Thermo Technologies USDT 2004B User manual

USDT 2004

Installation and User’s Guide

Introduction

General Information 2

Installation

Collector Sensor 3

Control Box 5

Operation

Power Connection 6

Operating Display 6

Changing Factory Settings 8

Manual Operation Of Pump 9

Advance Operation 10

Frost and Overheating Protections 12

Energy Calculations 14

Troubleshooting 15

Thermo Technologies

9009 Mendenhall Place • Suite E

Columbia, Maryland 21045

Phone 410.997.0778 • Fax 410.997.0779

e-Mail i[email protected]

Revision 4.0, October 2007

2

Introduction

Note: The information supplied in this manual is for guidance only -no part of this may be used

for any agreement, whether express or implied, or to form any contract. Thermo Technologies

reserves the right to change specifications without prior notice.

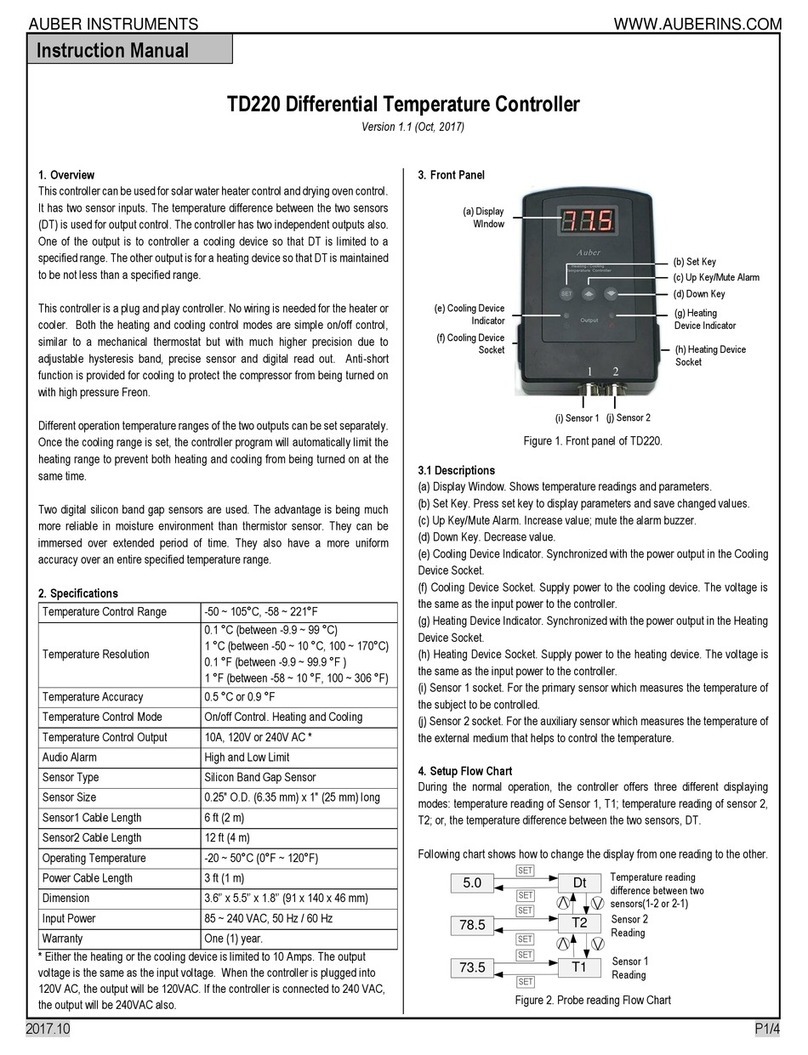

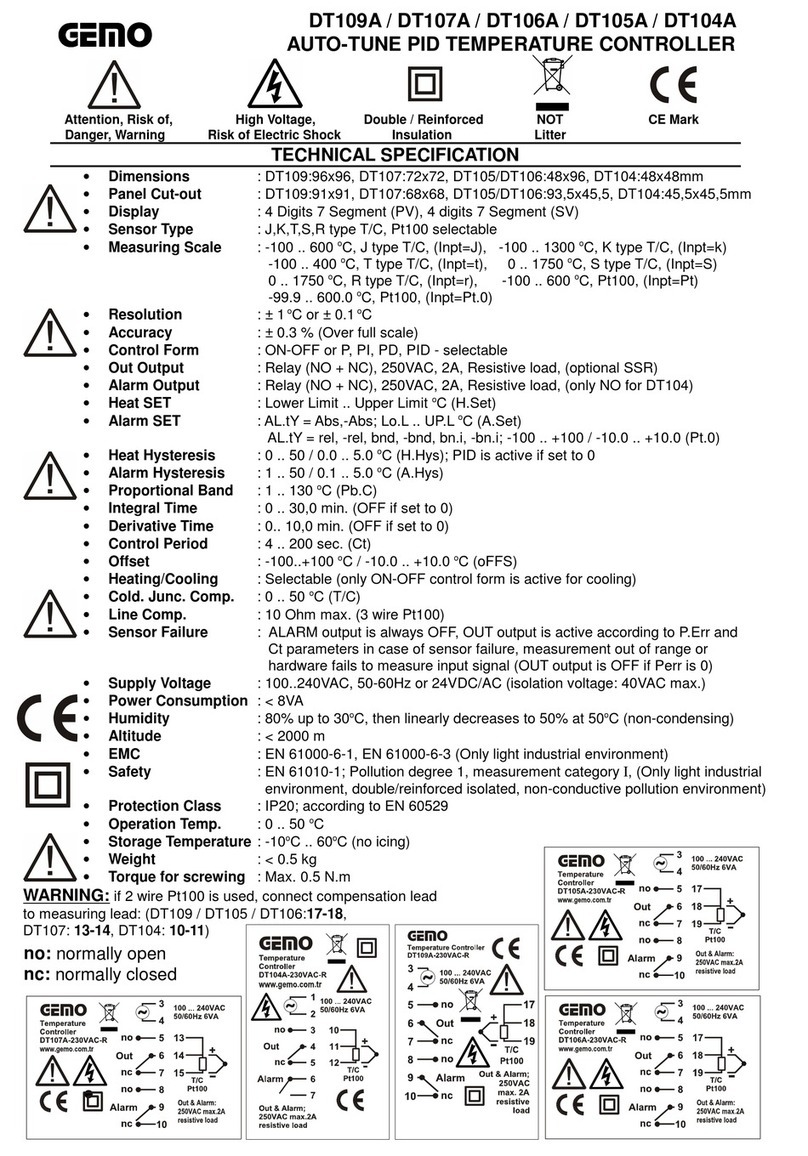

SDT 2004 is a powerful temperature differential control unit and may be used in a wide

range of applications. The user has the choice of *two modes:

Par Mode (access code 32) –This program is USDT 2004's basic program. It uses two sensors

to control a simple solar water heating system and factory settings may be altered.

Men Mode (access code 64) -This program, initiated by the user, customizes USDT 2004 for

applications involving a BTU Meter or where a third sensor (or reference value) is required.

*NOTE: USDT 2004 may be used for several advanced applications originating inMen Mode.

USDT 2004 has the following functions:

•2 inputs for temperature sensors

•Input for flow rate input or additional temperature sensor

•BTU meter capability for constant flow rate or with a puls flow meter

•Adjustable (-4o F to 39 o F) frost protection

•Adjustable (32 o F to 299 o F) overheating protection

•Adjustable (1o F to 99 o F) temperature difference ?T

•Manual pump operation

•Digital display of all parameters

•System status and diagnostic displays

Two -Sensor Operation

