Contents

Introduction.................................................................2

Safety...........................................................................4

SafeOperatingPractices.......................................4

Supervisor’sResponsibilities.................................4

BeforeOperating.................................................4

WhileOperating...................................................5

Maintenance.........................................................6

SoundPressureLevel...........................................7

VibrationLevel.....................................................7

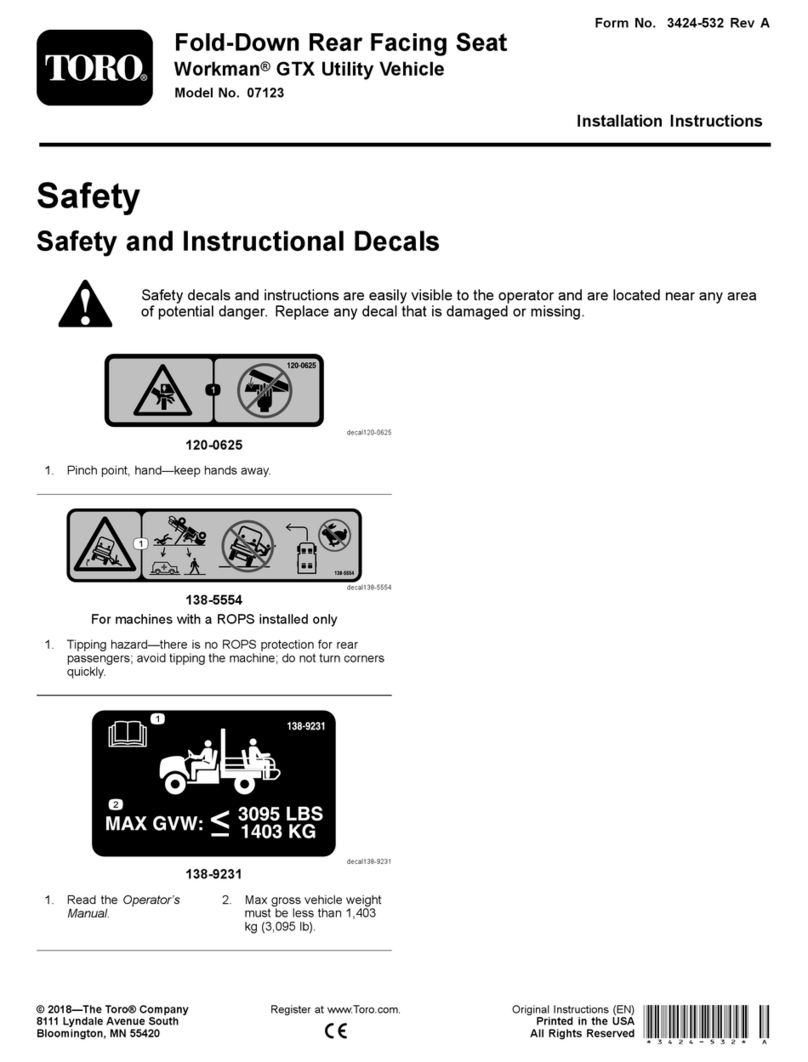

SafetyandInstructionalDecals.............................7

Setup..........................................................................13

