KAL-K

Page 4 KAL-K K03/0516

Sensor

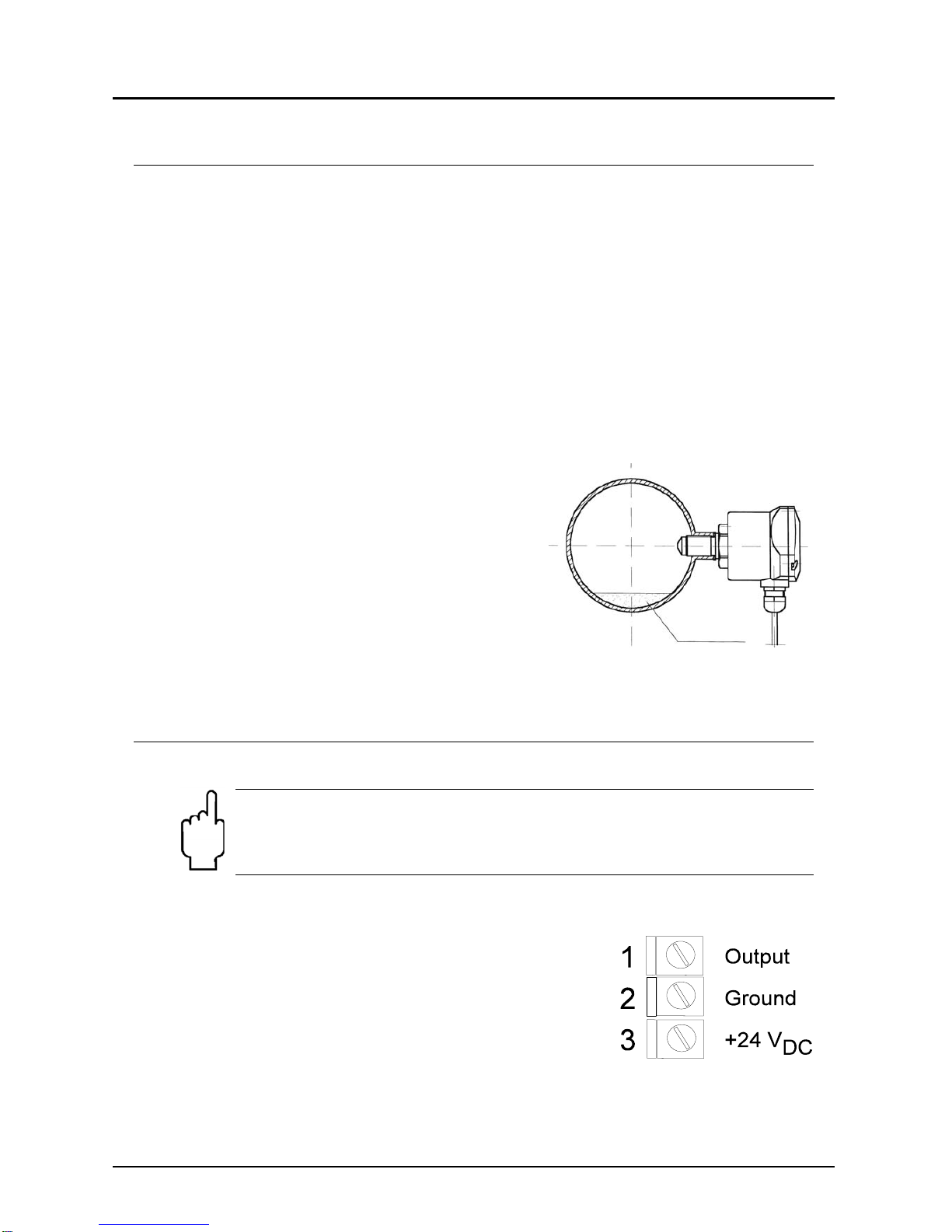

The model KAL-K consists of a sensor with integrated electronic.

The devices may only be used for liquids to which the probe material is resistant.

With proper installation and maintenance, the probes are not sensitive to soiling

and cause practically no pressure loss.

Materials

Sensor Stainless steel (1.4301, 1.4305, 1.4571)

Electronic housing Polyamide (glass fibre reinforced)

Setting ranges

in relation to nominal tube diameter

ND (mm) Meas. range (L/min)

water ND (mm) Meas. range (L/min.)

water

8 0,12 - 6,0 40 3,0 - 150

10 0,19 - 9,4 50 4,7 - 235

15 0,42 - 21,2 60 6,8 - 340

20 0,75 - 37,7 80 12,0 - 603

25 1,18 - 59,0 100 18,8 - 942

30 1,70 - 84,8 150 42,4 - 2120

Attention! The flow ranges specified in the table above have been

calculated for each pipe diameter based on the known velocity

range of the KAL-K. It must be noted that flow in pipes is non-

uniform across the pipe cross section, and approaches zero at the

pipe wall. This means that, in practice, the depth of installation of

the probe, the internal pipe diameter, and the flow profile of the

liquid in the pipe can interact to produce significant deviations from

the flow ranges in the above table.