At its most basic function, USDT 2004 is a two-sensor

solar hot water controller. One sensor (S1 in diagram)

monitors the collector temperature whilst the other sensor

(S2) monitors the temperature at the bottom of the

storage tank. The solar loop circulation pump runs while

the collector temperature exceeds the tank temperature

by an adjustable temperature difference diff. To avoid

overheating, the circulation pump stops if the tank

temperature (T2) reaches the adjustable high limit (TMAX)

temperature. The pump A1 runs only when the

temperature at the collector sensor location S1 is higher

than the tank temperature at location S2 by at least diff

(?T). The pump stops if diff is less than the preset value

or, when the temperature at location S2 has reached the

TMAX :A1 (ON) only when S1 > (S2 + diff) & S2 < T max

The temperature hysteresis (a lagging in the set-point) may over-ride diff to avoid pump cycling.

U

S1

S2

A1

3

INSTALLATION

Note: This installation procedure is for guidance only, and the installer should verify its

suitability. Make sure that the solar system is physically installed, manually tested, and ready for

controlled operation.

he following safety precautions are strongly recommended:

1. Before attempting to install and operate the unit read this instruction manual carefully.

2. Only suitably qualified personnel should carry out installation and required maintenance.

3. It is recommended that the unit be connected to the power supply via an on/off switch or plug.

4. WARNING: When the unit is connected to the 115-volt power supply and the cover is

opened, high voltage circuits will be exposed. When installing the unit, all required

connections should be completed and the cover attached to the controller box before turning

the power on. Ensure that all connections are secure. If any maintenance work is required

isolate the unit from the power supply before removing the cover. Never leave the unit

unattended if the cover has been removed and the power supply is connected.

