Introduction

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comfor

productandaccessoryinformation,helpndingadealer,

ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.

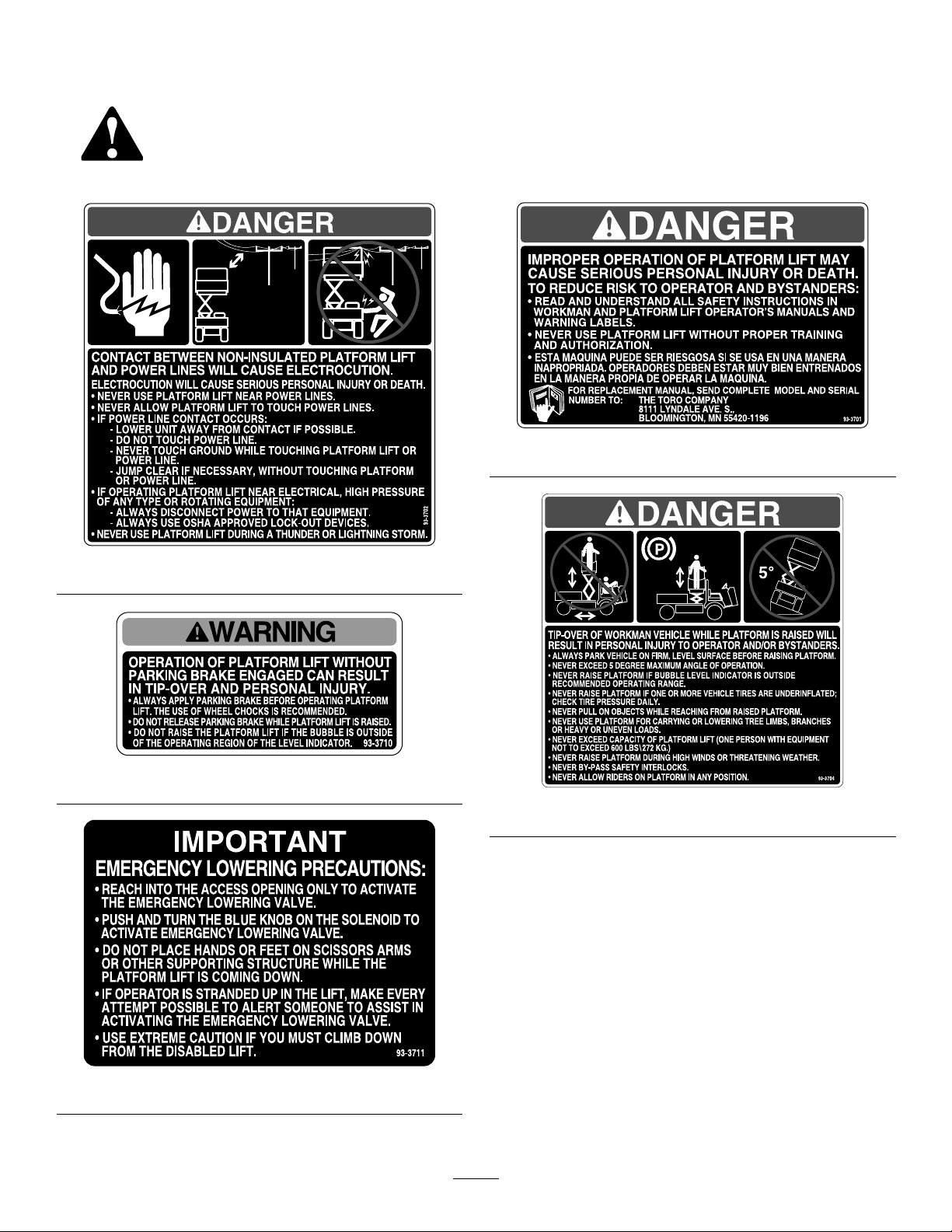

