TABLE OF CONTENTS

FOREWORD.................................................................................................................................................... 1-1

READ THIS MANUAL............................................................................................................................... 1-2

SAFETY INFORMATION .......................................................................................................................... 1-3

INTRODUCTION ...................................................................................................................................... 1-4

MAIN USE OF MACHINE .................................................................................................................. 1-4

DIRECTIONS OF MACHINE.............................................................................................................. 1-4

VISIBILITY FROM OPERATOR'S SEAT ............................................................................................ 1-4

ENGINE TECHNOLOGY TO CONFORM EXHAUST GAS EMISSION..................................................... 1-5

PRODUCT INFORMATION....................................................................................................................... 1-6

LOCATION OF PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE ........ 1-6

LOCATION OF ENGINE NUMBER PLATE ........................................................................................ 1-6

SERVICE METER LOCATION........................................................................................................... 1-7

YOUR MACHINE SERIAL NUMBERS AND DISTRIBUTOR.............................................................. 1-7

SAFETY........................................................................................................................................................... 2-1

SAFETY.................................................................................................................................................... 2-2

SAFETY LABELS ..................................................................................................................................... 2-4

LOCATION OF SAFETY LABELS...................................................................................................... 2-5

CONTENTS OF SAFETY LABELS .................................................................................................... 2-7

GENERAL PRECAUTIONS COMMON TO OPERATION AND MAINTENANCE .................................... 2-15

PRECAUTIONS BEFORE STARTING OPERATION........................................................................ 2-15

PREPARATIONS FOR SAFE OPERATION ..................................................................................... 2-15

PRECAUTIONS TO PREVENT FIRE............................................................................................... 2-16

PRECAUTIONS WHEN GETTING ON OR OFF MACHINE............................................................. 2-18

DO NOT GET CAUGHT................................................................................................................... 2-20

PRECAUTIONS RELATED TO PROTECTIVE STRUCTURES........................................................ 2-21

UNAUTHORIZED MODIFICATION .................................................................................................. 2-21

PRECAUTIONS RELATED TO ATTACHMENTS AND OPTIONS .................................................... 2-21

PRECAUTIONS WHEN RUNNING ENGINE INSIDE BUILDING..................................................... 2-21

PRECAUTIONS FOR OPERATION ........................................................................................................ 2-22

PRECAUTIONS FOR JOBSITE....................................................................................................... 2-22

START ENGINE............................................................................................................................... 2-24

PRECAUTIONS FOR OPERATION ................................................................................................. 2-26

PRECAUTIONS FOR TRANSPORTATION...................................................................................... 2-31

TOWING AND BEING TOWED........................................................................................................ 2-32

PRECAUTIONS FOR MAINTENANCE................................................................................................... 2-33

PRECAUTIONS BEFORE STARTING INSPECTION AND MAINTENANCE ................................... 2-33

PRECAUTIONS FOR CHECK AND MAINTENANCE ...................................................................... 2-36

TIRES .............................................................................................................................................. 2-41

PRECAUTIONS FOR DEF...................................................................................................................... 2-42

GENERAL CHARACTER AND PRECAUTIONS FOR HANDLING .................................................. 2-42

PRECAUTIONS FOR ADDING........................................................................................................ 2-42

PRECAUTIONS FOR STORING...................................................................................................... 2-42

PRECAUTIONS FOR FIRE HAZARD AND LEAKAGE .................................................................... 2-42

OTHER PRECAUTIONS.................................................................................................................. 2-42

OPERATION .................................................................................................................................................... 3-1

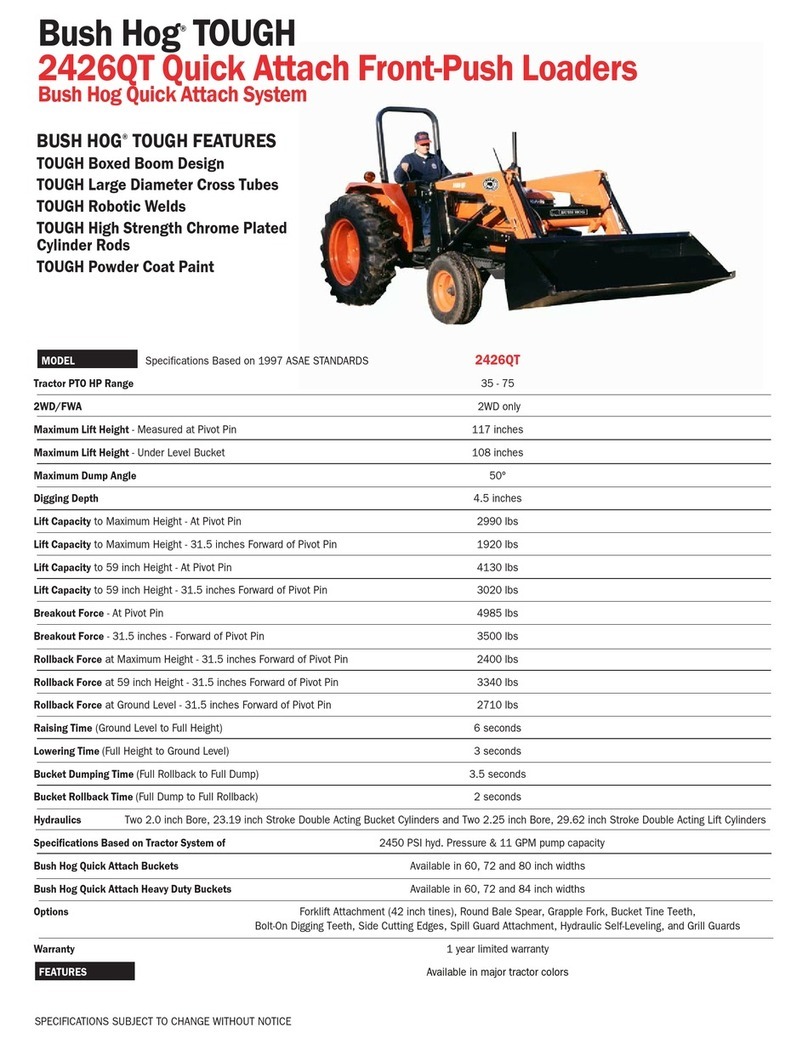

GENERAL VIEW....................................................................................................................................... 3-2

MACHINE EQUIPMENT NAME ......................................................................................................... 3-2

CONTROLS AND GAUGES NAMES................................................................................................. 3-3

OTHER EQUIPMENT NAME............................................................................................................. 3-7

EXPLANATION OF COMPONENTS....................................................................................................... 3-10

EXPLANATION OF MACHINE MONITOR EQUIPMENT ................................................................. 3-10

SWITCHES...................................................................................................................................... 3-89

CONTROL LEVERS AND PEDALS............................................................................................... 3-104

OTHER EQUIPMENT .................................................................................................................... 3-108

MACHINE OPERATIONS AND CONTROLS ........................................................................................ 3-147

CHECKS AND ADJUSTMENT BEFORE STARTING ENGINE ...................................................... 3-147

TABLE OF CONTENTS FOREWORD

1-8

Find manuals at https://best-manuals.com