5. Do not exceed unit ratings of 3.15 amps (1/6 HP or 245 Watts pump).

6. It is advisable to route power cables away from sensor cables.

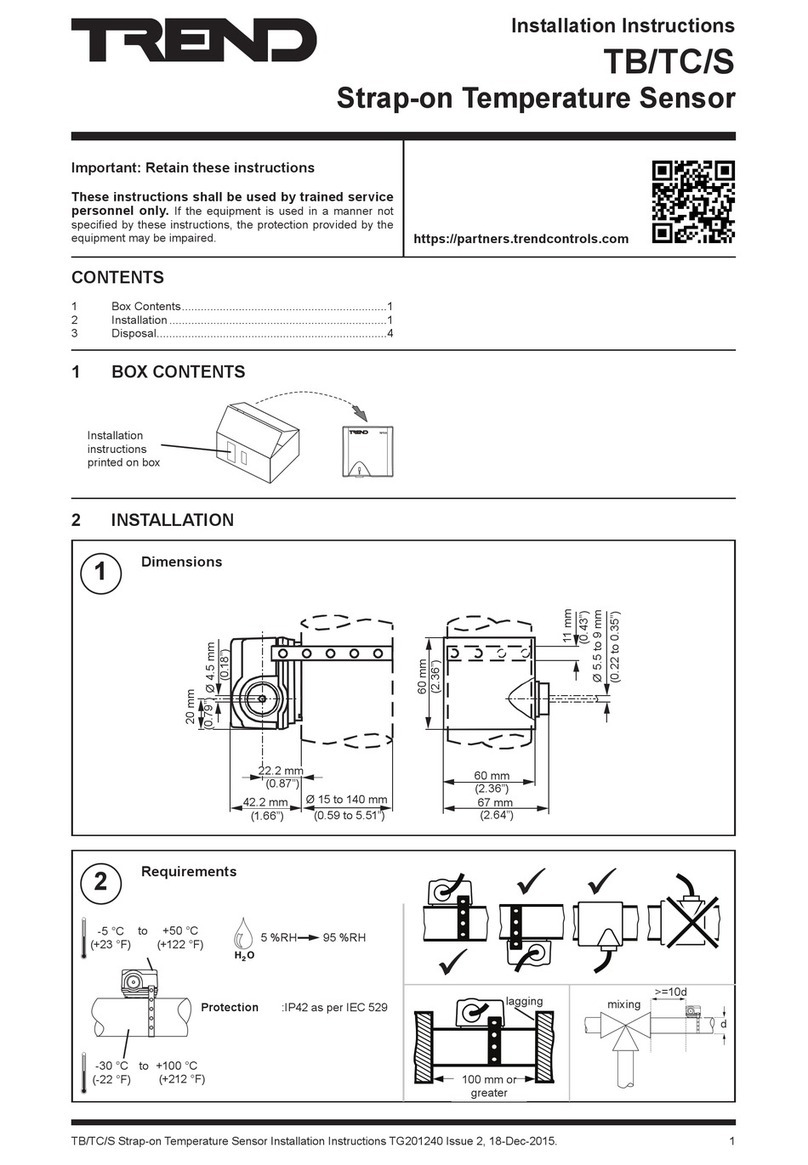

ensor installation: Temperature sensors may be installed in fluid lines by mounting in a

well or strapping directly to piping. For the system to function correctly, it is essential that

the sensors are located and installed properly. Sensors must be well insulated in order to

prevent influence by the ambient temperature.

When used outdoors, water must not enter the immersion sleeves. Exposure to moisture (e.g.

condensation) can diffuse through the cast resin and damage the sensor.

Corrosion-resistant immersion sleeve (sensor pockets) must be used when sensors are used in

open loops or swimming pools.

l Collector sensor (red cable with protective terminal box): Push into a thermowell, (sensor

pocket), which is soldered or riveted directly to the manifold (vacuum tubes). Alternately, strap

the sensor to the collector outlet pipe or the absorber (flat plate collectors) that projects from the

collector housing. Ideally, house the collector sensor (encased in a suitable sensor pocket) into a

T-piece on the collector return outlet. Protect the sensor cable from UV and moisture.

T

S

4

l Tank sensor (white cable): This sensor, required for the solar loop return, is installed in the

lower part of the storage tank. If there is no provision for this tank sensor, push the sensor

beneath the insulation –keeping it close to the inner tank wall at the desired tank location.

For external heat exchangers, the tank sensor should be installed with an immersion sleeve in the

return leg (cold side) of the heat exchanger. In tanks with integrated heat exchangers, the sensor

pocket should be fitted at the exchanger's return to the collector.

l Pool sensor installation: Place a heat conductive T-piece on the suction line directly at the

pool outlet and screw in the sensor with an immersion sleeve (check corrosion resistance of the

material used). Alternately, attach the sensor with clips or adhesive tape, using the appropriate

thermal insulation to guard against environmental influences.

l Sensor cable extension: Sensor cables (22/4 AWG telephone cable; only two wires of 4)

can be extended up to 150 ft. A connection between the sensor and extension can be established

as follows:

Cut the supplied heat-shrinkable tubing to desired length (about ½ ”). Slide tubing over one end of

wire to be sliced (after removing enough outer insulation to accept the tubing). Splice the wire

and slide tubing over the splice. Heat gently all around until tubing shrinks tight.

Slide larger tubing (about ¾ “) over the entire splice. Heat gently all around until tubing shrinks

tight. This connection can then be drawn gently into the pipe work. Only two of the wires are

required for the sensor cable; the other two wires are kept spare.

Caution:Do not overheat the tubing! Remove heat as soon as the tubing shrinks tight, as

material will continue to shrink. With a heat gun or flame source, use an even back and forth

motion all around tubing. Let tubing cool for maximum strength.

ontroller unit installation: For viewing comfort, the controller unit should be positioned at

eye level. For optimum longevity, avoid extremes of temperature in the placement of

electronic equipment. In addition, avoid heavy electrical loads, switches or contactors as these

may cause electrical and electromagnetic interference with the unit (when switched on or off).

C

5

Undo the screw at the top of the housing. The control electronics are mounted on the enclosure

cover. The controller enclosure can be screwed to the wall with cable entry grommets pointed

downwards. Use the supplied plastic bridges to secure power and sensor cables.

Base of the unit to be mounted at eye-level and wired as shown above

Caution: Controller wiring should only be done when the unit is not energized. It is possible to

damage the control unit if it is assembled under voltage. Miniaturized terminal blocks are used for

making wiring connections. The wire is held in place within the terminal with screw that provides

excellent contact without damage to the wire.