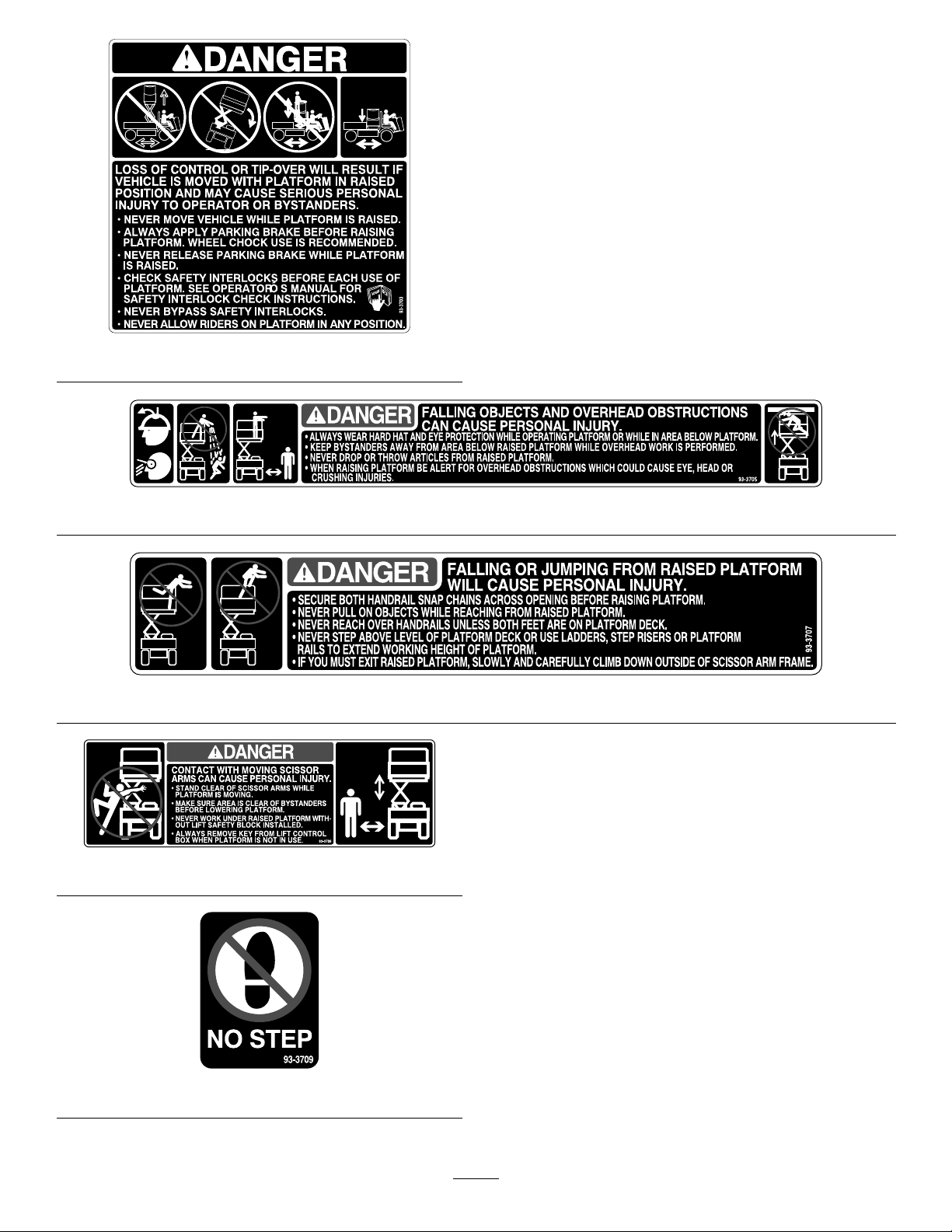

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure1),

whichsignalsahazardthatmaycauseseriousinjury

ordeathifyoudonotfollowtherecommended

precautions.