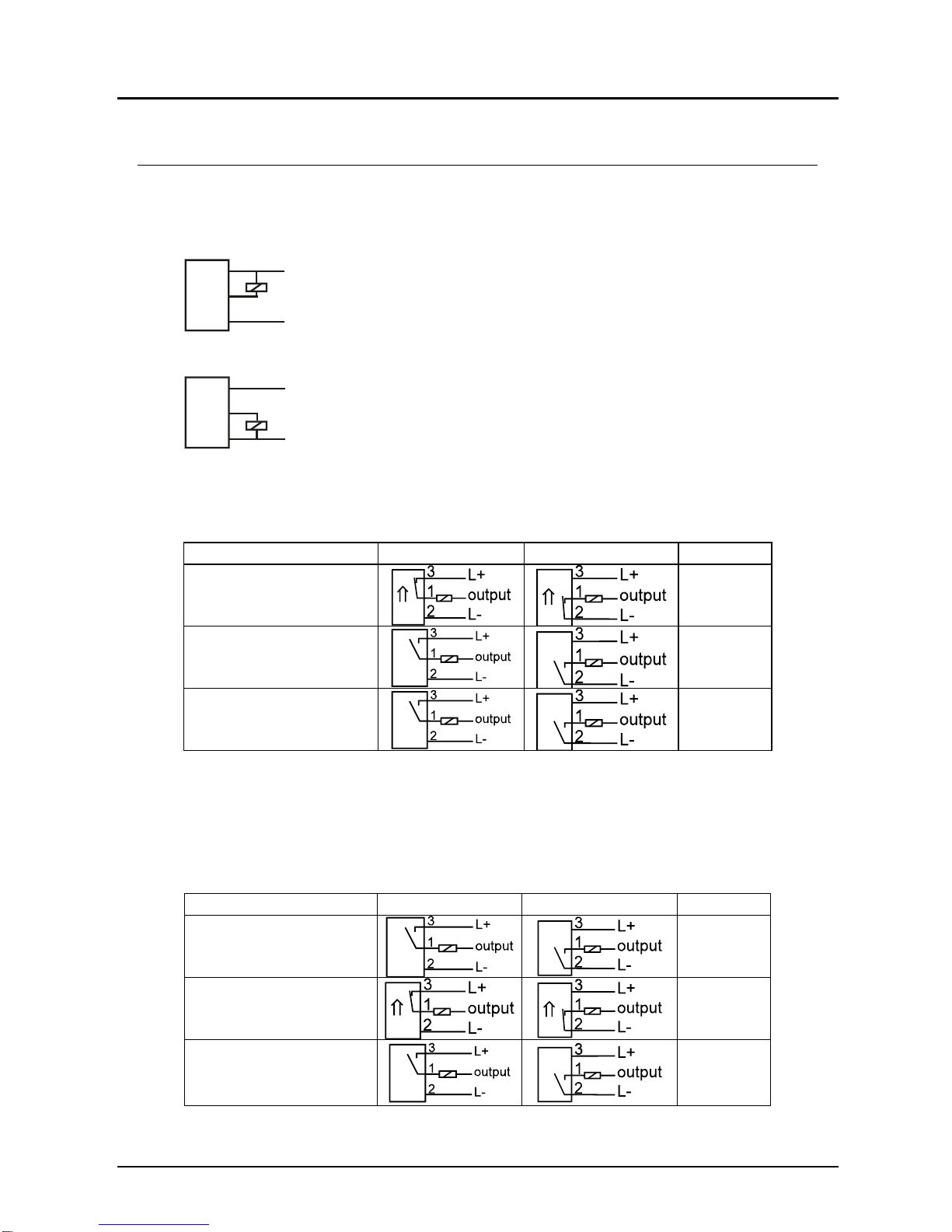

5. Operating Principle

The KAL-K Flow Monitor uses the proven thermal dispersion principle and

operates as follows. The probe is heated internally to a few degrees above the

temperature of the medium into which it extends. The flowing medium removes

this heat from the probe. The cooling rate is proportional to the flow rate. The

measured flow rate is compared to the set point value selected by user. If the set

point is reached, the electronic circuit activates a transistor switch and bi-coloured

alarm LED. The electronic circuit also controls an LED trend indicator which can

be used to indicate relative system flow. The microprocessor- controlled design

permits sample calibration and set-up. The compact probe design permits

monitoring of flow rate with minimal pressure loss.