Pre-Operation Note

Thank youfor your purchase of the LGSG13HC Professional Stump Grinder. This stumpgrinder has been

designed and manufactured to our highest quality demands for durability and performance.

The LGSG13HC Professional Stump Grinder is warranted to be free from manufacturer's defects in material

and workmanship for a period of one (1) year from the date of purchase. This warranty will be void if the machine

has not been operated and maintained in the manner prescribed in this Operator's Manual. Any machine malfunctions,

and/or warrantyclaims that arisefrom themisinterpretation or themisunderstanding of theinstructions and

cautions discussed in this booklet will not be eligible for warranty protection.

In order for thestump grinder to perform at its optimum capabilities, the operator must readthis manual thoroughly

before using this unit. This Operator's Manual contains important product operation procedures, safety precautions,

maintenance and troubleshooting tips as well as other advisories. Please keep this manual both this manual and the engine

manufacturer's manual in the manual storage pack, located on the handle, at all times nearby when operating the machine

as a reference should any questions arise. If the machine is sold or transferred to another user, pleaseensure that this

manual accompanies it. Ifthe machine is soldor transferred to anotheruser, please ensure that this manualaccompanies it.

The LGSG13HC stump grinder is designed for reducing tree stumps outdoors down to a manageable size. The machine

should not beused for any other purpose than that stated above.The inappropriate use of any machine can cause serious

damage and/or bodily harm to the environment and operator. It is imperative that the operator of this equipment be

responsible for the operational environment of the stump grinder.Please be preparedand well-informed for all specific

requirements and workhazards that mayand/or do existat the jobsite.

Powered by a 13 hp HONDAengine, the LGSG13HC isa powerful unit driving tough 355mm cutter wheel with eight

replaceable carbide teeth to make stump removal fast andeasy.The LGSG13HC has many features which are designed to

improve your working experience. The steelcutter wheel guard and heavy-duty chip curtains increase safety by shielding

the operator from the cutter wheel and flying debris. A six-position adjustable handle with operator presence system

maximizes comfort and ease of use. Heavy-duty inner and outer belt guards protect the operator and increase belt longevity.

To extend engine life,an angled frame keeps the engine level during the grinding process. A power band belt with idler

bearing provides efficientgrinding. Increased stability and ease of start-up is provided by a square foot rest for pull-start

models.

In order for you to enjoy the most out of your new stump grinder, always keep safety as a priority. Inspect your

jobsite for any debris such as rocks, wiring, string or any other items that can become hazardous during work. Identify

and mark all fixed objects to be avoided during work such as sprinkler heads, water valves, buried cables, or clothes

line anchors etc.The jobsite environment, soil conditions, job specifications and operator experience will all be factors

that must be considered to select the proper tool for the job. Failure to maintain the stump grinder in a proper manner

will lead to decreasedproductivity of the tooland hazards to theoperator and bystanders. Do not use the machine if it has

been modified orimproperly maintained.

All jobsites are different.Please ensure that when using the Stump Grinder, all local bylaws and codes are

followed. All operators and mechanics of this machine should be trained in generalmachine use andsafety.

Every care andeffort has been made toascertain the accuracyand completeness ofprocedures described inthis

document to ensure your enjoyment and satisfaction.