Sensor Cable Connection: Use up to an 18 or 22 AWG stranded wire to connect the sensor

cables to the unit. The S1 terminal should be connected to the collector sensor (higher

temperature); the S2 terminal is designated for the tank sensor (lower temperature). And the S3

terminal is reserved for the advanced usage of the unit such as a third temperature sensor or flow

meter input for BTU operation.

6

ower Connections: A small blade screwdriver may be used to fasten miniaturized

terminal block screws while the corresponding wire is inserted.

NOTE 1: Always disconnect the controller from the power supply before opening the

housing.

NOTE 2: The controller should be properly grounded. Flexible wires, 18/3 AWG

(gauge/conductor) simplify connection to the terminals. The power terminal block will

accommodate wire sizes up to 14 AWG. All connections should be secured and adequately

tightened, as loose power connections will over-heat, and may cause fire.

NOTE 3: It is important that the specified output loads (245 Watts) are not exceeded. Where

these loads expect to exceed, external relays must be used. It is good practice to install a switch

to disconnect the controller and pump from power. Always keep power cables away from sensor

cables and other low voltage signal cables.

NOTE 4: To protect against lightning damage, the system must be grounded according local

regulation. Sensor failures due to the weather or electrostatic are mostly due to poor grounding.

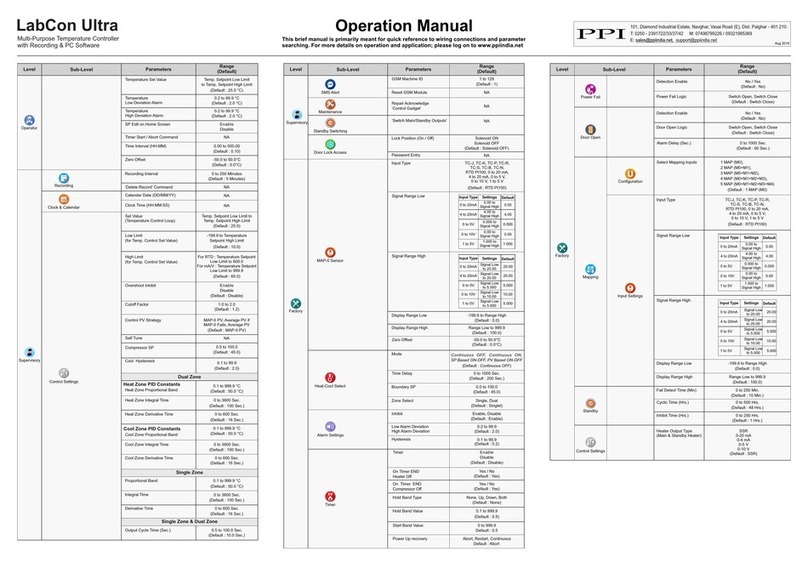

OPERATION OF

DIGITAL DISPLAY

our controller displays information one request at a time. The unit display window has

three lines to inform you about the system's status, unit of displayed parameter and

its value.

Upper Line Display Symbolic display of sensor location, reading unit, and operation domain

Center Line Display Sensor ID and its reading in normal mode (user interface window)

Lower Line Display Set-point indicator that illuminates only during programming mode

ðPush selection key once to move to the next selection; or increase the selected

parameter by one unit while display is blinking.

ïPush selection key once to move to the previous selection; or decrease the selected

parameter by one unit while display is blinking.

P

Y

Y

7

òPush selection key once to enter the advanced (Par or *Men) mode. Once in selected

mode, press one more time to select the parameter in that mode. Selected parameter

blinks allowing the user to modify it. You can modify the selected parameter while the

middle window blinks by pressing the ïor ðkey.

ñPush selection key once to accept selection (blinking stops showing the new set-point

steady) or go back to the previous selection.

*Men mode is for use with advanced applications.

Use selection keys ïð during normal system operation to display the desired parameter:

T1 xxx Collector temperature in oF

T2 xxx Tank temperature in oF

T3 xxx Reading of the third sensor; if the third sensor displays a fixed reference

temperature of 999 oF, the sensor designation can be wrong or the sensor is not

connected correctly (open circuit).

G xx Flow rate [gallon/h] –programmable by user

XX xxx Collector power in [kW] –amount of energy collector is producing

YY xxx Energy collected in [MWh]

ZZ xxx Energy collected in [kWh]

STAT Display of the system’s status. Any current problems outlined.

Example: The following windows display the temperatures of T1 (the collector), T2 (the

bottom of the tank) and T3 (3rd sensor see P.11)

At the upper text line, the icon for the text is always displayed. Program symbol is displayed

during the setting of parameters at the lower text line

Basic Mode (Par): Pressing the selection key ðseveral times allows you to navigate sensor

temperatures and energy output and also access (Par)mode. Push selection key òonce to enter

the program mode.

Advanced Operations: Pressing the selection key ðseveral times allows you to enter into the

advanced mode (Men). Push selection key òonce to enter the program mode.

8

CHANGING FACTORY SETTINGS:

Temperature differentials and manual operation of pump

Par Mode is USDT 2004's basic program; it uses two sensors to control a simple solar

water heating system. The unit is already factory set with ON/OFF pump temperatures.

