10 11

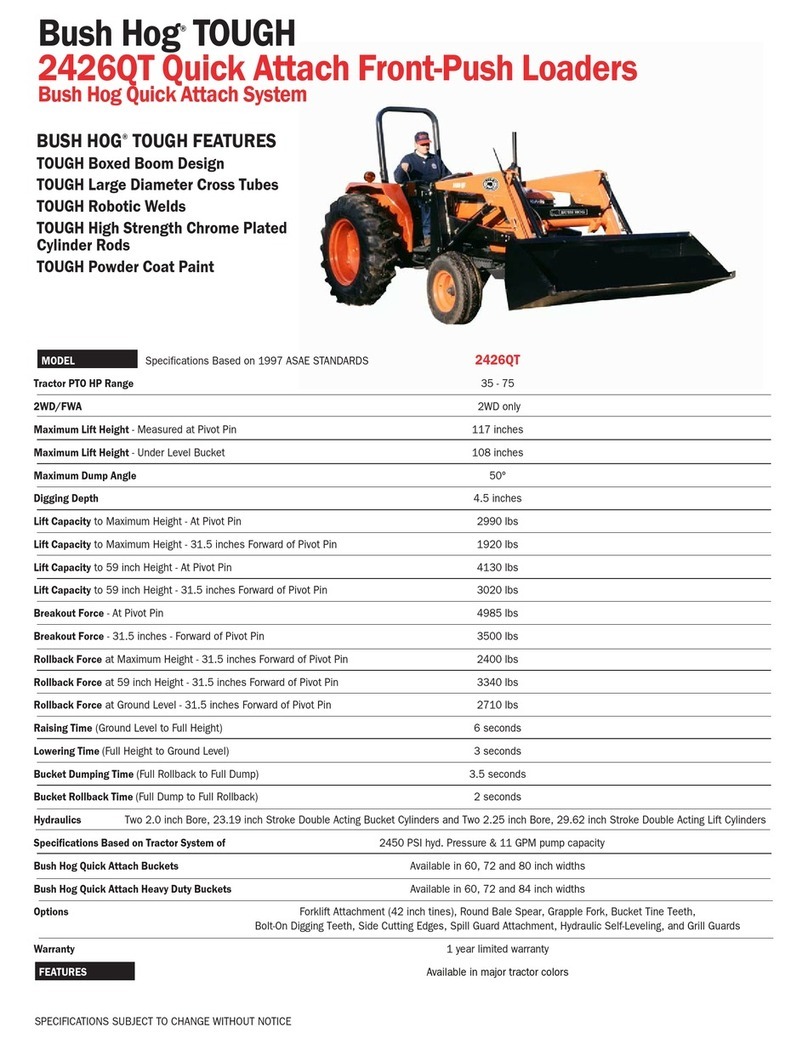

SPECIFICATIONS

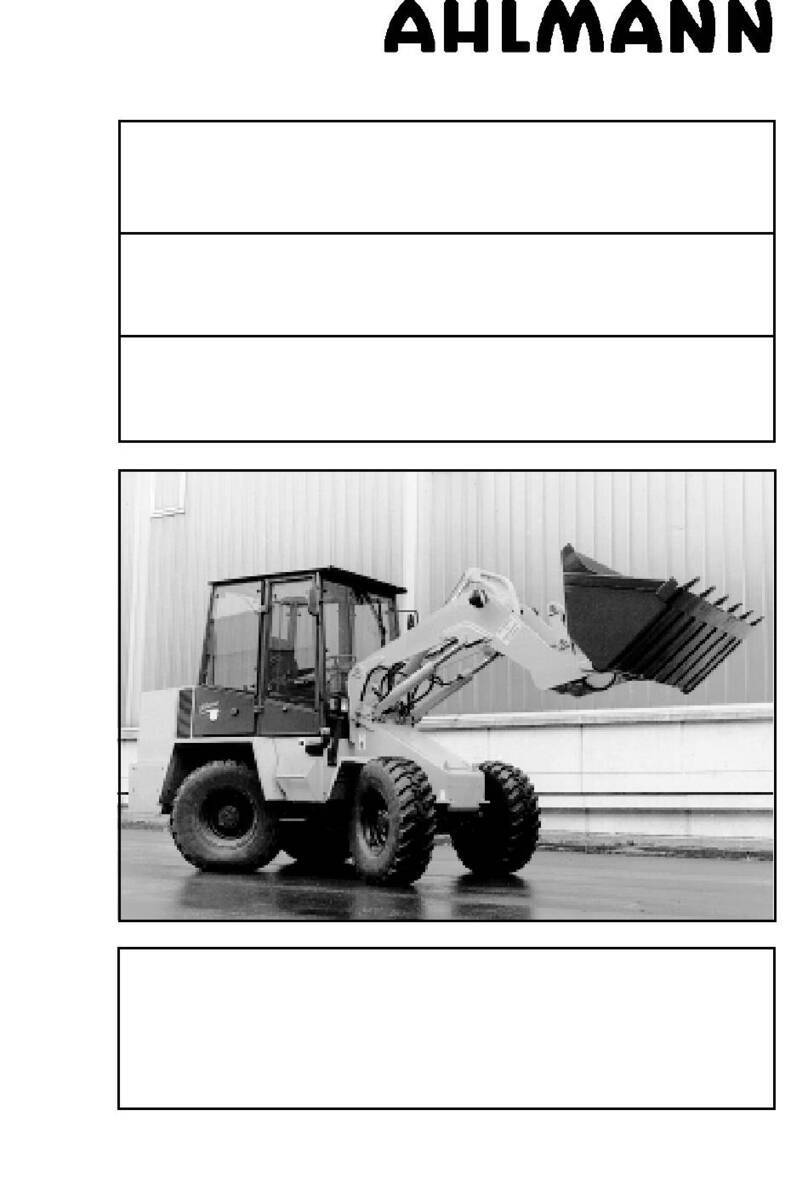

WHEEL LOADER

WA900-3E0 WHEEL LOADER

AXLES AND FINAL DRIVES

Drive system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Four-wheel drive

Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Fixed, full-floating

Rear . . . . . . . . . . . . . . . . . . . . . . . . .Center-pin support, full-floating,

22

˚

total oscillation

Reduction gear . . . . . . . . . . . . . . . . . . . . . . . . . . . .Spiral bevel gear

Differential gear . . . . . . . . . . . . . . . . . . . . . . . . . .Straight bevel gear

Final reduction gear . . . . . .Planetary gear, single reduction, oil bath

BRAKES

Service brakes . . . . . . . . . . . . . . . . . . . . . . . .Hydraulically actuated,

wet disc brakes actuate on four wheels

Parking brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Dry disc brake

Emergency brake . . . . . . . . . . . . . .Parking brake is commonly used

1st 2nd 3rd

Forward 7.0 4.3 12.3 7.6 28.0 17.4

Reverse 7.1 4.4 12.4 7.7 28.3 17.6

ENGINE

Model . . . . . . . . . . . . . . . . . . . . . . . . . . . .Komatsu SAA12V140E-3

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Water-cooled, 4-cycle

Aspiration . . . . . . . . . . . . . . . . . .Turbocharged, air-to-air aftercooled

Number of cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Bore x stroke . . . . . . . . . . . . . . . . .140 mm x 165 mm 5.51" x 6.50"

Piston displacement . . . . . . . . . . . . . . . . . . . . . . .30.48 ltr 1860 in3

Governor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .all-speed, electronic

Flywheel horsepower

SAE J1995 . . . . . . . . . . . . . . . . . . . . . . . . .Gross 672 kW 900 HP

