TTL

DT0463 page 2

1 Contents

1Contents ................................................................................................................. 2

2Note ........................................................................................................................ 4

3Instrument Inspection ............................................................................................. 4

4Regulation Use ....................................................................................................... 4

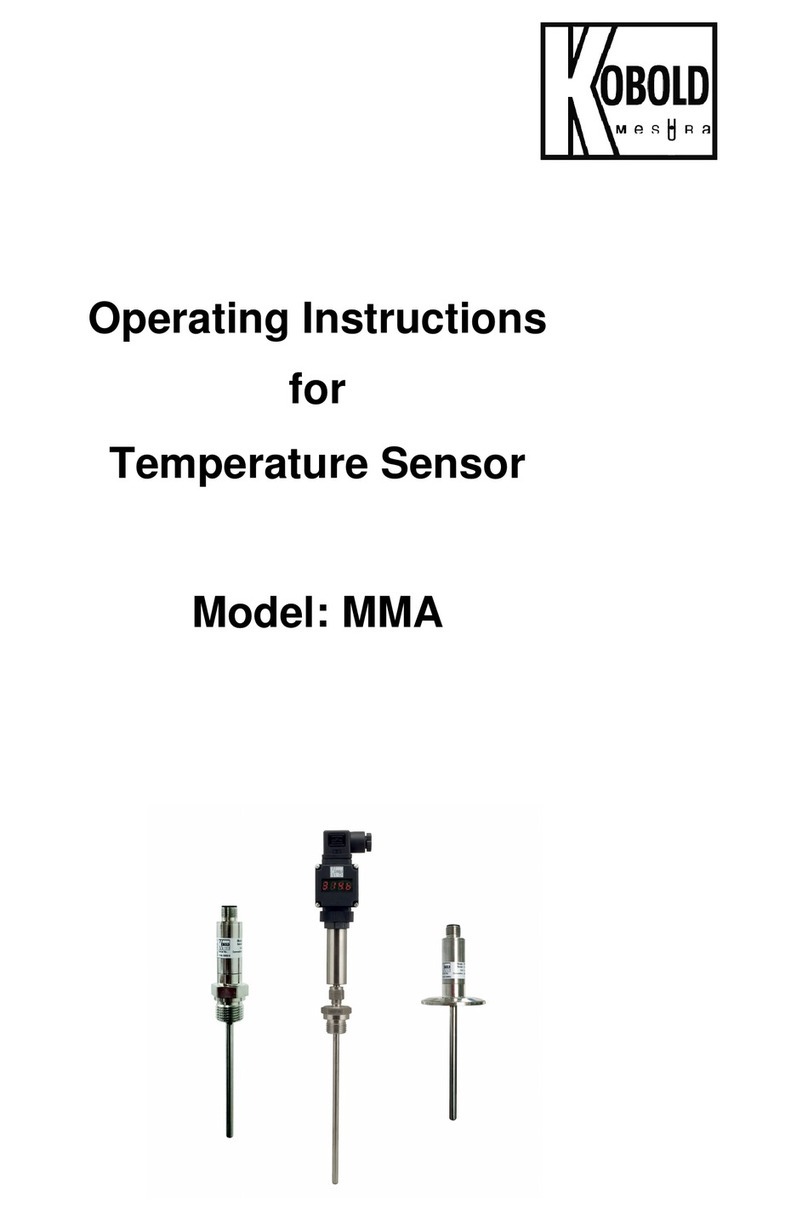

5Operating Principle ................................................................................................. 5

6Use in hazardous Areas ......................................................................................... 5

6.1Area of validity .................................................................................................. 5

6.2Guidelines ........................................................................................................ 5

6.3General ............................................................................................................ 6

6.4Protection against E.S.D. (Electrostatic Discharge) ......................................... 6

6.5Maintenance and repairs .................................................................................. 6

6.6Storage............................................................................................................. 6

7Description of the Factory Label ............................................................................. 7

8Installation in the classified area ............................................................................. 7

8.1Examples of installation in explosion-proof areas conform to the protection

type “intrinsically safe”: “Ex ia” ................................................................................... 7

9Technical Details .................................................................................................... 8

9.1Sensor and accuracy ....................................................................................... 8

9.2General details ................................................................................................. 9

9.3Materials ........................................................................................................... 9

9.4Process connection .......................................................................................... 9

9.5ATEX-approval ................................................................................................. 9

9.6Head transmitter ............................................................................................... 9

10Dimensions ........................................................................................................ 10

11Order details ...................................................................................................... 12

12EU-Certificates .................................................................................................. 17

13ATEX-Certificates .............................................................................................. 18

14Notes ................................................................................................................. 23

15Notes ................................................................................................................. 24