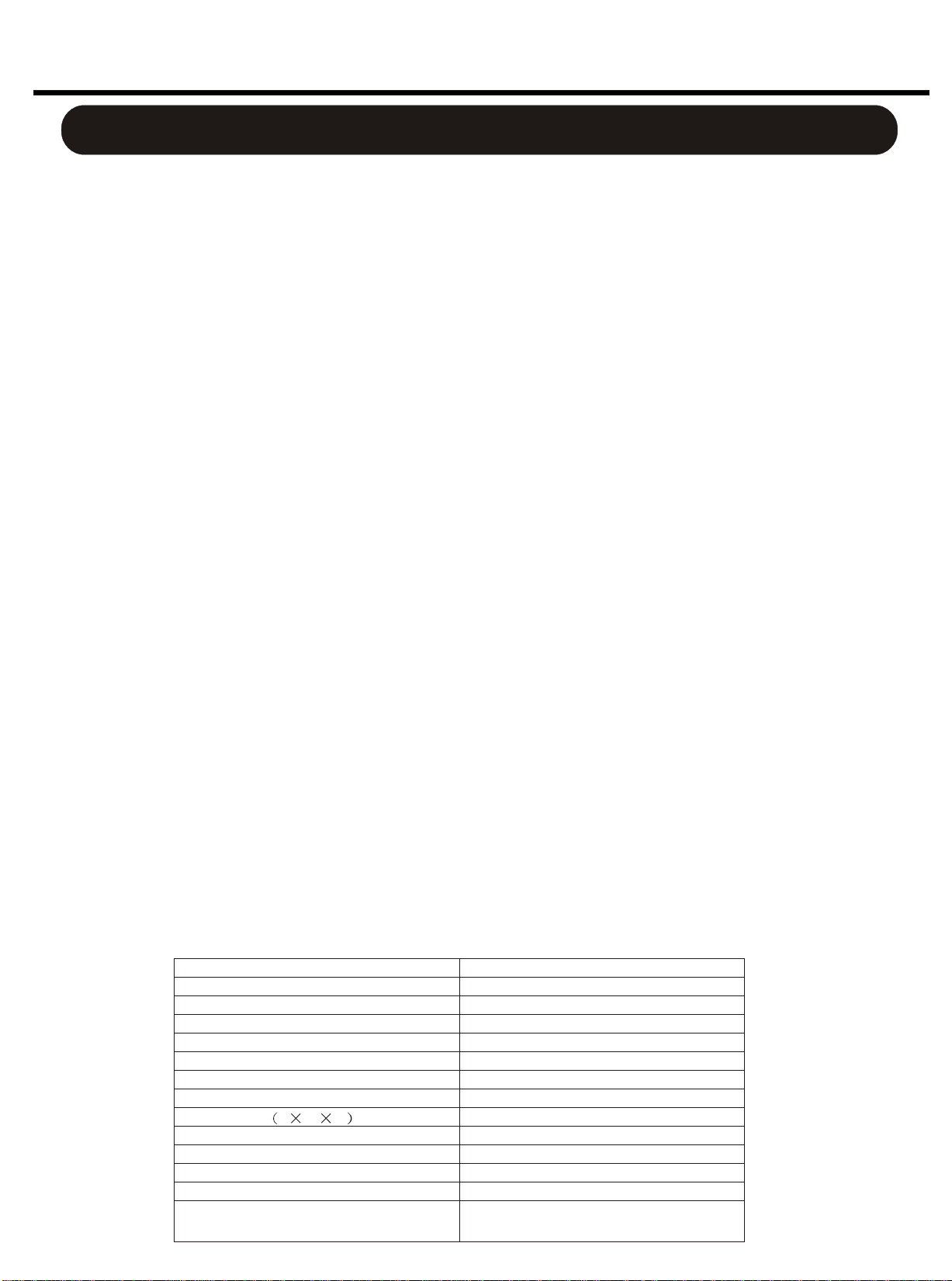

Model

Engine options

Cutter depth below ground

Cutter height above ground

Number of teeth on cutter wheel

Cutter wheel diameter with teeth

Fuel tank capacity

Tire size

Dimension L W H

Total weight

LGSG13HC

Honda GX390-13HP

229mm

534mm

8

355mm

6.1L

5.3/4.50-6 4PR

2131 mm×800 mm×897mm

137kgs

Product Specification

