2-3. Mounting

Securely mount this power unit on the mounting plate with reference to the outside

drawing in Fig. l. Form mounting, apply M3 small screws and consider the thickness of the

mounting plate to have a distance within 3mm to the main machine.

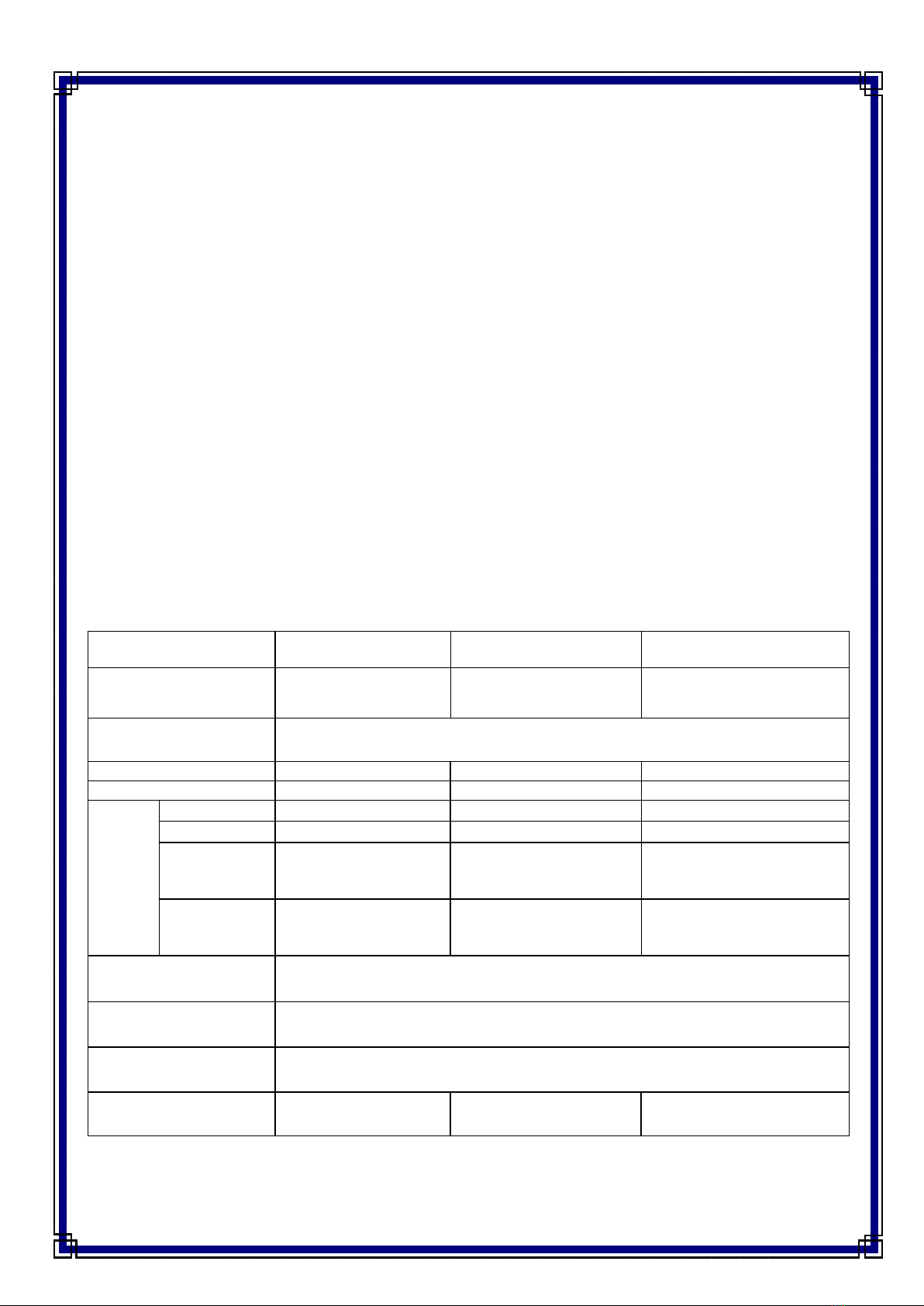

3. Wiring connection

3-1.Wiring connection with the mass flow controller (MFC) /

mass flow meter (MFM)

Connect the MFC or MFM to the 9P connector of this power unit with private purpose

cables corresponding thereto. When connecting the connector push-in it so that it mates

with the concavo-convex of the socket and pin units of the connector, and then tighten the

fixing thread on the cable side so as to prevent falling. See the attached connector shape

diagram and the standard schematics of model 3440 and 3660 mass flow controllers in the

attached Fig.1-4.

3-2 Wiring connection with the external appliances

Connect the external appliances to the 15P connector of this power unit with cables

applicable thereto. When connecting the connector, push-in it so that it mates with the

concavo-convex of the socket and pin units of the connector, and then tighten the fixing

thread on the cable side so as to prevent falling. See the connector shape diagram and the

standard schematics of model 3440 and 3660.mass how controllers in the attached Fig.1-4.