TABLE OF CONTENTS

FOREWORD.................................................................................................................................................... 1-1

READ THIS MANUAL............................................................................................................................... 1-2

SAFETY INFORMATION .......................................................................................................................... 1-3

INTRODUCTION ...................................................................................................................................... 1-4

MAIN USE OF MACHINE .................................................................................................................. 1-4

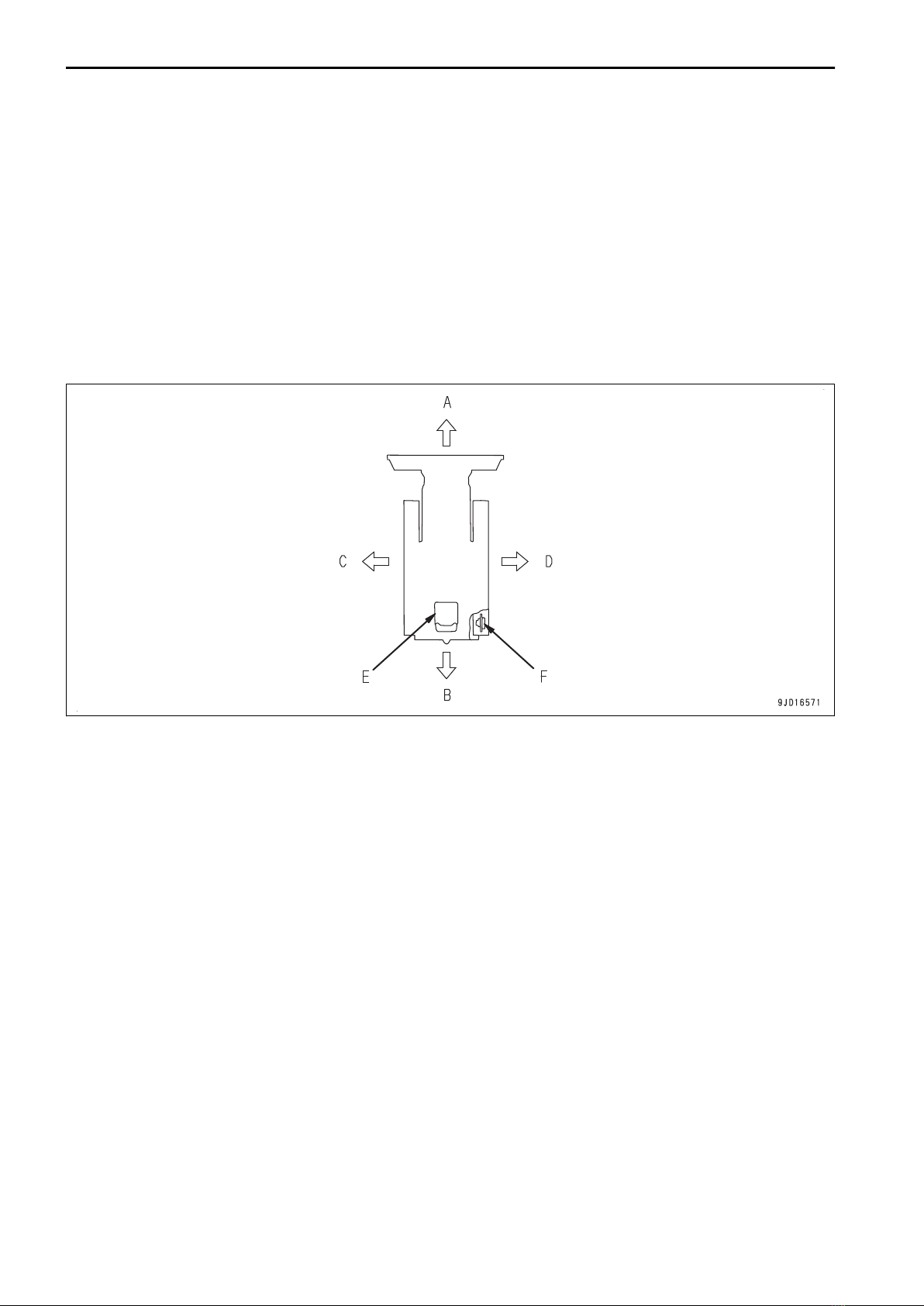

DIRECTIONS OF MACHINE.............................................................................................................. 1-4