However, these temperatures may be altered if required:

Par Using the navigation key ^_ allows you to select the desired parameter while you are in

the program mode. Press the selection key òonce to select the parameter in the window.

Selected parameter blinks allowing you to modify it. You can modify the selected parameter while

the middle window blinks by pressing the ïor ðkey. The unit accepts the new value by pressing

the ñkey once. Please make sure that you are in Par mode.

RUV 3.5 –Displays the software revision number corresponding to this manual.

PR O –Inapplicable

PROGRAMMING THE TEMPERATURE RANGE

USDT 2004 is factory set at approx T2 > 161 oFPUMP OFF, T2 < 150 oFPUMP ON. Once Par

mode has been accessed, using Code 32 as illustrated above, the user may program a different

temperature range. There are two temperatures that should be entered:

9

Tank Overheating Protection

In Par Mode, user can customize the temperature range by using max?and max=.Use the

navigation key ^_ in Par to locate max temperatures and push selection key òonce to make

changes:

max?1Pump stops above tank temperature (T2)

max=1Pump runs again below this set point (T2)

Temperature Differential Adjustment

diff=1Pump runs when temperature difference between collector T1 (collector) and T2

(tank) exceeds this value. Factory setting is 15.1 oF. Consult your collector

manufacturer for the recommended value.

diff?1Pump stops when temperature difference between collector T1 (collector) and T2

(tank) reaches this value. Factory setting is 7.0 oF. Consult your collector

manufacturer for the recommended value.

Manual Operation of Pump

The pump can be manually turned on or off once Par mode has been accessed using Code 32:

AUTO Use the navigation key ^_ in Par to locate the pump window O AUTO.Push

selection key òonce to enter pump operation (ON or OFF). When the manual mode

has been selected, an icon (a small icon symbolizing a right hand image) appears

under the text line.

Automatic mode

Manual ON

Manual OFF

10

ADVANCED OPERATIONS

or 3rd sensor designation

Men Mode customizes USDT 2004 for applications in conjunction with a BTU meter, a third

sensor or reference value. If BTU capability is not required, this program may also, for

example, measure the flow rate or the temperature of the storage tank (T3, top of the tank).

Men Use the navigation key ^_ to navigate to the Men Window. Use Code 64 to access and

program Men mode.

Navigation of advanced features of the unit and selection of parameters is the same as before by

using ïòñðkeys:

Advancing –Press the Advance key ïð briefly to advance to the next selection or to

increase/decrease the set point of the selected parameter. Hold it down for fast change.

Acceptance –Press Set-Up key òonce to select the parameter. Press ñkey to accept the

selection or the set point.

ENGL –Pre-Set to English. Spanish available in INTER.

CODES –64 for Men Mode.

SENSOR : USDT 2004 accepts two different sensor types or a reference value. Press the

Advance key ïð briefly until SENSOR appears in centerline and press the key ò. Ensure the

reference value readsKTY sensor, all factory supplied sensors are KTY type:

SDT 2004 is extremely powerful. All factory settings can be changed to meet the

unique requirements of other applications. All advanced operations have their origin in

Men Mode where USDT 2004’s parameters may be altered depending on the

application.

U

11

The factory setting will be retrieved by pressing and holding òkey during powering of the unit. A

“WELOAD” displays for three seconds while factory settings are restored.

Mode Operation

SENSOR Selects sensor type

SGUARD Protects system from overheating and frost

START Starts pump at pre-set insolation (solar radiation intensity)

ATAfter-running time. Factory-set at 0.

ALARM Enables/Disables protection functions

BTU Energy calculation and setting

ensor Designation –USDT 2004 accepts two different sensor types or a reference

value . User can program a constant reference temperature instead of a sensor output.

The factory-preset sensor is the thermistor (KTY 10) type. The KTY 10 tank sensor,

white wire, should be used in a conditioned environment and will not be permanently damaged up

to 360 oF.

Selection:

S1 Sensor 1 (collector outlet) selection

S2 Sensor 2 (collector inlet) selection

S3 Sensor 3 (tank) selection

Designation:

PT PT 1000 sensor (1000 Oat 0 oC, not available in US market)

KTY Thermistor sensor (2000 Oat 25 oC)

GBS Radiant sensor (not available in US market)

(- Fixed value, the unit uses this value instead of measured temperature

S3(-S1 Transfer of values (not used in program 0 operation)

DIG Digital input (not used in program 0 operation)

OFF The sensor reading is not displayed

VSG Flow rate reading

Sensor wires can receive electromagnetic pulses, which can result in a wrong temperature

reading. The USDT 2004 reads sensor values every 50 ms. It can bundle several readings and

process their average.

AV 1 Sensor 1 average

AV 2 Sensor 2 average

AV 3 Sensor 3 average

The numbers of samples can be programmed from 4 to 20.

S

12

rost and overheating protections -Pump operation can be manipulated by the user in

both collector stagnation and frost conditions. This set-up is possible in System Guard,

SGUARD, Men domain.

Overheating protection (CET) –The Circulation pump may not be powerful enough to circulate

the heat transfer fluid in the solar loop with air pockets. User can program the pump to stop at a

desired maximum collector temperature, shown by ?symbol, to protect the pump. USDT 2004

will take over the normal operation after the temperature decreases to an acceptable working

temperature, shown as =. This feature (ON) can be disabled by user to (OFF). Factory setting

is 260 oF to stop the pump. The pump starts again at 230 oF. Customer in field can change these

settings.

