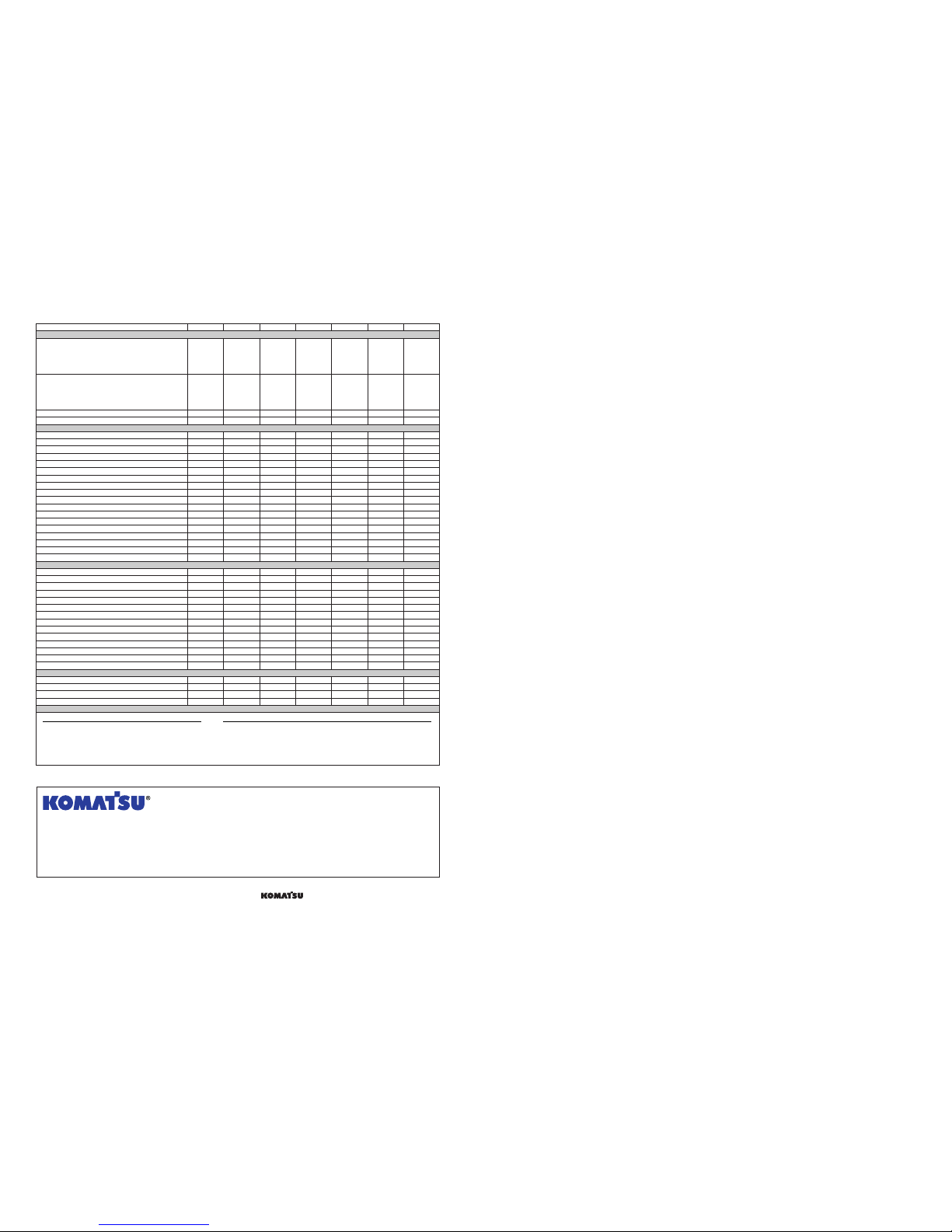

䢇: Standard equipment 嘷: Optional equipment

PC55MR-3PC45MR-3PC35MR-3PC30MR-3

Arm

PC27MR-3

STD arm with aux. piping

PC27MR: 1100mm 3'7" PC30MR: 1240mm 4'1"