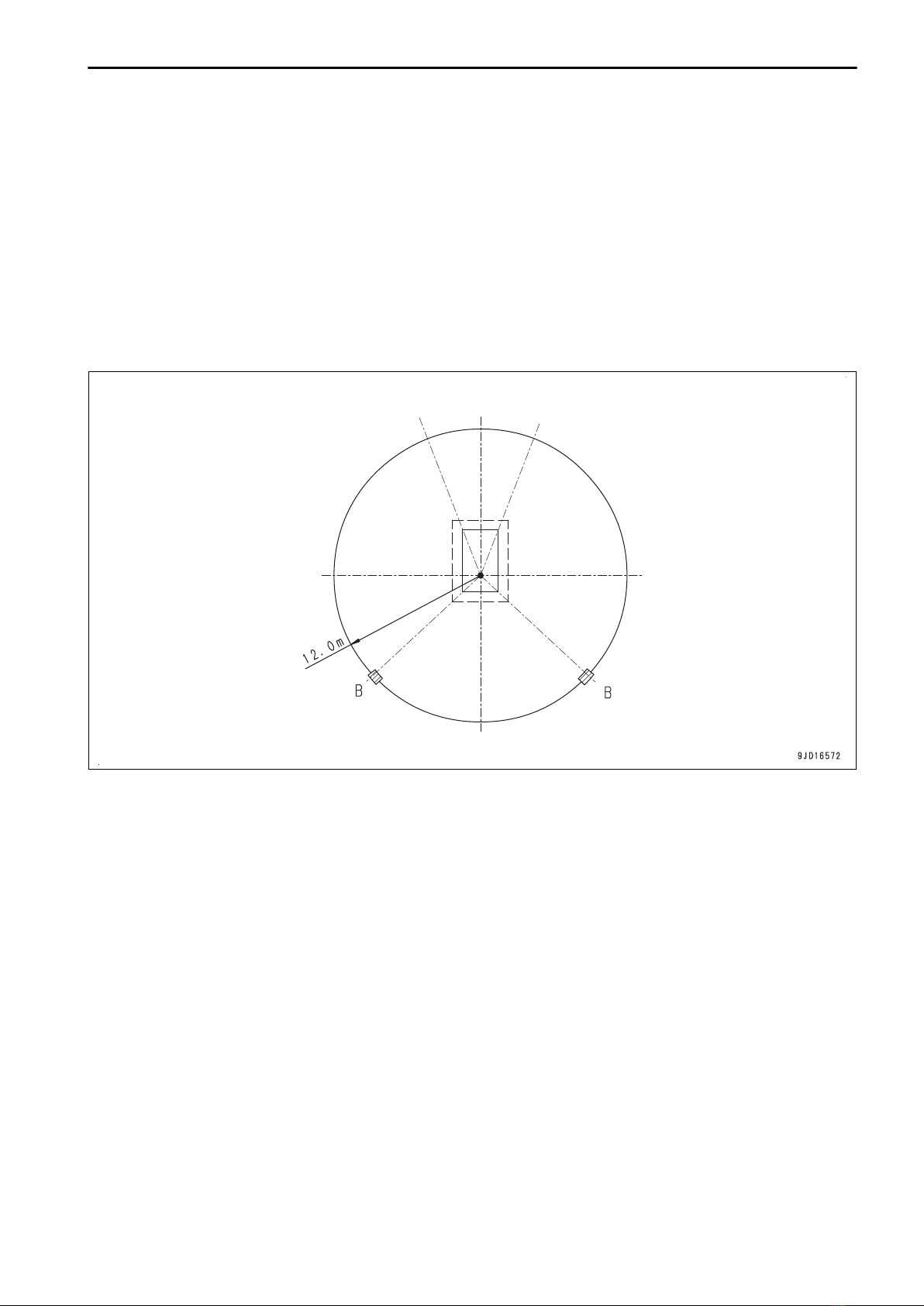

VISIBILITY FROM OPERATOR'S SEAT ............................................................................................ 1-5

ENGINE TECHNOLOGY TO CONFORM EXHAUST GAS EMISSION..................................................... 1-6

PRODUCT INFORMATION....................................................................................................................... 1-7

