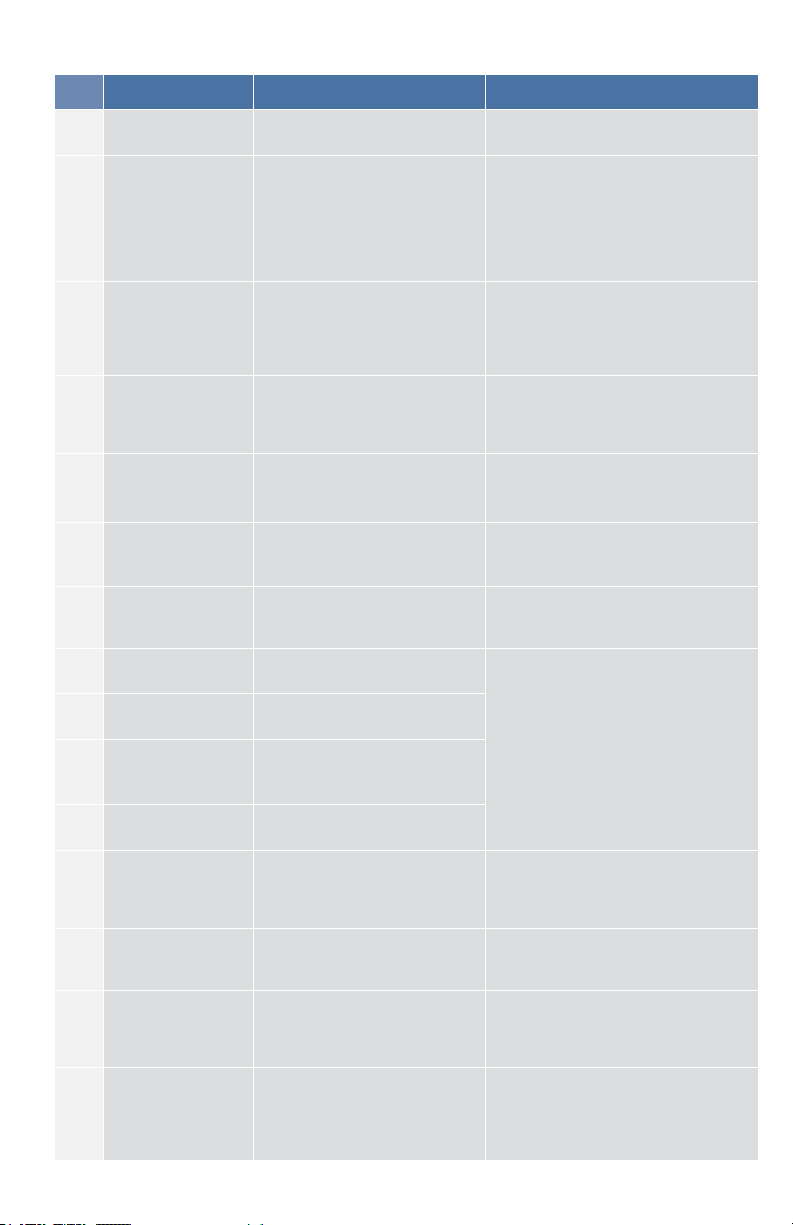

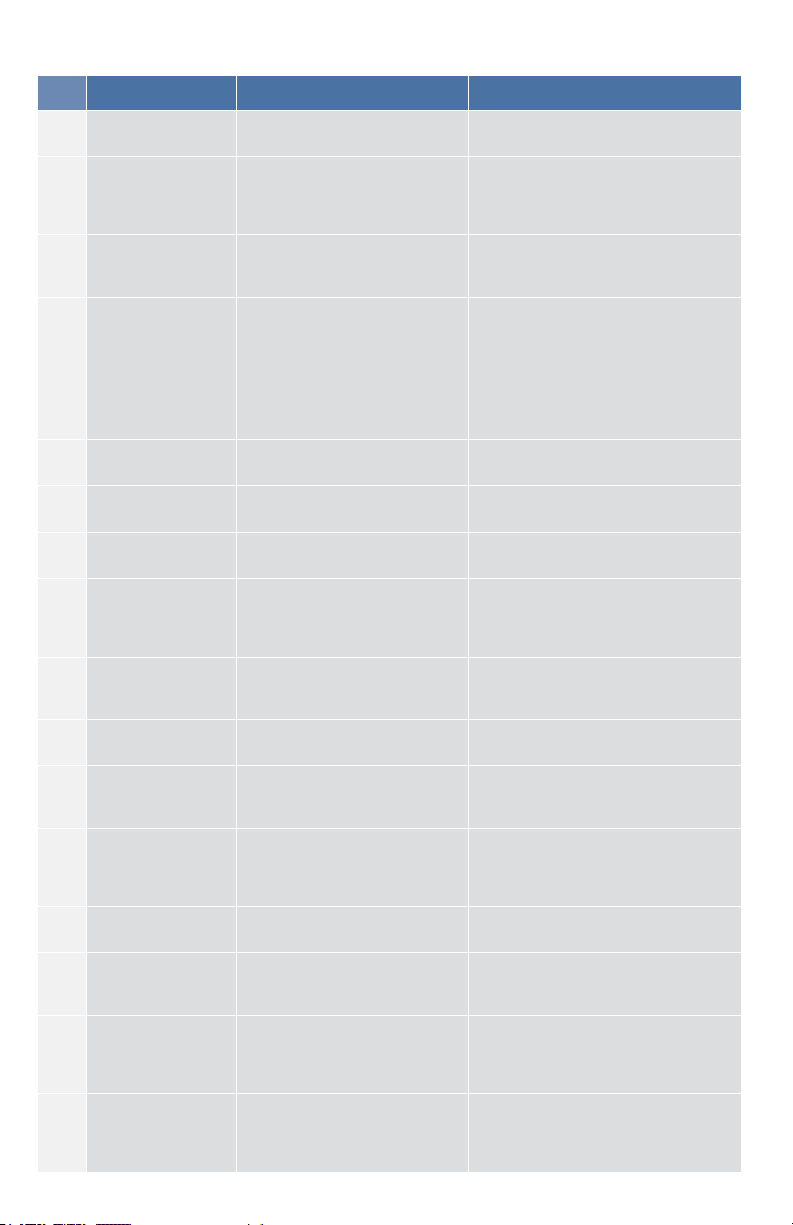

AKD PDMM Fault Card | F139– F154

Fault Message/Warning Cause Remedy

F139

Target Position

over short due to

invalid motion task

activation.

The drive cannot decelerate

from its current speed to

reach the end point of the

second motion task without

moving past it. Increase the

deceleration rate in the move

or trigger the move earlier

Change Motion task prole and

clear fault with DRV.CLRFAULTS

or change the value of FAULT139.

ACTION = 1 to ignore this condition.

n140

VBUS.HALFVOLT

has changed. Save

the parameters and

reboot the drive.

The user has changed the

numerical value of VBUS.

HALFVOLT. This change

only takes effect after a DRV.

NVSAVE command and after a

reboot of the AKD.

Save the parameters in the non

volatile memory using the DRV.

NVSAVE command and turn off/

on the 24[V] power supply in order

to reboot the drive or restore the

original setting of VBUS.HALFVOLT.