ISO 9249/SAE J1349 . . . . . . . . . . . . . . . . . . .Net 638 kW 856 HP

Rated rpm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2050 rpm

Fan drive method for radiator cooling . . . . . . . . . . . . . . . .Mechanical

Fuel system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Direct injection

Lubrication system:

Method . . . . . . . . . . . . . . . . . . . . . . . .Gear pump, force-lubrication

Filter . . . . . . . . . . . . . . . . . . . . . . . Full-flow and bypass combined

Air cleaner . . . . . . . . . . . . . . . . .Dry type with automatic dust ejector

and pre-cleaner, cyclopac with vacuator

TRANSMISSION

Torque converter:

Type . . . . . . . . . . . . . . . . . . . .3-element, single-stage, single-phase

Transmission:

Type . . . . . . . . . . . . . . . . . . . . . . . . .Full-powershift, planetary type

Travel speed: km/h mph

Measured with 45/65-45-58 tires

HYDRAULIC SYSTEM

Steering system:

Hydraulic pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Piston pump

Capacity . . . . . . . . . . . .315 ltr/min 83.2 U.S. gal/min at rated rpm

Relief valve setting . . . . . . . . . . . .34.3 MPa 350 kgf/cm24,977 psi

Hydraulic cylinders:

Type . . . . . . . . . . . . . . . . . . . . . . . . . .Double-acting, piston type

Number of cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Bore x stroke . . . . . . . . . . . . . .160 mm x 503 mm 6.3" x 19.8"

Loader control:

Hydraulic pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Piston pump

Capacity . . . . . . . . . . . . . . . . . . . . .415 ltr/min 109.6 U.S. gal/min

at rated rpm

Relief valve setting . . . . . . . . . . . .34.3 MPa 350 kgf/cm24,977 psi

Hydraulic cylinders:

