10 11

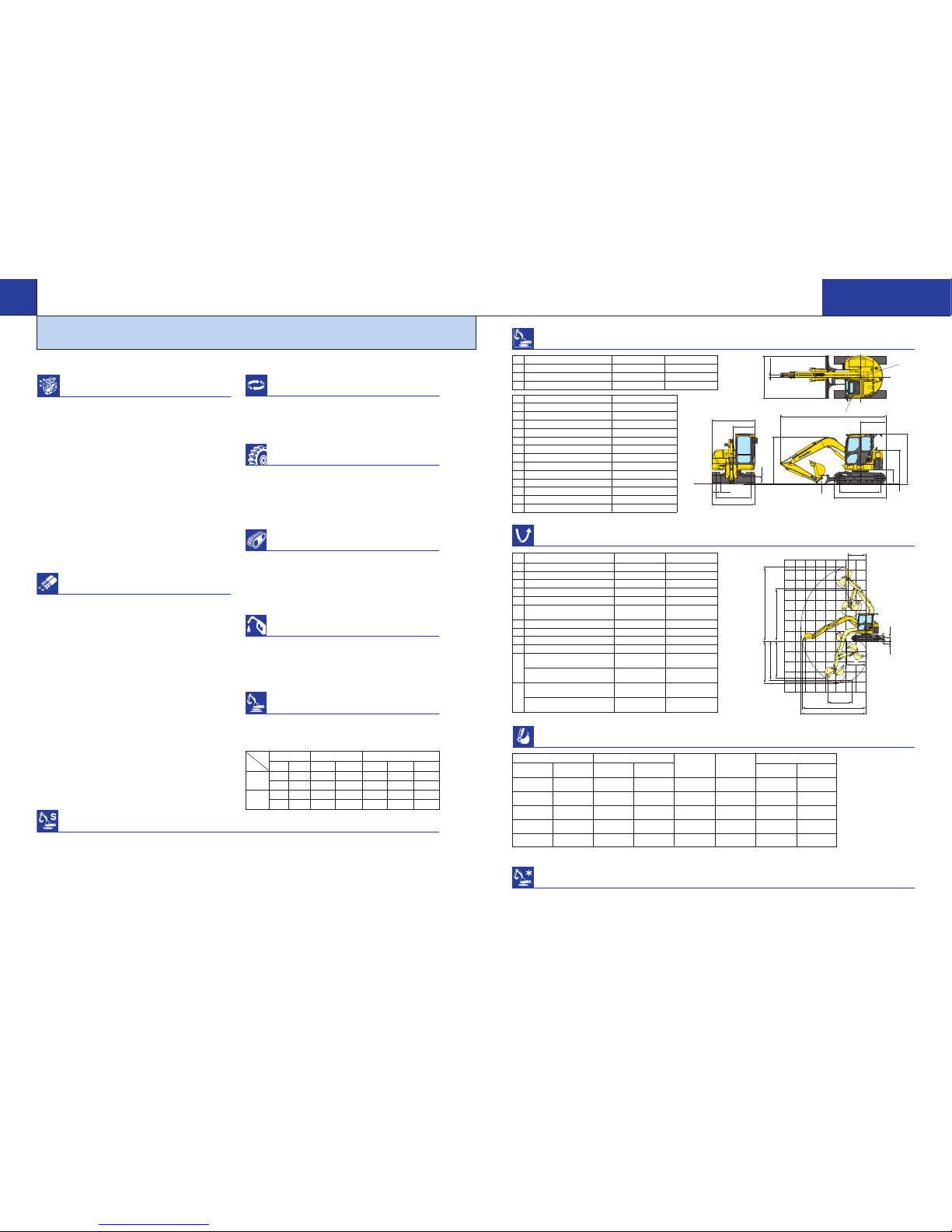

WORKING RANGE

DIMENSIONS

BACKHOE BUCKET AND ARM COMBINATION

SPECIFICATIONS

PC78US-8

Bucket Capacity (heaped)

Width Number Arm Length

SAE, PCSA

CECE

Without Side

With Side Weight 1650 mm 2250 mm

Cutters Cutters of Teeth 5'5" 7'5"