PC18MR: 965mm 3'2" PC20MR: 970mm 3'2"

PC35MR: 1370mm 4'6" PC45MR: 1375mm 4'6"

Long arm with aux. piping

PC27MR: 1410mm 4'8" PC30MR: 1610mm 5'3"

PC18MR: 1215mm 4'0" PC20MR: 1320mm 4'4"

PC35MR: 1720mm 5'8" PC45MR: 1770mm 5'10"

STD arm without aux. piping

Long arm without aux. piping

Bucket Capacity Bucket width (incl. side cutters)

0.035m30.046yd3250mm 10" (320mm 13")

0.044m30.058yd3280mm 11" (350mm 14")

0.04m30.052yd3350mm 14" (400mm 16")

0.055m30.072yd3350mm 14" (420mm 17")

0.044m30.058yd3400mm 16" (450mm 18")

0.055m30.072yd3300mm 12" (370mm 14")

0.09m30.12yd3430mm 17" (500mm 20")

0.11m30.14yd3530mm 21" (600mm 24")

0.11m30.14yd3430mm 17" (500mm 20")

0.13m30.17yd3630mm 25" (700mm 28")

0.14m30.18yd3535mm 21" (600mm 24")

0.16m30.21yd3585mm 23" (650mm 26")

Track shoes

300mm 12" rubber shoes

400mm 16" rubber shoes

300mm 12" steel shoes

400mm 16" steel shoes

300mm 12" steel shoes with rubber pad

400mm 16" steel shoes with rubber pad

300mm 12" road liner

400mm 16" road liner

Blade

Blade assembly

Expandable blade assembly

Blade assembly with BOC

PAT blade

PC55MR: 1640mm 5'5"

PC55MR: 2000mm 6'7"

PC20MR-3PC18MR-3

0.033m30.043yd3250mm 10" (320mm 13")

0.022m30.029yd3300mm 12" (350mm 14")

0.044m30.058yd3350mm 14" (420mm 17")

0.066m30.086yd3430mm 17" (500mm 20")

250mm 10" rubber shoes

250mm 10" steel shoes

230mm 9" steel shoes

250mm 10" steel shoes with rubber pad

230mm 9" steel shoes with rubber pad

0.08m30.10yd3430mm 17" (500mm 20")

230mm 9" rubber shoes

0.08m30.10yd3530mm 21" (600mm 24")

Others

Standard equipment

• Additional counterweight

(PC18MR-3 and PC20MR-3)

• Air cleaner, single element

• Automatic two-speed travel

• Rear view mirrors, RH and LH

• Seat belt, 78mm 3" width

Optional equipment

• Additional working light

• Air conditioner (for cab)

(not available for PC18MR-3 and PC20MR-3)

• Cigarette lighter (for cab)

• Pattern change valve (ISO - Backhoe)

• Radiator net

• Radio (for cab)

• Steering pedals

• Rigid seat, reclining

with arm rests

• Travel alarm

• Two-post ROPS & Top

guard canopy

• Suspension seat, reclining with arm rests

• ROPS & Top guard cab

with heater, front window

washer/wiper,

cup holder and ashtray

(not available for PC18MR-3)

• Seat belt, 50mm 2" width

䢇䢇䢇䢇

嘷嘷嘷嘷

嘷嘷嘷嘷

嘷嘷嘷嘷

嘷

嘷

嘷

嘷嘷

嘷

䢇

䢇

嘷

嘷嘷

嘷

䢇

䢇

嘷

䢇䢇

䢇䢇

嘷嘷

嘷嘷

嘷嘷

嘷嘷

嘷嘷

嘷嘷

䢇䢇䢇䢇

嘷嘷嘷嘷

嘷嘷嘷嘷

䢇

嘷

嘷

嘷

嘷

嘷

嘷

䢇

嘷

嘷

嘷

䢇

嘷

䢇䢇

嘷

嘷

嘷

嘷

嘷

䢇

䢇

嘷

嘷

䢇

嘷

䢇

嘷

嘷

嘷

嘷

嘷

嘷

䢇

䢇

䢇

嘷

嘷