KOHTECT BT-77

Current consumption 220, 50 Hz AC, not more than 5A.Currentconsumption220,50HzAC,notmorethan5A.

The limits of complementary error of the instrument at voltage changing fromThelimitsofcomplementaryerroroftheinstrumentatvoltagechangingfrom

3.6oltsto2.8olts.

Probabilityofno-failureoperation,notlessthan0.92per2000hrs.

Theaverageinstrumentlife,notlessthan10years.

Failuretime,1000hours.Theaveragefailuretimeissetforstan-dardconditions

foroperation.

Dimensions,notmorethan60х110х30(mm).

Weight,notmorethan210gram.

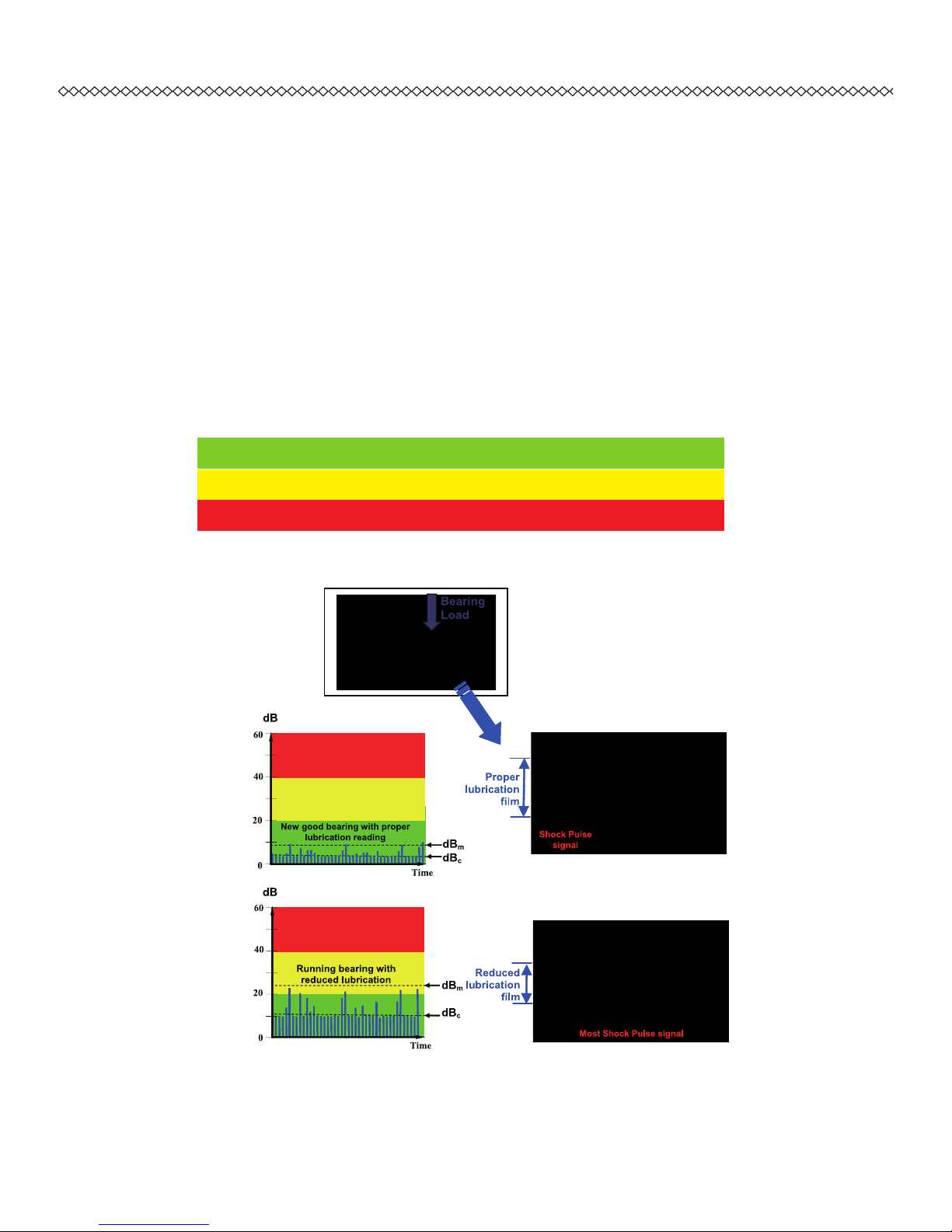

1.2 OverviewonRollingBearingConditionMonitoring

Ideally,rollingbearingelementsareseparatedbyaprotectivelubricantlm,which

impedes their collision. However, manufacturing defects, damages, which appear

duringoperation,dirtinthebearing,insufficientorincorrectlubrication–allthese

factorscausethecollisionofthebearingelementsand,asaresult,acoustic

oscillationsofawidespectrumaregeneratedinthebearingbody.

Aspeciallydesignedtransducer(patent№18652)isusedtolteroutthepartofthis

spectrumthatcarriesinformationonthebearingfaultsdetection.Thetransducerlters

thoseacousticoscillationswhicharegeneratedbythebearingdefects,andconverts

themintoelectronicsignalproportionaltothemagnitudeofshockpulsesignal,thatis

ampliedand measured bytheBT-77electronic unitintherelative units ofdecibels

(dB).

Arealnewbearingisjustfromthebeginningofitsuse,asourceofinducedvibration,

theamplitudeoftheshockpulseofwhichisdBi.

ThedBi,initialvaluedependsonthelargenumberoffactors;however,inpracticeitis

possibletolimitthemtodiameterD(mm)oftheneckanditsrotatingspeed�(rpm).The

•

•

•

•

•

•

•

2