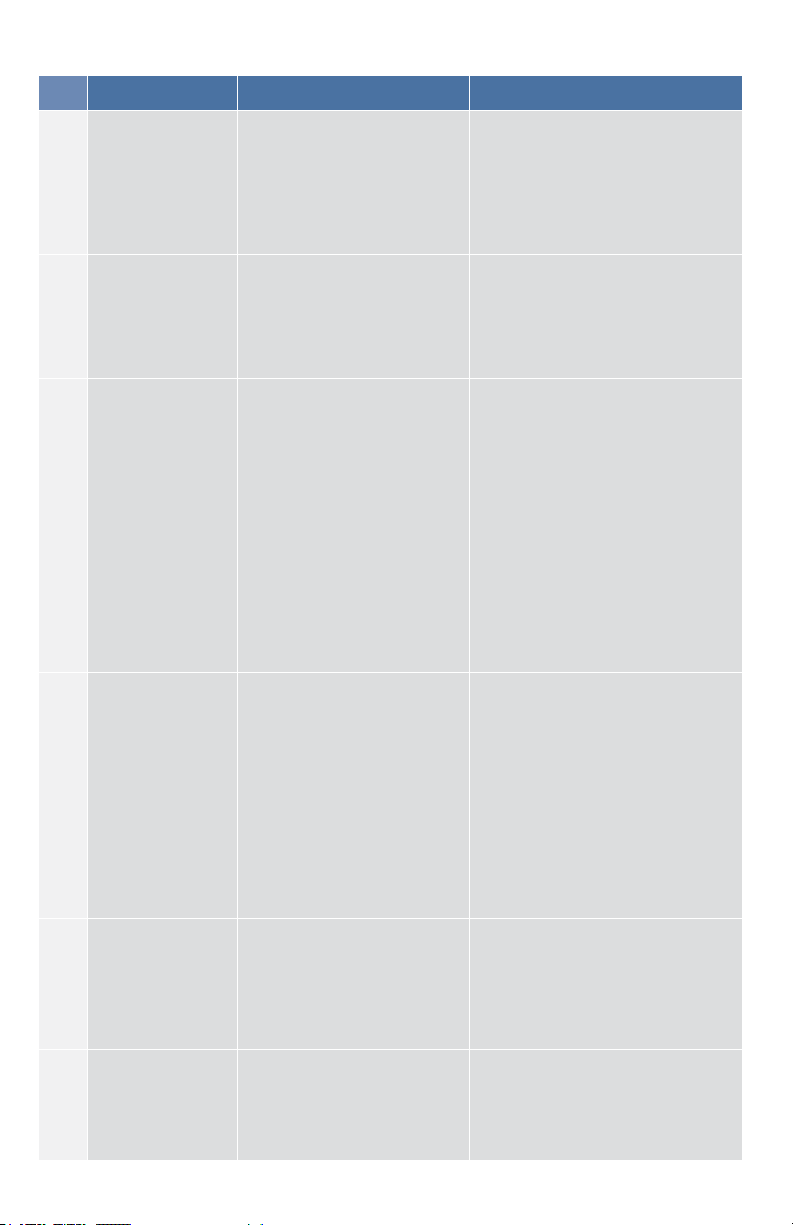

n151

Not enough

distance to move;

motion exception.

For trapezoidal and customer

table motion tasks: The target

velocity specied in the motion

task cannot be reached via

using the selected acceleration

and deceleration since the

distance to travel is not

sufcient.

For a 1:1 prole: The selected

acceleration and deceleration

will be extended since there

is too much distance to travel

and the motion task would

exceed its maximum allowed

velocity.

Activation of any new motion or

using of DRV.CLRFAULTS will clear

the warning. Check motion task

settings and parameters to make

sure that the values entered will

produce a valid motion task.

n152

Not enough

distance to move;

following motion

exception.

A new motion task activated,

when one motion task is

already active and the target

position specied in the motion

task parameters cannot be

reached with specied target

velocity, acceleration and

deceleration parameters.

The motion task will directly

decelerate to into the target

position or ramps down to

velocity 0 and start another

move to reach target position

of the next motion task.

Activation of any new motion or

using of DRV.CLRFAULTS will clear

the warning. Check motion task

settings and parameters to make

sure that the values entered will

produce a valid motion task.

