12/’18 KG

* For other details about specifications and precautions, see the catalog.

*For inquiries about the product, contact the Koganei overseas group at the

number below.

OVERSEAS DEPARTMENT

3-11-28, Midori-cho, Koganei City, Tokyo 184-8533, Japan

Tel: 042-383-7271 Fax: 042-383-7276

4. Avoid piping that is rigid, such as steel piping, if vibrations are transmitted.

Use flexible tubes so that the product is not subject to the vibrations.

●Usable medium

1. Use clean air (filtered to below 5 μm) for the medium. Contact the nearest

Koganei sales office or overseas department if you are considering using

something other than clean air.

2. Cannot use air that contains moisture and fluid.

3. If air that contains moisture and/or fluids is used, or if it is possible that

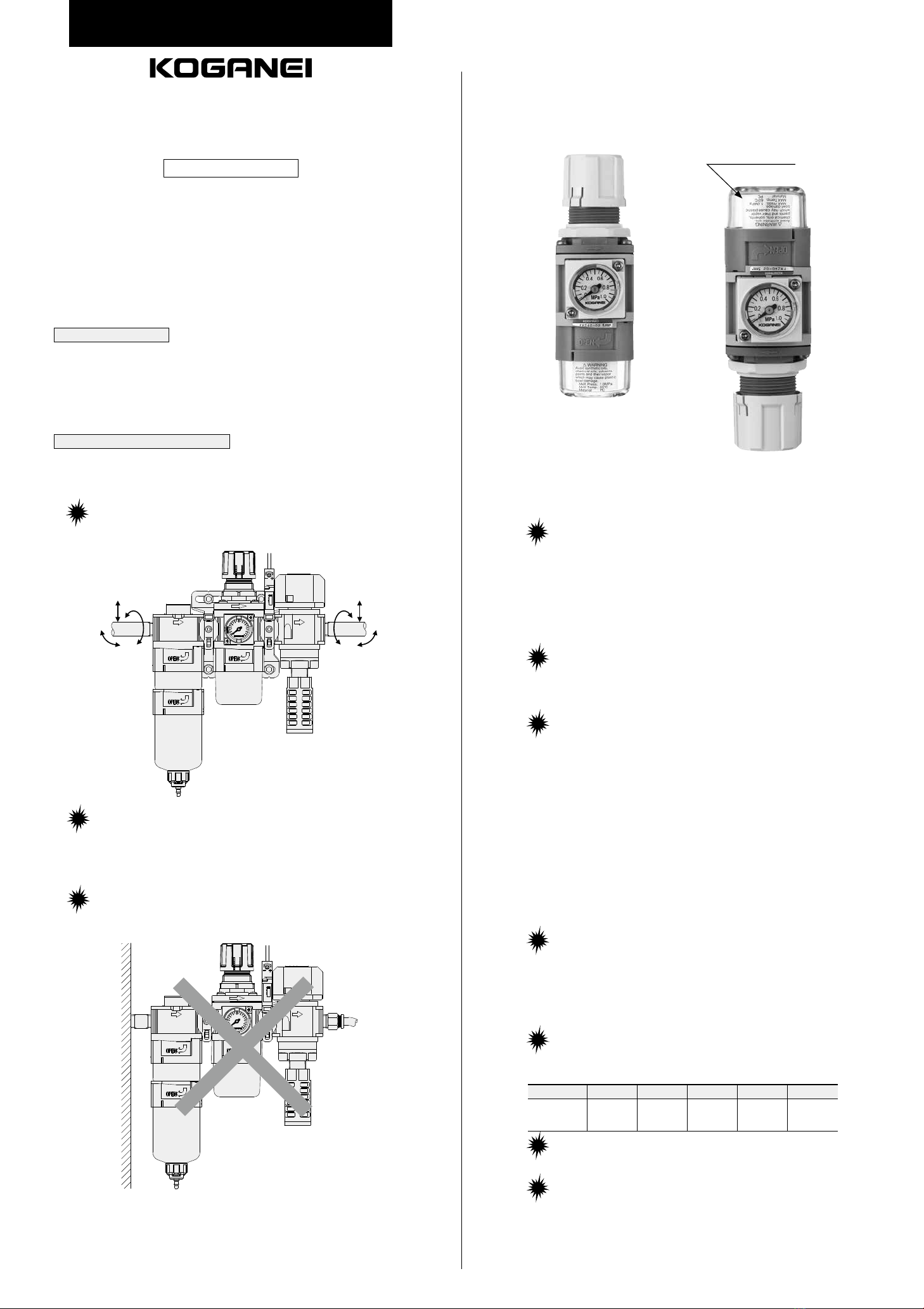

they may be mixed in with the air being used, we recommend using the

iB-Cyclone to reliably remove moisture and fluids.