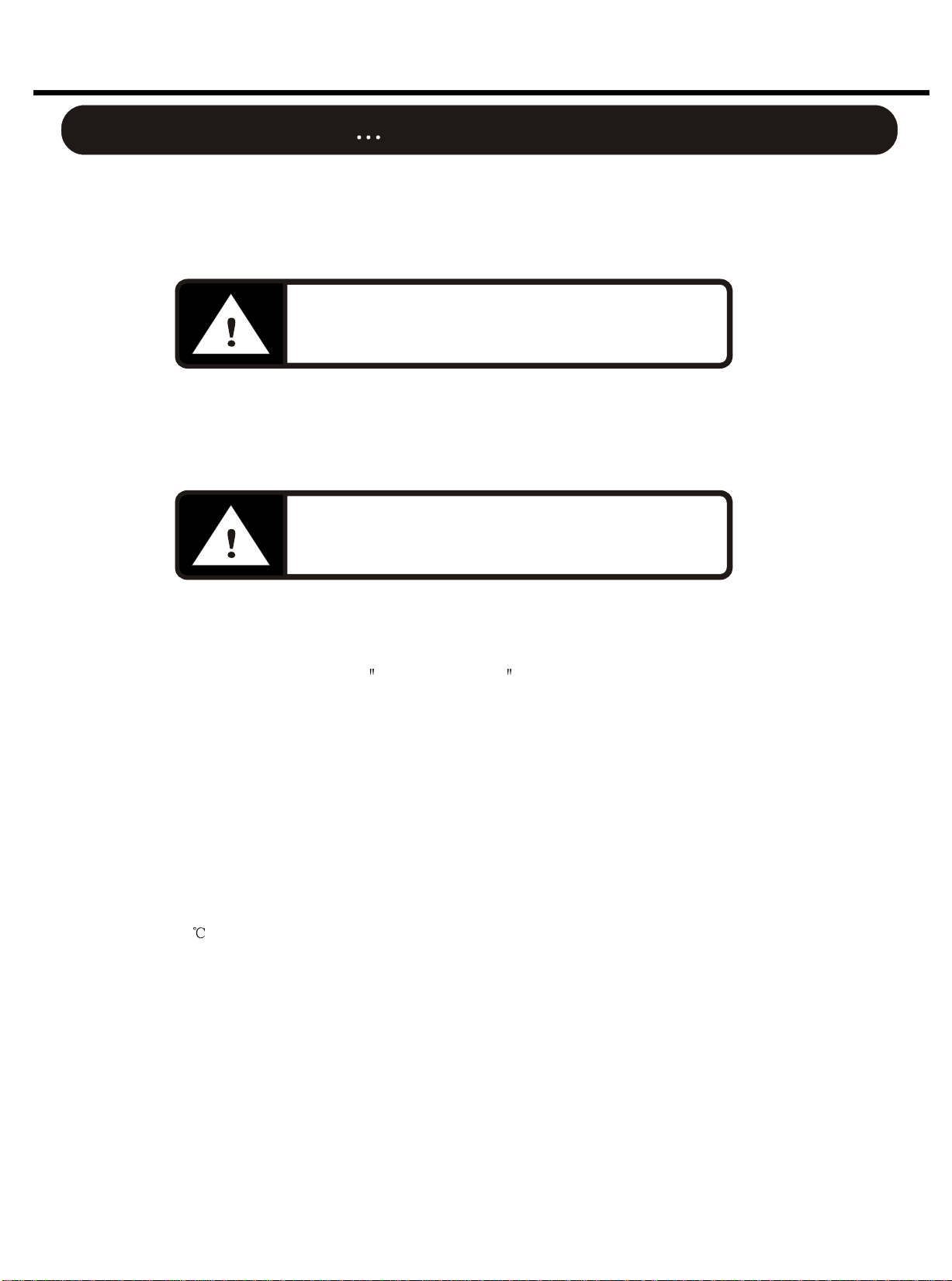

1

on handlebar grip

= 7.8m/s in accordance with 2002/44/EC K=1.5m/s

.

22

Guaranteed noise power level Lwa

Lpa at operator's position

'

Vibration acceleration value:

Von handlebar grip

a

hw = 8.6m/s

in accordance with 2002/44/EC K=1.5m/s

a

hw

22

106dB(A)

90.9dB(A) Kpa=2.5dB(A)

Noise level Lpa 83.82dB(A) Kpa=2.5dB(A)