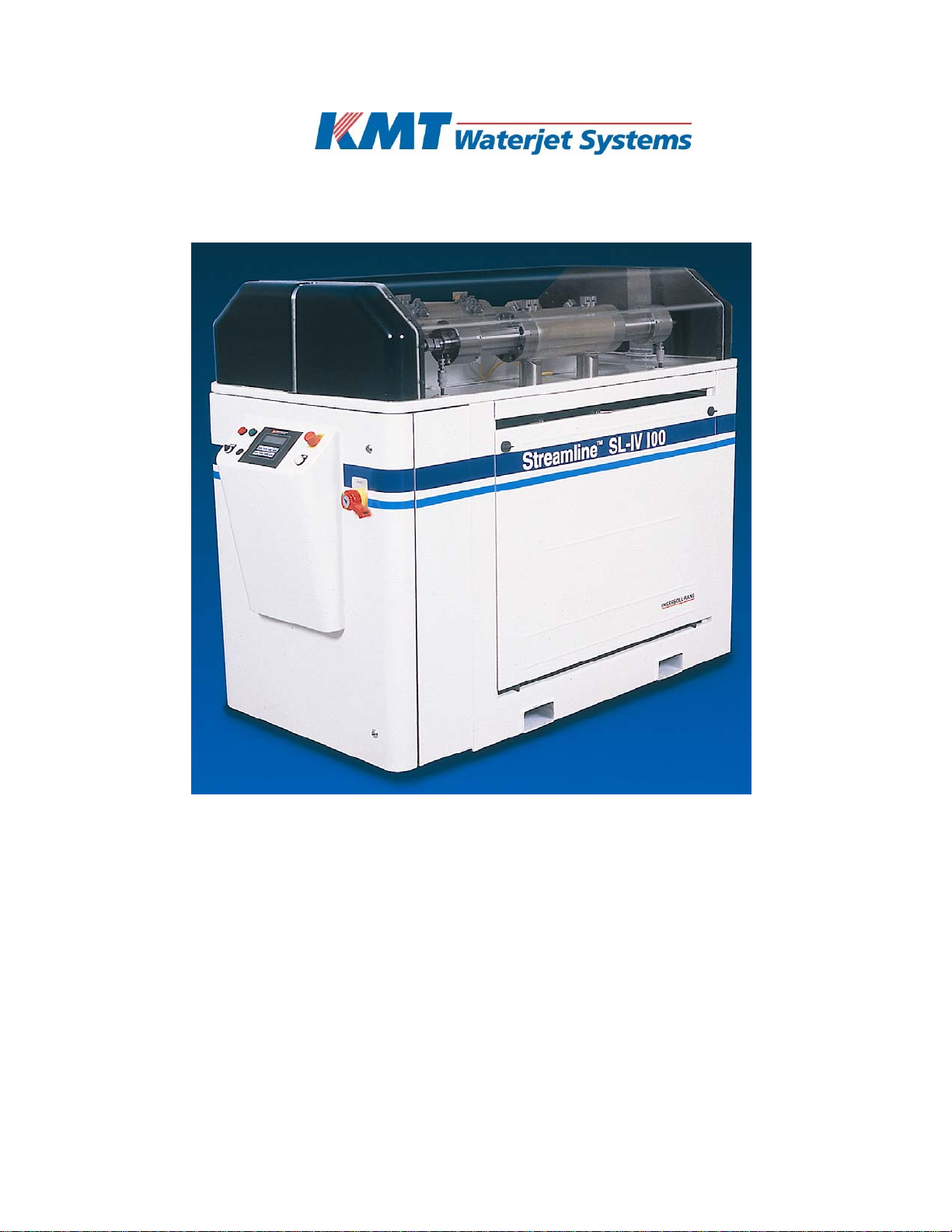

1SL-IV 100hp Waterjet Pump General Information

The Streamline SL-IV 100hp Waterjet Pump, maintains the level of component

reliability and ease of installation and maintenance that have made the KMT

Waterjet Streamline waterjet pumps the standard of the industry for both water

and Hydrobrasive™ applications.

The SL-IV 100hp Waterjet Pump uses low pressure water, which meets certain

quality requirements, and increases the pressure up to 3,800 bar (55,000 psi)

for ultra-high–pressure waterjet cutting, hydrobrasive cutting, cleaning, surface

preparation, etc.

This manual provides information for installation, operation, and maintenance

of the SL-IV100hp Waterjet Pump.

1.1 Physical Description

The 100hp waterjet pump is equipped with two simultaneously operating

hydraulic intensifiers, two high pressure attenuators, a motor/hydraulic pump

assembly, an electric starter panel, control sensors, solenoids and logic, control

interface panel, a low pressure water boost pump, and a low pressure water

filter.

It is enclosed in a frame with the dimensions of 77.75” length, 36.0” width, and

56.19” height. The high pressure system is conveniently mounted on a drip

pan. All service components are easily accessible from at least two sides

simplifying maintenance. The entire high pressure system can be removed from

the rest of the unit quickly for maintenance and serviceability.