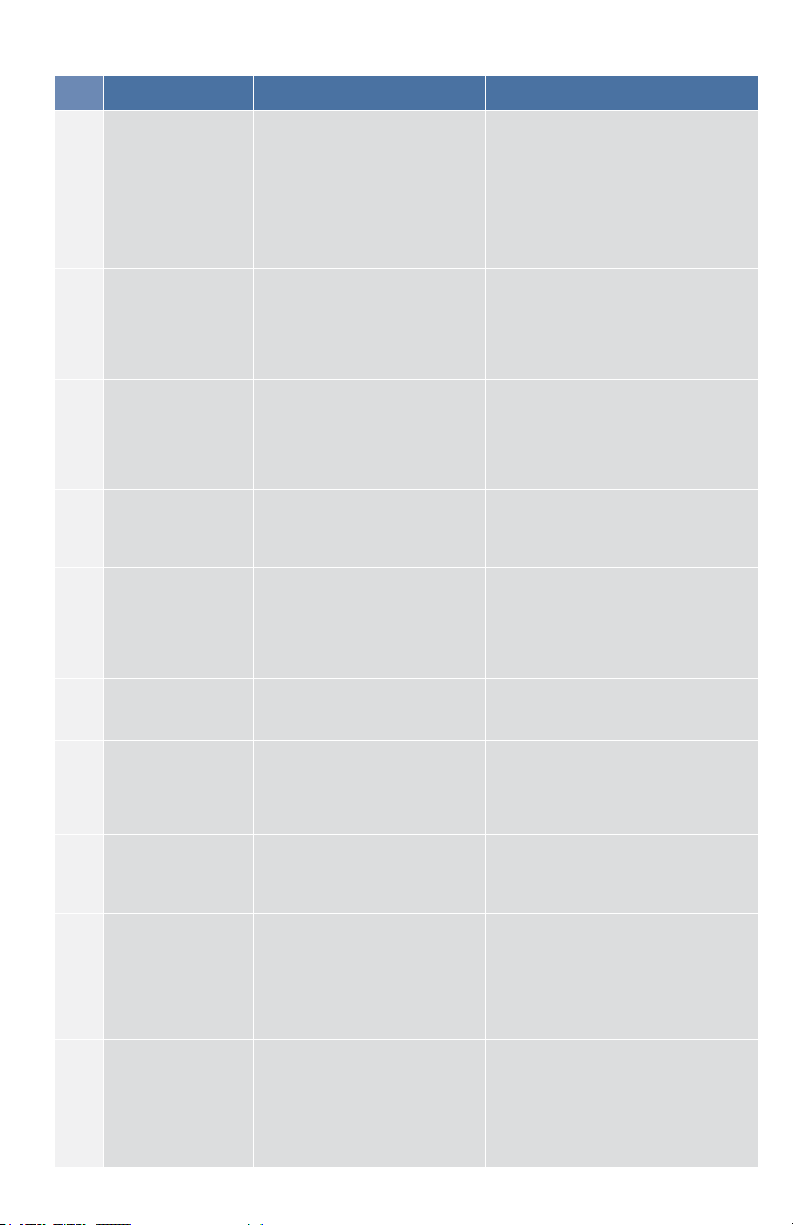

n153

Velocity limit

violation,

exceeding max

limit.

A new target velocity

calculated internally due to an

exception, and is being limited

due to user velocity limit.

Activation of any new motion or

using of DRV.CLRFAULTS will

clear the warning. Check motion

task target velocity settings and

parameters to make sure that the

values entered will not exceed the

VL.LIMITP and VL.LIMITN setting.

n154

Following motion

failed; check

motion parameters.

Activation of the following

motion task failed due to

incompatible parameters, or

motion task does not exist.

Activation of any new motion or

using of DRV.CLRFAULTS will clear

the warning. Check following motion

task settings and parameters to

make sure that the values entered

will produce a valid motion task.

6