Type . . . . . . . . . . . . . . . . . . . . . . . . . .Double-acting, piston type

Number of cylinders—bore x stroke:

Boom cylinder . . . . . . . . .2- 260 mm x 1368 mm 10.2" x 53.9"

Bucket cylinder . . . . . . . . . .1- 300 mm x 906 mm 11.8" x 35.7"

Control valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Spool type

Control positions:

Boom . . . . . . . . . . . . . . . . . . . . . . . .Raise, hold, lower, and float

Bucket . . . . . . . . . . . . . . . . . . . . . . . . .Tilt-back, hold, and dump

Hydraulic cycle time (rated load in bucket)

Raise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11.2 sec

Dump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.0 sec

Lower (Empty) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4.8 sec

ROPS / FOPS & CAB

Structure complies with ISO 3471 ROPS (Roll-Over Protective

Structure) standards, as well as ISO 3449 FOPS (Falling Object

Protective Structure) standards. The cab is mounted on rubber pads

and is well insulated.

SERVICE REFILL CAPACITIES

Cooling system . . . . . . . . . . . . . . . . . . . . . . . .337 ltr 89.0 U.S. gal

Fuel tank . . . . . . . . . . . . . . . . . . . . . . . . . . . .1555 ltr 410.8 U.S. gal

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .130 ltr 34.3 U.S. gal

Hydraulic system . . . . . . . . . . . . . . . . . . . . . . .725 ltr 191.5 U.S. gal

Axle (each front and rear) . . . . . . . . . . . . . . . .360 ltr 95.1 U.S. gal

Torque converter and transmission . . . . . . . . .140 ltr 37.0 U.S. gal

BUCKET SELECTION GUIDE

STEERING SYSTEM

Type . . . . . . . . . . . . . . .Articulated type, full-hydraulic power steering

Steering angle . . . . . . . . . . . . . . . . . . . . . . . . . . .40

˚

each direction

Minimum turning radius at

the center of outside tire . . . . . . . . . . . . . . . . . . . . . .9200 mm 30'2"

Standard boom

High lift boom

Excavating Bucket Excavating Bucket

Spade nose Spade nose

Tipteeth teeth

Bucket capacity: heaped 13.0 m311.5 m3

17.0 yd315.0 yd3

struck 11.0 m39.7 m3

14.4 yd312.7 yd3

Bucket width 4810 mm 4810 mm

15'9" 15'9"

Bucket weight 12330 kg 11370 kg

27,180 lb 25,070 lb

Dumping clearance, max. height 4640 mm 5255 mm

and 45˚dump angle 15'3" 17'3"

Reach at max. height and 45˚dump angle 2450 mm 2235 mm

8' 7'4"

Reach at 2130 mm (7') clearance 3650 mm 4020 mm

and 45˚dump angle 12' 13'2"

Reach with arm horizontal and bucket level 4640 mm 4760 mm

15'3" 15'7"

Operating height (fully raised) 9680 mm 9875 mm

31'9" 32'5"

Overall length 14490 mm 14685 mm

47'6" 48'2"

Loader clearance circle (bucket at carry, 22000 mm 22200 mm

outside corner of bucket) 72'2" 72'10"

Digging depth: 0˚165 mm 160 mm

6.5" 6.3"

10˚645 mm 610 mm

2'1" 2'0"

Static tipping load: straight 65670 kg 62540 kg

144,780 lb 137,880 lb

40˚full turn 57430 kg 55030 kg

126,610 lb 121,320 lb

Breakout force 666 kN 703 kN

67900 kgf 71700 kgf

149,690 lb 158,070 lb

Operating weight 107200 kg 107350 kg

236,340 lb 236,670 lb

DIMENSIONS

All dimensions, weights, and performance values based on SAE J732c and J742b standards.

Static tipping load and operating weight shown include lubricant, coolant, full fuel tank, ROPS canopy, air conditioner, bucket and operator. Machine stability and

operating weight are affected by counterweight, or ballast, tire size, and other attachments.

Use either counterweight or ballast, not both. Apply the following weight changes to operating weight and static tipping load.

Measured with 45/65-45-58PR(L-5) tires

WA900-3E0

Standard High lift

Boom Boom

Tread 3350 mm 11'

Width over tires 4585 mm 15'1"

A Wheelbase 5450 mm 17'11"

B Hinge pin height, max. height

6960 mm 22'10" 7445 mm 24'5"

C Hinge pin height, carry position

800 mm 2'7"

D Ground clearance 550 mm 1'10"

E Hitch height 1390 mm 4'7"

F Overall height, top of the stack 5130 mm 16'10"

G Overall height, ROPS cab 5275 mm 17'4"