4. Do not use the product if the medium being used is prone to extreme pul-

sating or surging.

●Operating environment

1. Do not use the product in locations that are subject to direct sunlight

(ultraviolet rays); locations with high humidity and temperature, dust, salt,

or iron powder.

2. Cover the unit when using it in locations where it might be subject to

excessive dust, dripping water, dripping oil, etc.

3. Do not use the product in environments subject to external vibration or

impact.

Medium and operating environment

Using air that contains too much moisture and/or fluids will cause the

product's functions to stop after a short period and will reduce the

product performance and service life.

If you use an iB-Cyclone, install an FRZ series filter regulator (without

water and fluids removal functions) on the secondary side.

Medium prone to extreme pulsating or surges will cause the product's

functions to stop after a short period and will reduce the product

performance and service life.

External vibrations or shocks may result in damage to component

parts.

Note

Note

Note

Note

Note

Note

Note

Note

●Medium and operating environment

1. The temperature of the medium and the ambient environment must be

within the range in the specifications.

2. Use a device, such as a freeze-type air dryer or after cooler, to lower the

dew-point temperature of the medium to below the ambient temperature

so condensation or frost does not occur in the secondary pipes.

3. Do not use medium in the product or use the product in an environment

that includes corrosive components such as organic solvents, phosphate

ester type hydraulic oil, sulfur dioxide, chlorine gas, freon gas, ozone,

acids, alkaline, etc.

4. The bowl and the front cover of the pressure gauge of the filter regulator

are polycarbonate. This product cannot be used in environments with the

gases and fluids in item 2, nor threadlocking adhesive, leak detection

fluid, hot water or where it may be exposed to them. This product also

cannot be used in direct ultra-violet light. See the catalog for details.

Using the product in an environment that is outside the specified

temperature or with medium that is outside the specified temperature

will cause the product's functions to stop after a short period and will

reduce the product performance and service life.

If condensation or frost forms in the product, it may get into the

secondary side.

Using the product in an environment or with medium that is specified

in the above item 3 will cause the product's functions to stop after a

short period and will reduce the product performance and service life.

Operation and maintenance inspections

●Method of use

Read the Handling Instructions and Precautions for each product for instruc-

tions on correct usage .

●Maintenance (maintenance inspection)

1. Performance and functions may decrease as the pneumatic equipment

ages. Always conduct daily inspections of the pneumatic equipment, and

confirm that all requisite system functions are satisfied, to prevent acci-

dents from happening.

2. Read the Handling Instructions and Precautions for instructions on main-

tenance and replacing maintenance parts .

3. The product must be disassembled and reassembled to use the seal kit.

The product is no longer under warranty if it is disassembled and

reassembled.

●Preventing contamination by foreign matter

1. Remove all foreign matter, such as metal chips, cutting oil, or dirt, from

inside pipes with compressed air blow (flushing) and thorough washing

before fitting the pipes.

2. Do not allow foreign matter, such as metal chips, or sealing tape from the

piping threads, to get into the pipes when installing the pipes and fittings.

Foreign matter entering the piping may damage the product or reduce

its performance and service life.

Note

Note

Note If liquid sealant gets on the polycarbonate parts, it may damage them.

4. If you are using liquid sealant, do not get it on the polycarbonate parts

(the bowl of the filter regulator and the front cover of the pressure gauge).

3. Wrap the sealing tape in the direction as shown in the diagram below

leaving 1.5 to 2 threads uncovered. When using liquid sealant, apply a

suitable amount and in the same way leave 1.5 to 2 threads uncovered.

If the sealing tape or sealant gets on the lip of pipes or

fittings, bits of it may get into the pipes and cause air leaks.

Leave 2 threads open Leave 2 threads open

Direction of

wrapping

Sealing tape

Liquid

sealant

aPM

.

.

.

4

.

1

2

3

0

0

0

0

SUP

0.80.2

0.4 0.6

0

MPa

1.0

MPa

iB-Cyclone

*See the back of the catalog.