Figure1

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Introduction.................................................................2

Safety...........................................................................3

BeforeOperating.................................................3

WhileOperating...................................................3

Maintenance.........................................................3

SafetyandInstructionalDecals.............................4

Setup...........................................................................6

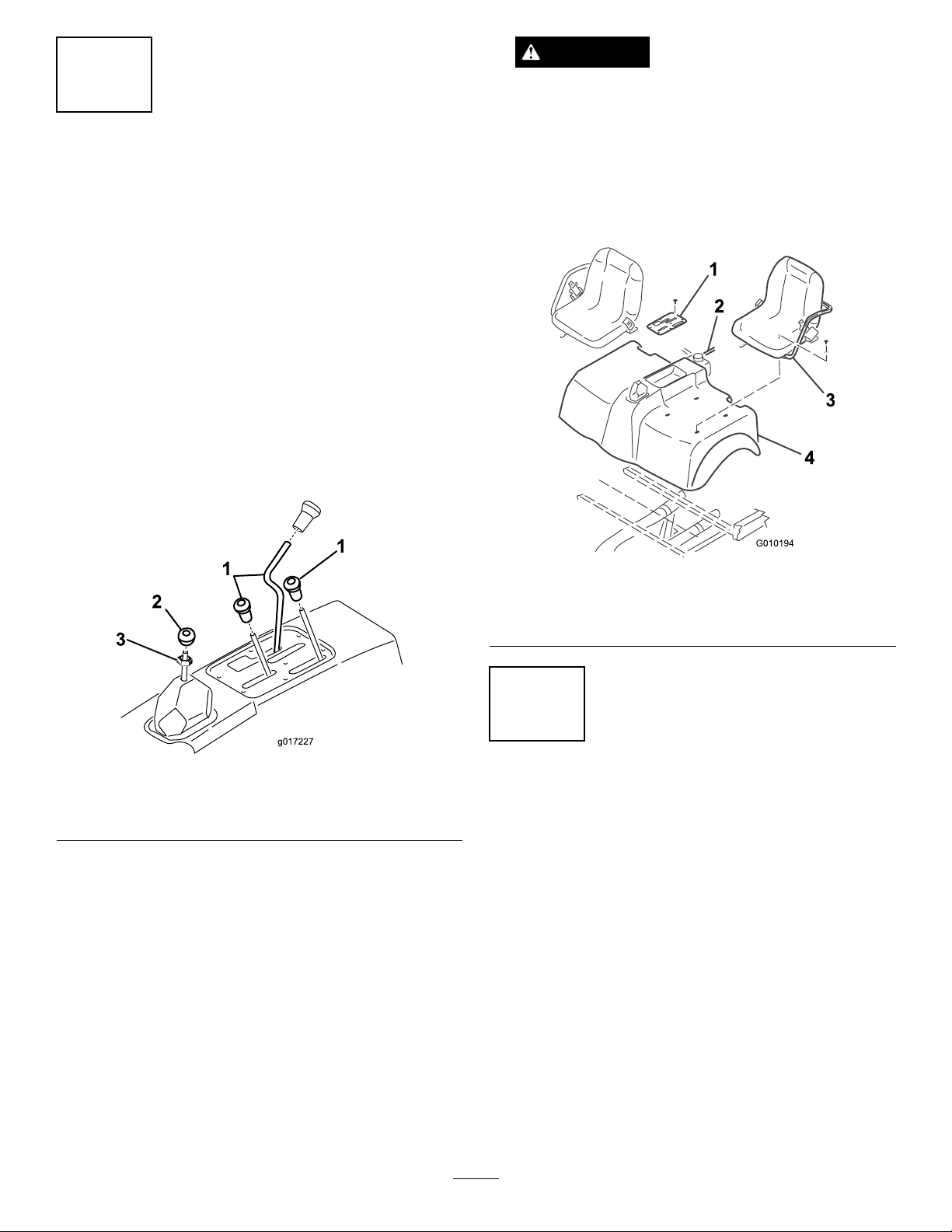

1RemovetheSeat,ShroudandFender

Assemblies.......................................................7

2RemovingtheHood..........................................7