0.09 m30.08 m3350 mm 450 mm 145 kg 3

0.12 yd30.10 yd314" 18" 320 lb

0.12 m30.11 m3450 mm 550 mm 160 kg 3

0.16 yd30.14 yd318" 22" 355 lb

0.20 m30.18 m3550 mm 650 mm 185 kg 3

0.26 yd30.24 yd322" 26" 410 lb

0.28 m30.25 m3650 mm 750 mm 210 kg 4X

0.37 yd30.33 yd326" 30" 465 lb

0.34 m30.30 m3755 mm 210 kg 4□X

0.45 yd30.39 yd329.7" NA 465 lb

—General digging —Light-duty operation X— Not available

Shoes Operating Weight Ground Pressure

mm in kg lb kPa kg/cm2psi

With 450 17.7" 7365 16,240 33.0 0.34 4.83

blade 600 23.6" 7535 16,615 25.3 0.26 3.70

without 450 17.7" 6945 15,315 31.1 0.32 4.51

blade 600 23.6" 7115 15,690 23.9 0.24 3.47

ENGINE

Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Komatsu SAA4D95LE-5

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Water-cooled, 4-cycle

Aspiration . . . . . . . . . . . . . . Turbocharged, and air-to-air aftercooled

Number of cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Bore x stroke . . . . . . . . . . . . . . . . . . 95 mm x 115 mm 3.74" x 4.53"

Piston displacement. . . . . . . . . . . . . . . . . . . . . . . . . . 3.26 ltr 199 in3

Governor . . . . . . . . . . . . . . . . . . . . . . . . All-speed control, electronic

Horsepower

SAE J1995 . . . . . . . . . . . . . . . . . . . . . . . . . Gross 42.8 kW 57 HP

ISO 9249 / SAE J1349 . . . . . . . . . . . . . . . . . . . Net 41 kW 55 HP

Rated rpm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1950 rpm

Fuel system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Direct injection

Lubrication system

Method . . . . . . . . . . . . . . . . . . . . . . . Gear pump, force-lubrication

Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Full-flow

Air cleaner . . . . . . . . . . . . . . . . . . . . . Dry-type with double elements

. . . . . . . . . . . . . . . . . and auto dust evacuator, plus dust indicator

EPA Interim Tier 4 and EU Stage 3A emissions certified

Starting motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.5 kW/24 V

Alternator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35 A/24 V

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55 Ah/2 x 12 V

HYDRAULICS SYSTEM

Type . . . . . . . . . . . . . . . . . . . . . . HydrauMind (Hydraulic Mechanical

Intelligence New Design) system,

Closed-center system with load-sensing valve

and pressure-compensated valve

Main pumps:

Type . . . . . . . . . . . . . . . . . . . . Variable displacement, axial piston

Maximum flow . . . . . . . . . . . . . . . . 160 ltr/min 42.3 U.S. gal/min

Type (for machine with blade) . . . . . . . . . Fixed displacement gear

Maximum flow . . . . . . . . . . . . . . . . . 63 ltr/min 16.6 U.S. gal/min

Hydraulic motors:

Travel . . . . . . . . . . . . . . . . . . . 2 x piston motor with parking brake

Swing . . . . . . . . . . . . . . 1 x piston motor with swing holding brake

Relief valve setting:

Implement, travel circuit . . . . . . 26.5 MPa 270 kgf/cm23,840 psi

Swing circuit. . . . . . . . . . . . . . . 20.6 MPa 210 kgf/cm22,990 psi

Blade circuit (Raise) . . . . . . . . . 12.7 MPa 130 kgf/cm21,850 psi

(Lower) . . . . . . . . 21.1 MPa 215 kgf/cm23,060 psi

Hydraulic cylinders:

(Number of cylinders – bore x stroke x rod diameter)

Boom . . . . . . . 1–115 mm x 858 mm x 65 mm 4.5" x 33.8" x 2.6"

Arm . . . . . . . . 1–100 mm x 861 mm x 60 mm 3.9" x 33.9" x 2.4"

Bucket . . . . . . 1– 90 mm x 710 mm x 55 mm 3.5" x 28.0" x 2.2"

Blade . . . . . . . 1–130 mm x 130 mm x 65 mm 5.1" x 5.1" x 2.6"

SWING SYSTEM

Driven by . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Hydraulic motor

Swing reduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Planetary gear

Swing circle lubrication . . . . . . . . . . . . . . . . . . . . . . . Grease-bathed

Swing lock . . . . . . . . . . . . . . . . . . . . . . . . . . . Mechanical disc brake

Swing speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 rpm

DRIVES AND BRAKES

Steering control . . . . . . . . . . . . . . . . . . . . . . . Two levers with pedals