1InstalltheRearFenders....................................13

2InstalltheWheels............................................14

3InstalltheSteeringWheel.................................14

4InstalltheFrontFenders..................................15

5InstalltheROPS..............................................15

6ActivateandChargetheBattery........................16

7FullBedRemoval.............................................17

8Re-InstalltheFullBed......................................18

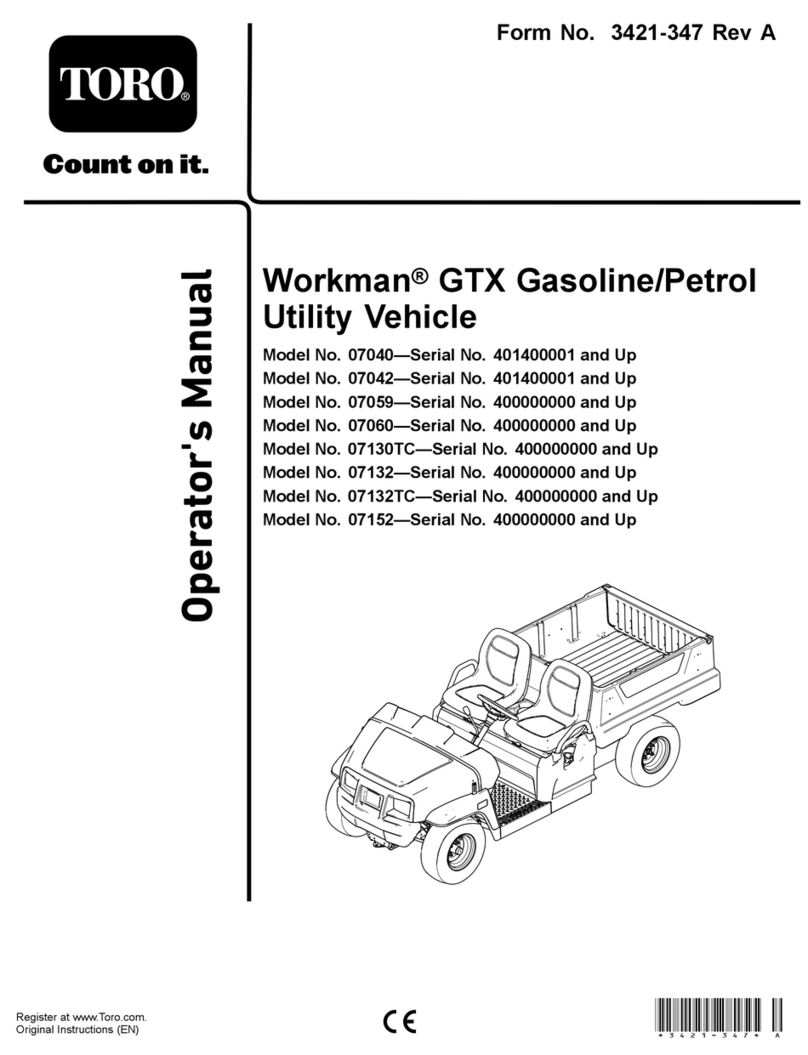

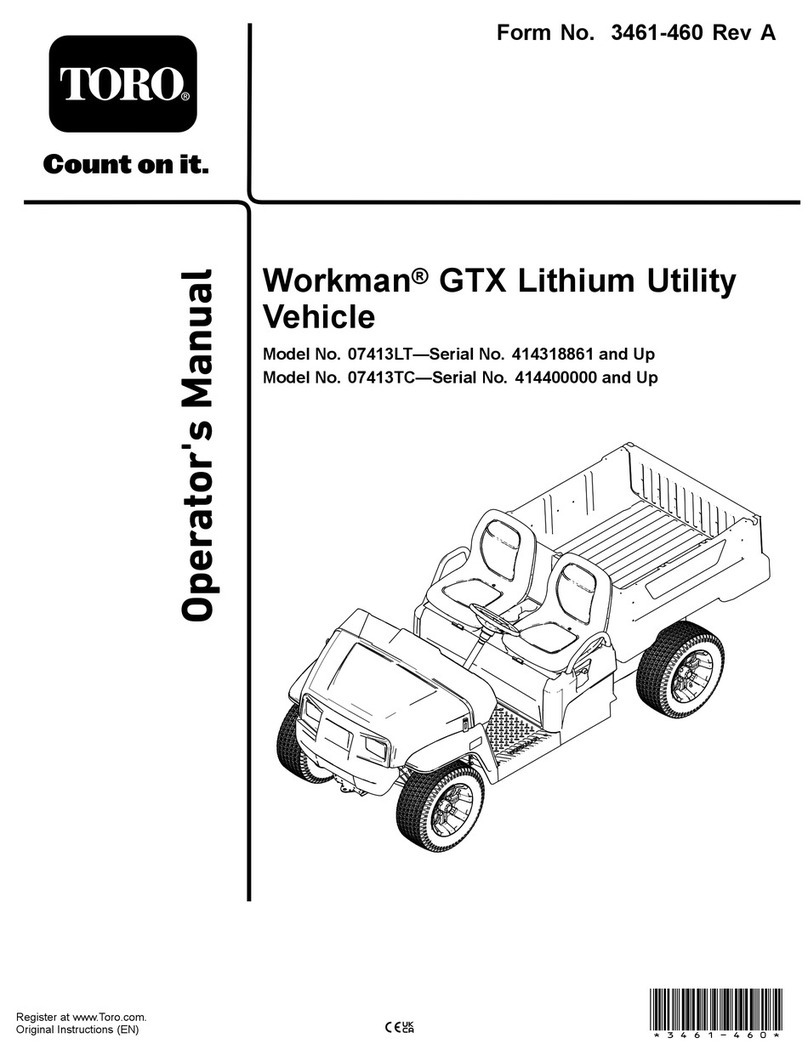

ProductOverview......................................................19

Controls.............................................................19

Specications.....................................................22

Attachments/Accessories...................................23

Operation...................................................................23

CheckCrankcaseOil..........................................23

FillFuelTank.....................................................24

CheckCoolingSystem........................................25

CheckTransaxle/HydraulicFluid......................25

CheckFrontDifferentialOil...............................26

CheckTorqueOfWheelNuts.............................26

CheckTirePressure............................................26

CheckBrakeFluid..............................................26

CheckFanBeltTension......................................27

Pre–startingChecks............................................27

StartingEngine...................................................27

DrivingVehicle..................................................28

StoppingVehicle................................................28

StoppingEngine.................................................28

NewVehicleBreak–in........................................28

CheckInterlockSystem......................................28

OperatingCharacteristics...................................29

Passengers..........................................................30

Speed.................................................................30

Turning..............................................................30

Braking..............................................................30

Tipovers.............................................................31

Hills...................................................................31

LoadingAndDumping.......................................32

UsingTheDifferentialLock...............................32

FourWheelDrive...............................................33

TransportingVehicle..........................................33

TowingVehicle...................................................33

TrailerTowing....................................................33

HydraulicControl...............................................34

Maintenance...............................................................36

RecommendedMaintenanceSchedule(s)................36