3InstalltheMainWireHarnessw/Relays..............8

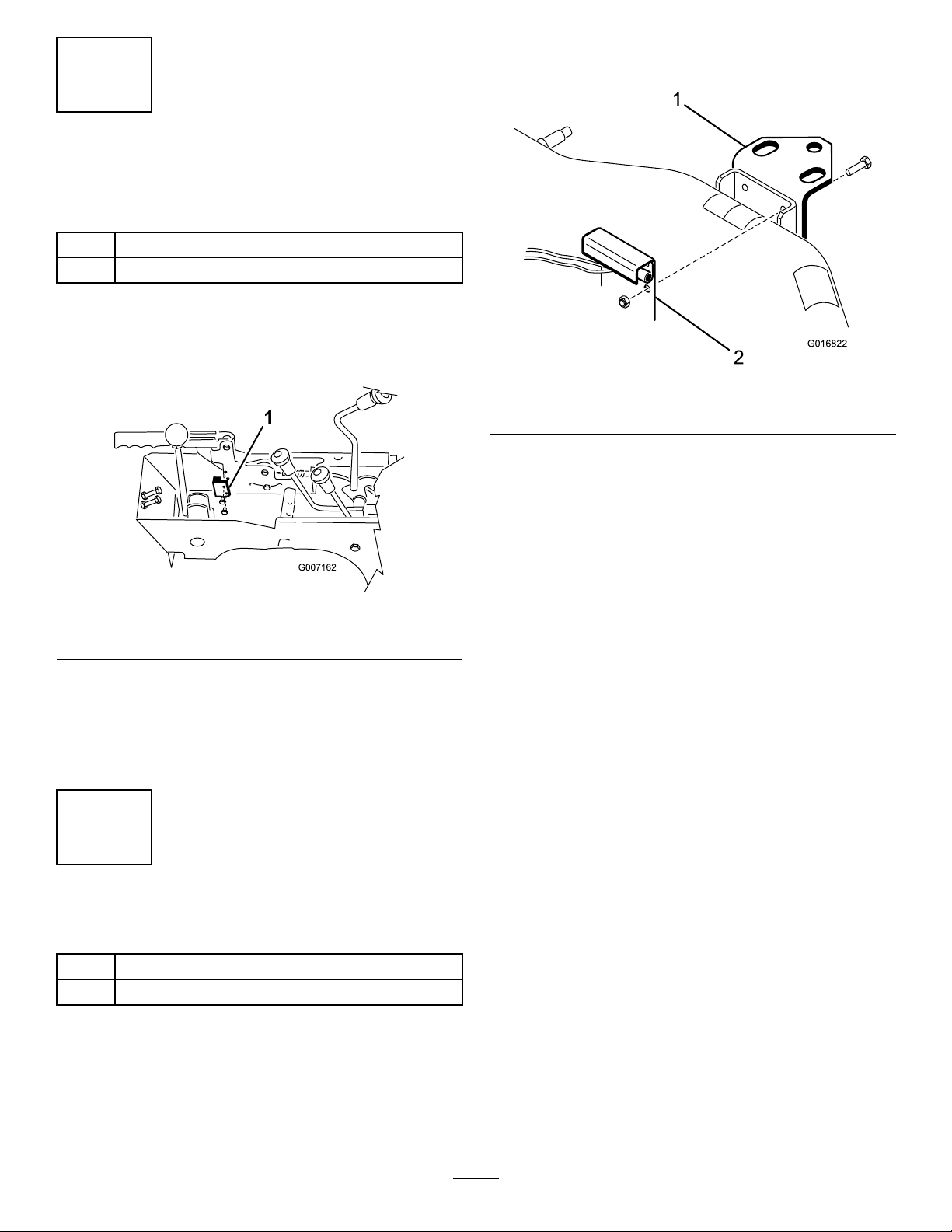

4MounttheParkingBrakeSwitch.........................8

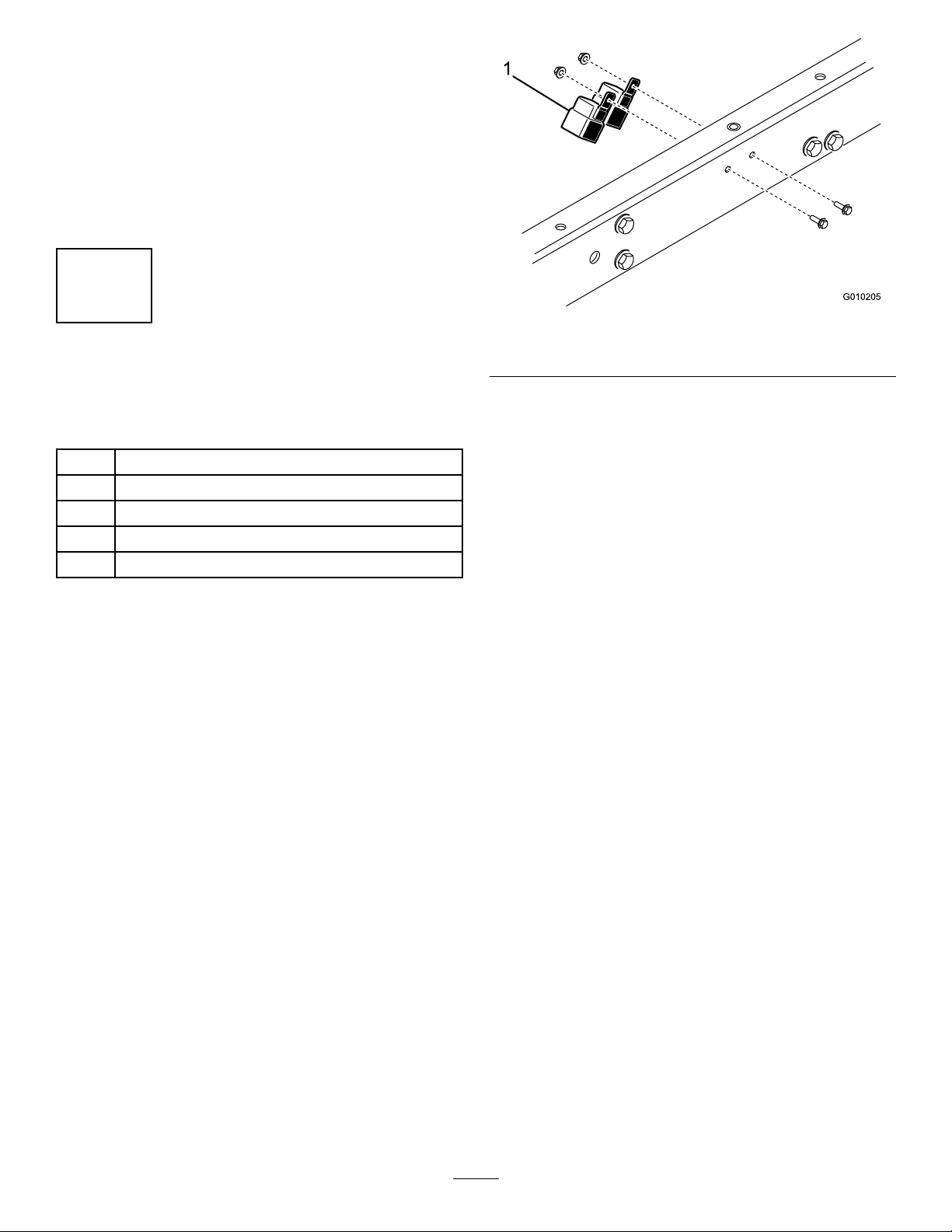

5MountRearLevelSwitch...................................9

6ReinstallHood................................................10

7MountLiftontoVehicleFrame........................10

8ConnectWires.................................................11

9ReconnectBattery...........................................11

10MountCircularBubbleLevel..........................11

11InstallDecals.................................................12

ProductOverview......................................................13

Controls.............................................................13

Operation...................................................................14

CheckOilLevel..................................................14

CheckTirePressure............................................14

EngagingSafetyLocks........................................14

OperatingtheLift...............................................15

OperatingTips...................................................17

Maintenance...............................................................19

CheckSafetyCircuits..........................................19

BatteryCare.......................................................19

Schematics.................................................................21

©2011—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN554202

Contactusatwww.Toro.com.

PrintedintheUSA.

AllRightsReserved