10

3 Safety

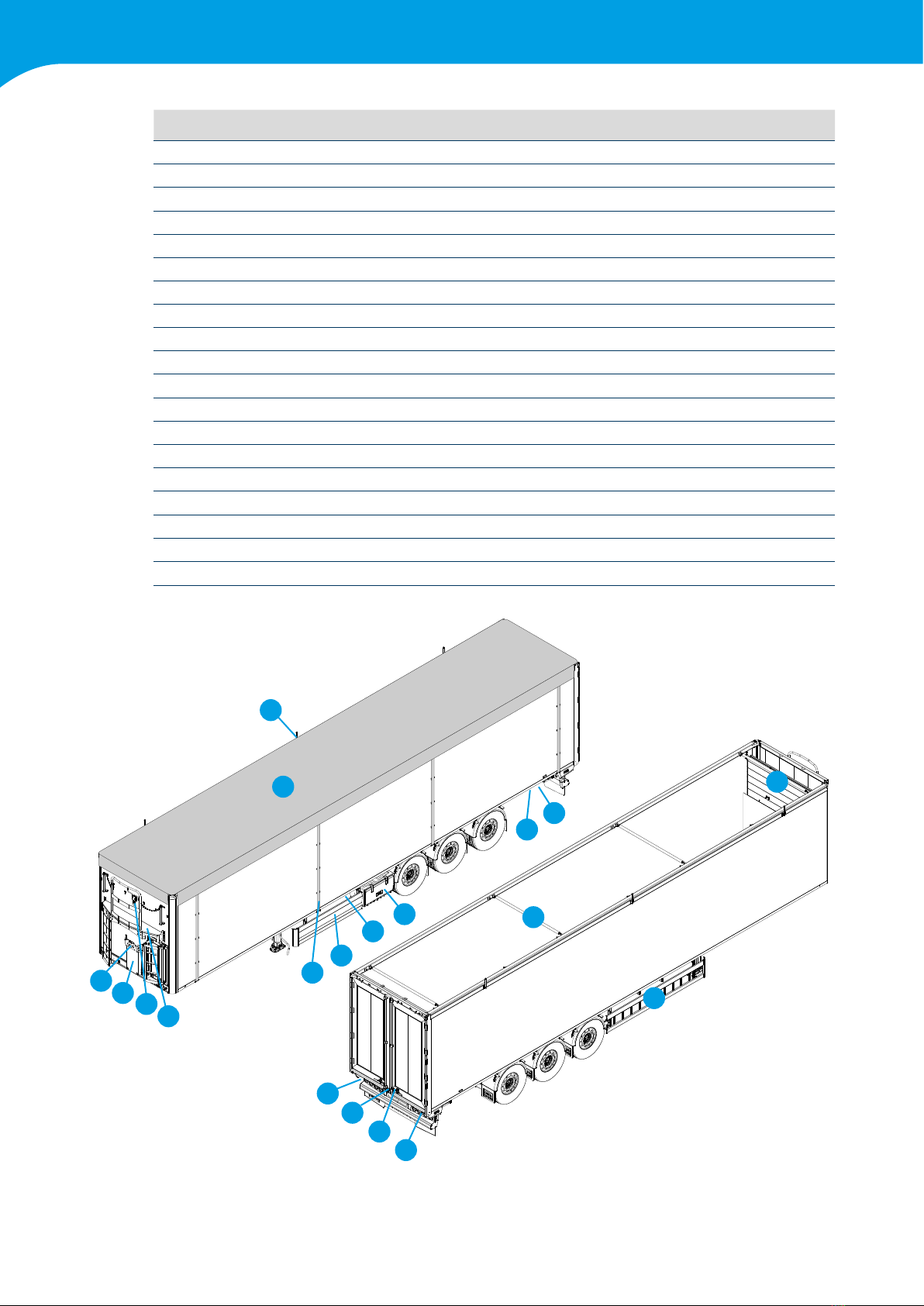

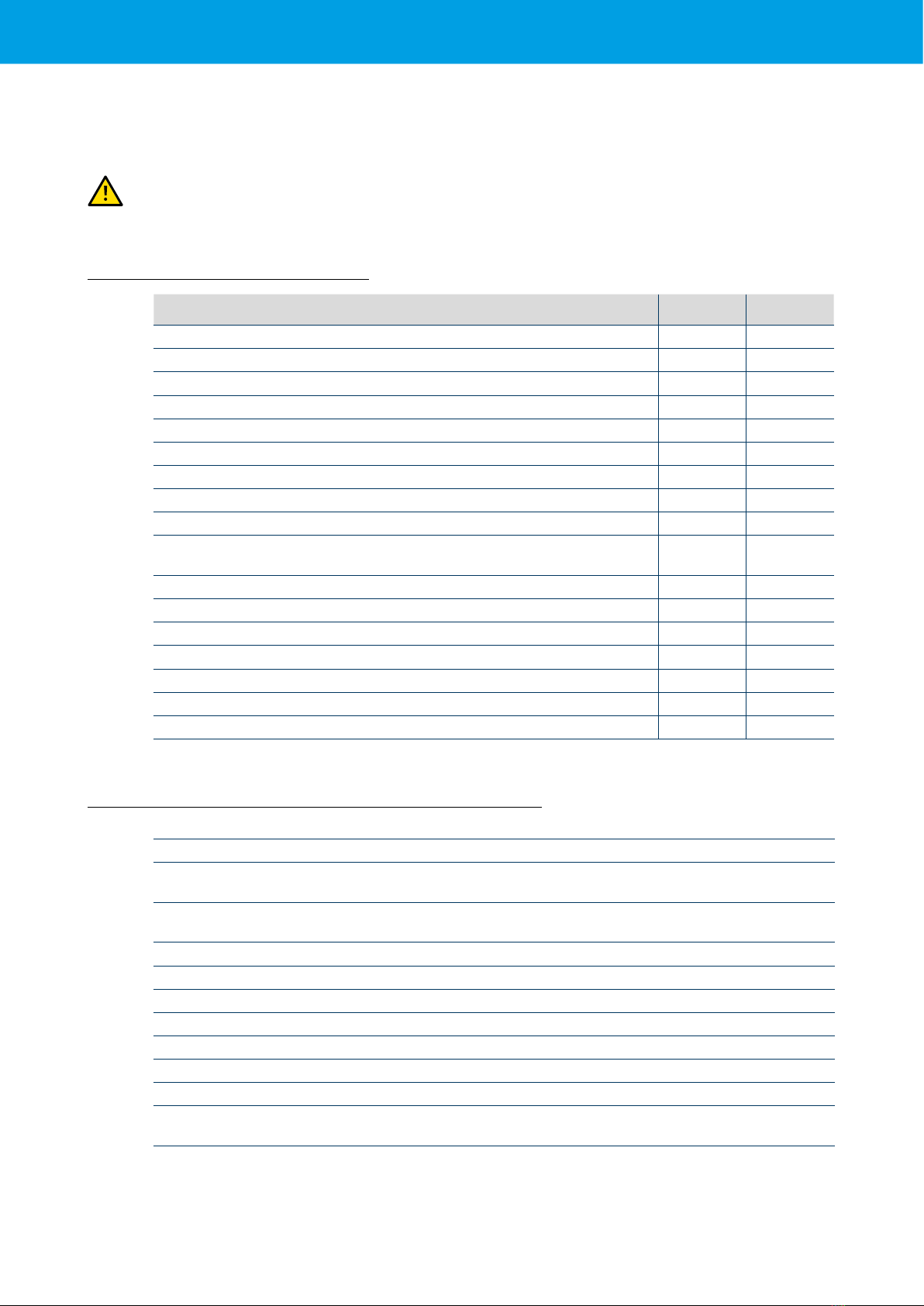

3.3 Standard visual inspection before driving off

The visual inspection prior to driving off is very important for the safety of the driver, bystanders, and fellow

road users.

Points for attention are:

Istheairsuspensionindrivingposition?

Istherehydraulicoilleakage?

Isthereanaudibleairleak?

Arealltoolssuchasladders,etc.,properlysecured?

Arethedoorsclosedandisthepneumaticdoorlockingdeviceswitchedon?

Isthesheetingsystemclosed?

Isthelightingvisible(protectionplatefoldedup),doesthelightingworkproperlyandisitclean?

Dothetyreshavethecorrectpressureandaretheyingoodcondition?

Aretheairbagsundamaged?

Isthelicenseplateproperlylegible?

Aretherenoloosepartsorothercircumstancesthatarenot"correct"?

Checktheconnectionbetweenthealuminiumoorboardsandtheoorsystemfortightnessoftheoorbolts.

Thischeckmusttakeplaceaftertherstloading/unloading,afterapproximately10timesloading/unloading

andafteramonth.Iftheboltmountingoftheoorplanksisnotcorrect,adifferencewilloccurintheforces

transmittedtotheoorsystembytheoorplanks,whichinturncanleadtodamagetothedriveunit.

Checking the oor plank mounting

Switchonthemovingooratnormalspeed.Placea

ngeronthetransitionbetweenthecountersunkbolt

andoorplankIftheboltisloose,youwillnoticethis

assoonastheoorplankmoves.

Replace the bolts if there is play. Check this a few days

afterreceivingthesemi-trailer,aftertenloadings/

unloadings and after one month.

Specication bolts oor plank

M12x30countersunkboltwithhexagonsocketcl.10.9galv.counters.DIN7991.

ApplyLoc-titetothebolts(Loc-tite®243cat.o.23286thread-locker).

The tightening torque is 140 Nm.

Attention: if a oor bolt is loose, there is no point in just tightening it again.

The bolt will become loose again and may cause damage to the system.

What to do with loose bolts

Completely remove the loose bolt and clean the cone of the mounting hole as well as the underlying thread. Mount

anewM12x30class10.9bolt,completelygrease-free,withLoc-tite(Loc-tite®243cat.o.23286thread-locker).

The tightening torque is 140 Nm.