ServiceIntervalChart.........................................37

HeavyDutyOperation.......................................37

PremaintenanceProcedures....................................38

UsingBedSafetySupport...................................38

JackingVehicle...................................................39

Lubrication.............................................................39

GreasingBearingsandBushings.........................39

EngineMaintenance...............................................41

GeneralAirCleanerMaintenance

Practices.........................................................41

ServicingAirCleaner..........................................41

ChangingEngineOilAndFilter..........................41

ReplacingSparkPlugs.........................................42

FuelSystemMaintenance.......................................43

FuelSystem........................................................43

ElectricalSystemMaintenance................................43

Fuses..................................................................43

JumpStartingVehicle.........................................44

BatteryCare.......................................................44

DriveSystemMaintenance.....................................45

ChangeFrontDifferentialOil.............................45

InspectConstantVelocityBoot...........................45

AdjustingShiftCables........................................45

AdjustingHigh–lowCable..................................45

AdjustingDifferentialLockCable.......................45

InspectTires......................................................46

FrontWheelToe................................................46

CoolingSystemMaintenance..................................47

RemovingDebrisFromEngineCooling

System............................................................47

ChangingEngineCoolant...................................47

BrakeMaintenance.................................................49

InspectBrakes....................................................49

BeltMaintenance....................................................49

AdjustingBelts...................................................49

ControlsSystemMaintenance.................................50

AdjustingAcceleratorPedal................................50

AdjustingBrakePedal.........................................51

AdjustingClutchPedal.......................................51

AdjustingParkingBrake.....................................52

HydraulicSystemMaintenance...............................53

ChangingTransaxle/HydraulicFluid.................53

ReplacingHydraulicFilter...................................53

CleaningHydraulicStrainer................................54

EmergencyBoxRaising......................................54

Storage.......................................................................56

BatteryStorage...................................................56

Schematics.................................................................57

3