Frost Protection –Frost protection in the sun-belt region is provided by circulating water in the

solar loop when freezing conditions exist. Regardless of the temperature difference ?T, the

circulation pump runs when the collector temperature is below a programmable minimum

temperature, shown by =symbol. The pump stops as soon as the temperature in the solar loop

reaches a safe region programmed by the ?symbol. This feature is disabled at the factory and

displayed as (OFF).

min=Pump runs below this temperature (factory setting 35 F)

min?Pump stops above this temperature (factory setting 39 F)

tart functions -The Circulation pump can be programmed to start on a low insolation

level. The Start function feature is useful when heat transferred to the collector sensor is

not fast enough for an early start; especially when the collectors are flat mounted.

The enabled start function runs the pump at a given solar radiation or programmed temperature

difference. The feature is disabled at the factory.

START Start function screen

ON Enable start function

OFF Disable start function

If this feature is selected, following parameters must be adjusted for proper operation:

GBS Pyranometer port designation (radiation monitoring sensor port)

1 Sensor 1

2Sensor 2

3 Sensor 3

-- Manual input in next step

INS Radiation threshold in W/m2

CIRC Pump runtime in seconds

INT Maximum interval time in second

FLU Number of flushes

The following example activates the circulation pump at 200 W/m2and runs it for 15 seconds. If

rT condition is met within the time period, the pump stays on.

INS 20 CIRC 15

F

S

13

After-running time AT –During the start phase, the pump may repeatedly switch on and off for a

long time, especially systems with long solar loop. The after-run time AT can be changed from 0

(factory setting) to 9 minutes.

larm functions -User can enable the alarm function of the USDT 2004 in the ALARM

screen. Status of sensors and circulation pump can be viewed if alarm function is active.

A ON Alarm function enable

A OFF Alarm function disable

The status of the system can be monitored in the Stat Mode only if the corresponding feature is

active. The following example shows a system condition with a circulation problem:

CET OFF Collector excess temp. cut-off active (no error occurred)

CET ON No overheating

1 SHORT Short circuit in sensor 1 wiring

2 SHORT Short circuit in sensor 2 wiring

1 OPEN Disconnection in sensor 1 wiring

2 OPEN Disconnection in sensor 2 wiring

OK System operates normal

NO CIRC rT is more than 108 oF in last 30 minutes

OK CIRC Pump is running

CLEAR Clears NO CIRC display after correction

A

14

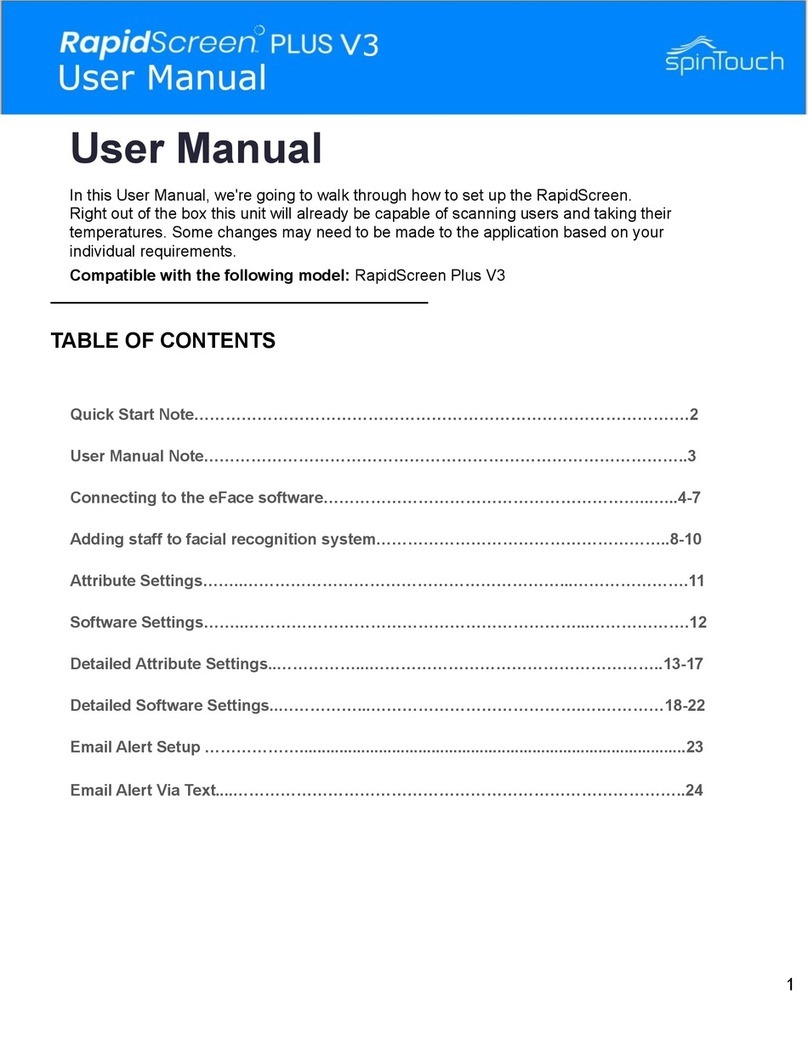

nergy calculation -Energy gain is calculated by obtaining the temperature increase of

the heat transfer fluid as it crosses the solar collector. The amount of fluid flow through

the collector is registered by an in-line flow meter. USDT 2004 computes the energy production

as a function of the temperature differential and fluid volume. In addition, the system anti-freeze

(Glycol) percentage should be entered as it affects the thermal conductivity and heat transfer

rate.