Drive method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Hydrostatic

Maximum drawbar pull. . . . . . . . . . . . . . 66.9 kN 6820 kgf 15,050 lbf

Maximum travel speed: High . . . . . . . . . . . . . . . . . 5.0 km/h 3.1 mph

Low . . . . . . . . . . . . . . . . . 2.9 km/h 1.8 mph

Service brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Hydraulic lock

Parking brake. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Mechanical disc

UNDERCARRIAGE

Center frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X-frame

Track frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Box-section

Seal of track . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Sealed track

Track adjuster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Hydraulic

Number of shoes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39 each side

Number of carrier rollers . . . . . . . . . . . . . . . . . . . . . . . . . 1 each side

Number of track rollers . . . . . . . . . . . . . . . . . . . . . . . . . . 5 each side

COOLANT AND LUBRICANT

CAPACITY (REFILLING)

Fuel tank . . . . . . . . . . . . . . . . . . . . . . . . 125 ltr 33.0 U.S. gal

Radiator . . . . . . . . . . . . . . . . . . . . . . . . . . 10 ltr 2.6 U.S. gal

Engine. . . . . . . . . . . . . . . . . . . . . 11.5 (11.0) ltr 3.0 (2.9) U.S. gal

Final drive, each side . . . . . . . . . . . . . . . 1.1 ltr 0.3 U.S. gal

Swing drive . . . . . . . . . . . . . . . . . . . . . . . 2.0 ltr 0.5 U.S. gal

Hydraulic tank . . . . . . . . . . . . . . . . . 100 (56) ltr 26.4 (14.8) U.S. gal

OPERATING WEIGHT (APPROXIMATE)

Operating weight including 3710 mm 12'2" one-piece boom,

1650 mm 5'5" arm, SAE heaped 0.28 m30.37 yd3backhoe bucket,

blade, rated capacity of lubricants, coolant, full fuel tank, operator,

and standard equipment.

Boom Length 3710 mm 12'2" 3710 mm 12'2"

Arm Length 1650 mm 5'5" 2250 mm 7'5"

AOverall length 5770 mm 18'11" 6295 mm 20'8"

BOverall height (to top of boom)* 2555 mm 8'5" 2870 mm 9'5"

COverall width 2330 mm 7'8"

DOverall height (to top of cab)* 2730 mm 8'11"

EGround clearance, counterweight 735 mm 2'5"

FMinimum ground clearance 360 mm 1'2"

GTail swing radius 1240 mm 4'1"

HLength of track on ground 2235 mm 7'4"

ITrack length 2840 mm 9'4"

JTrack gauge 1870 mm 6'2"

KWidth of crawler 2320 mm 7'7"

LShoe width 450 mm 17.7"

MGrouser height 20 mm 0.8"

NMachine cab height 1835 mm 6'0"

OMachine cab width 2330 mm 7'8"

PDistance swing center to rear end 1405 mm 4'7"

Boom Length

3710 mm 12'2" 3710 mm 12'2"

Arm

Length

1650 mm 5'5" 2250 mm 7'5"

AMaximum digging height 7300 mm 23'11" 7600 mm 24'11"

BMaximum dumping height 5180 mm 17'0" 5500 mm 18'1"

CMaximum digging depth 4100 mm 13'5" 4710 mm 15'5"

DMaximum vertical wall digging depth 3610 mm 11'10" 4030 mm 13'3"

EMaximum digging depth of cut for

2440 mm 8' level 3770 mm 12'4" 4430 mm 14'6"

FMaximum digging reach 6380 mm 20'11" 6920 mm 22'8"

GMaximum digging reach at ground 6240 mm 20'6" 6790 mm 22'3"

HMinimum digging reach at ground 1900 mm 6'3" 1735 mm 5'8"

IMinimum swing radius 1750 mm 5'9" 2050 mm 6'9"

ISO Bucket digging force 61.3 kN 61.3 kN

6250 kgf 13,780 lbf 6250 kgf 13,780 lbf

Arm crowd force 41.5 kN 34.5 kN

4230 kgf 9,330 lbf 3520 kgf 7,760 lbf

SAE Bucket digging force 53.3 kN 53.3 kN

5440 kgf 11,990 lbf 5440 kgf 11,990 lbf

Arm crowd force 38.1 kN 33.1 kN

3890 kgf 8,570 lbf 3380 kgf 7,450 lbf