BTU Energy calculation mode

S IN Sensor port selection for inlet temperature (1, 2, 3, --)

S OUT outlet temperature (1, 2, 3, --)

F SEN Sensor port selection for flow rate (1, 2, 3, --)

Energy calculation will be initiated only after temperature sensor ports are designated. Flow rate

can be either a constant number to be entered by user, or from a flow meter input. To activate the

energy calculation without using the flow meter's impulse input, a dash (-) must be selected for F

SEN channel followed by the constant flow rate in gph (gallon per hour) unit:

GAL Constant flow rate in gph instead of flow meter reading in (--) sensor mode

Select 3 for F SEN when a flow meter is used:

LPP Flow meter rate impulse number in liter per pulse, if flow meter is used

GLYCOL Anti-freeze percentage

DIF (- Sensor calibration

The output of USDT 2004 unit is kW for system power and kWh or MWh for collected energy. The

energy calculation dependents on flow meter accuracy, the temperature sensors class, and their

locations. The flow meter is a mechanical device and its accuracy fluctuates over time. Therefore,

the user should calibrate the flow meter and incorporate temperature sensor tolerance.

The supplied Thermistor sensor has an accuracy of ±2 oF. DIF represents the temperature

difference between two sensors. User can increase the accuracy of reading by adjusting the DIF

parameter. To calibrate the system, insert both S IN and S OUT in the same temperature (such

as ice-water glass), DIF should show “DIF 0” for exact temperature reading. If it is not zero,

accept the difference for better accuracy. This difference will be used as a correction value for

energy calculation. The energy calculation becomes more accurate at temperature range that this

reading adjustment is made.

BTU CL Sets the BTU meter's counter to zero

CLEAR BTU meter's counter is zero

E

15

Troubleshooting

In general, if there is a malfunction all of the settings in the menus Par and Men and the terminal

should first be checked first.

Malfunction, but "realistic" temperature values:

•Check program number.

•Check the switch-on and switch-off thresholds and the set differential temperatures. Have

the thermostat and differential thresholds already been reached?

•Were the settings in the submenus (Men) changed?

•Can the pump (output) be switched on and off in manual mode? If a forced pump “ON”

and “OFF” lead to the appropriate reaction at the output, the unit is certainly in order.

•Are all of the sensors connected with the right terminals? Heat up the sensor using a

cigarette lighter and watch the display.

•Did you change the reference temperature 250 (three sensor operation) to KTY?

Incorrect display of temperature(s):

•Displayed values such as -999 if a sensor short-circuits

•or 999 if there is an interruption do not necessarily mean a material or terminal error.

•Are the right sensor types (KTY or PT1000) selected in the menu Men under SENSOR?

The factory settings set all inputs to KTY.

The sensor can also be checked without a measuring instrument by connecting the presumed

defective sensor to a terminal that works and checking the display. The resistance measured by

an ohmmeter should have the following value depending on the temperature:

T

0

10

20

25

30

40

50

60

70

80

90

100°C

R(KTY)

1630

1772

1922

2000

2080

2245

2417

2597

2785

2980

3182

3392 Ω

The settings of the parameters and menu functions ex works can be restored any time by

pressing the down arrow (enter) while powering the controller. The sign that appears for three

seconds on the display is RESTOR for load factory settings.

If the system is not in operation while connected to the power supply, the 3.15A quick-blowing

fuse that protects the control system and the output should be checked and exchanged if

necessary.

As the programs are constantly being improved, there may be a difference in the sensor, pumps,

and program descriptions. Only the enclosed manual (identical serial number) applies for the

equipment supplied. The program version for the manual must correspond to the equipment

version.

If the control system is found to be malfunctioning despite the checks described above, please

contact your retailer or Thermo Technologies directly. The cause of the error can only be

determined if the settings of the unit is known. The schematic diagram of the system in question

is a great help to isolate the potential problem.

This manual suits for next models

1

Table of contents

Other Thermo Technologies Temperature Controllers manuals

Popular Temperature Controllers manuals by other brands

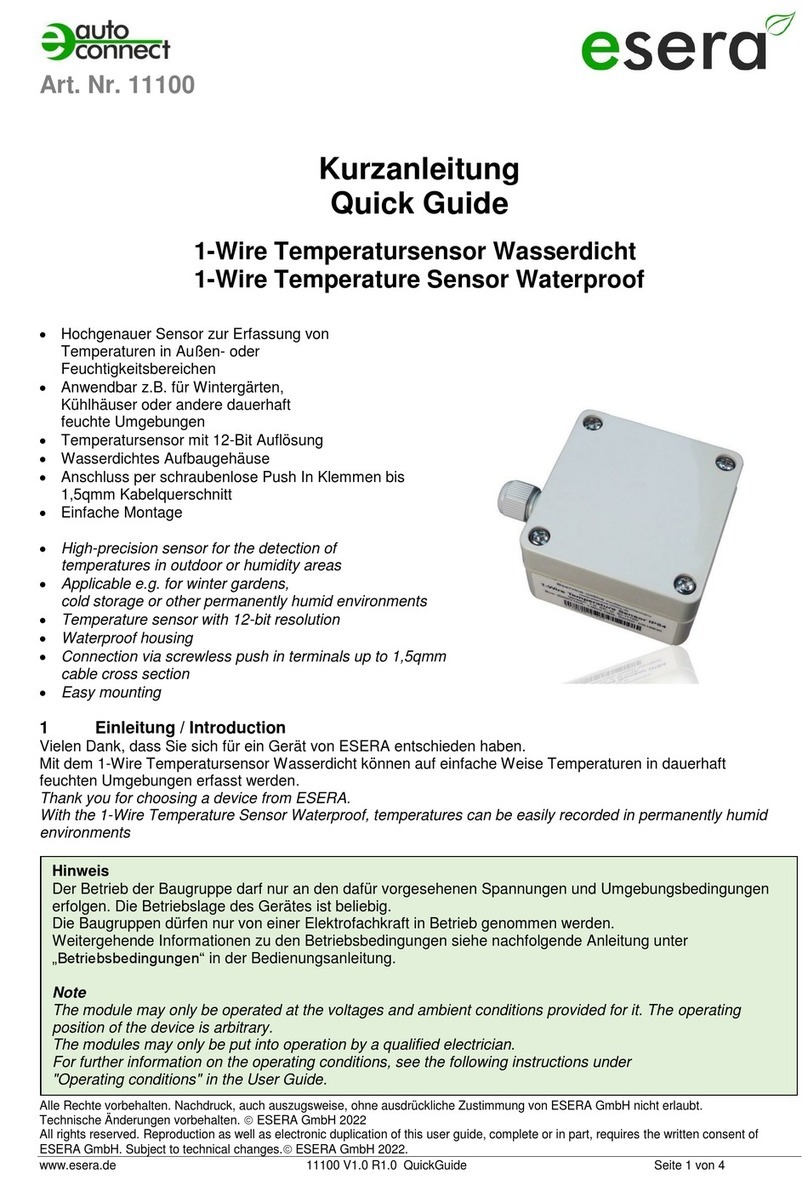

esera

esera 11100 quick guide

Apogee Instruments

Apogee Instruments ST-100 owner's manual

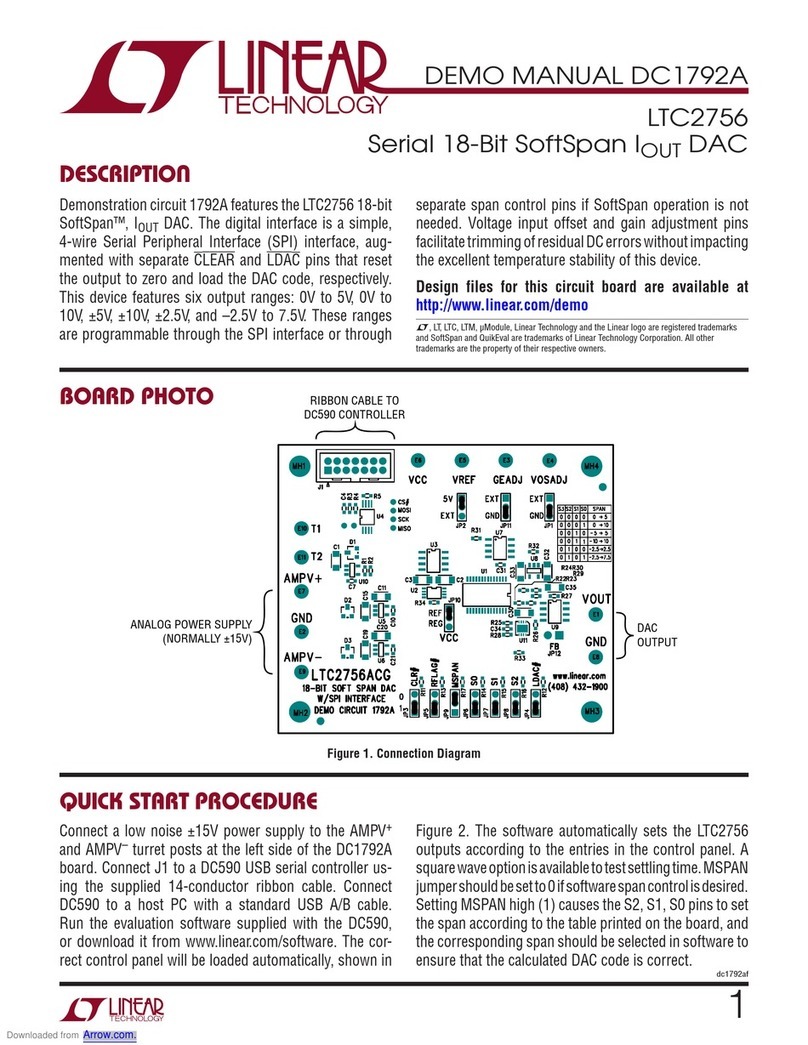

Linear Technology

Linear Technology DC1792A manual

Novus

Novus N1050 instruction manual

Omega

Omega RH32 Series Basic instructions

S+S Regeltechnik

S+S Regeltechnik HYGRASGARD RFF Operating Instructions, Mounting & Installation