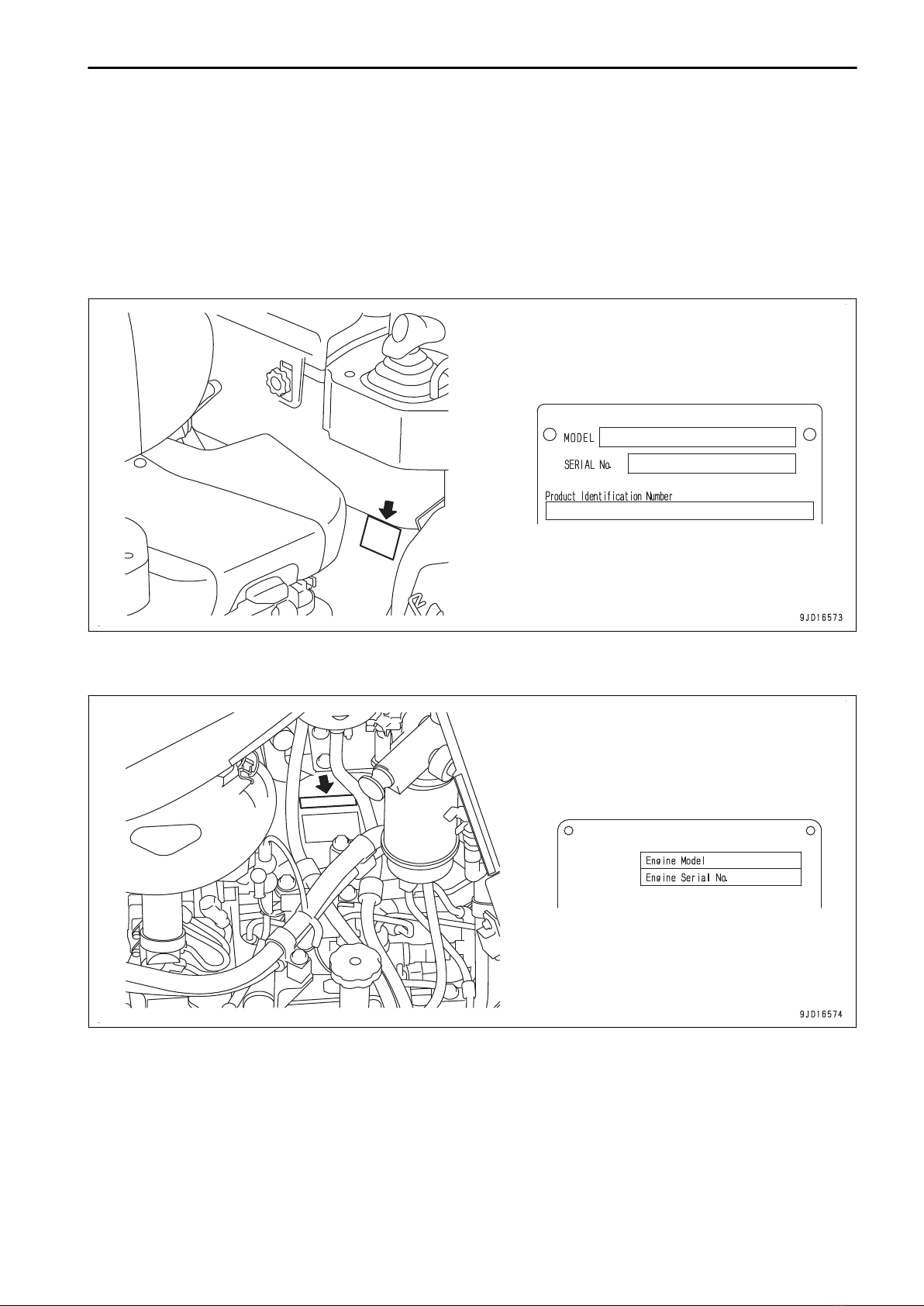

LOCATION OF PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE ........ 1-7

LOCATION OF ENGINE NUMBER PLATE ........................................................................................ 1-7

SERVICE METER LOCATION........................................................................................................... 1-8

YOUR MACHINE SERIAL NUMBERS AND DISTRIBUTOR.............................................................. 1-8

SAFETY........................................................................................................................................................... 2-1

SAFETY LABELS ..................................................................................................................................... 2-2

LOCATION OF SAFETY LABELS...................................................................................................... 2-3

CONTENTS OF SAFETY LABELS .................................................................................................... 2-4

GENERAL PRECAUTIONS COMMON TO OPERATION AND MAINTENANCE ...................................... 2-9

PRECAUTIONS BEFORE STARTING OPERATION.......................................................................... 2-9

PREPARATIONS FOR SAFE OPERATION ....................................................................................... 2-9

PRECAUTIONS TO PREVENT FIRE................................................................................................2-11

PRECAUTIONS WHEN GETTING ON OR OFF MACHINE............................................................. 2-13

DO NOT GET CAUGHT IN WORK EQUIPMENT ............................................................................ 2-14

PRECAUTIONS RELATED TO PROTECTIVE STRUCTURES........................................................ 2-15

UNAUTHORIZED MODIFICATION .................................................................................................. 2-15

PRECAUTIONS RELATED TO ATTACHMENTS AND OPTIONS .................................................... 2-15

PRECAUTIONS WHEN RUNNING ENGINE INSIDE BUILDING..................................................... 2-15

PRECAUTIONS FOR OPERATION ........................................................................................................ 2-16

PRECAUTIONS FOR JOBSITE....................................................................................................... 2-16

START ENGINE............................................................................................................................... 2-19

PRECAUTIONS FOR OPERATION ................................................................................................. 2-21

PRECAUTIONS FOR TRANSPORTATION...................................................................................... 2-25

TOWING AND BEING TOWED........................................................................................................ 2-26

PRECAUTIONS FOR MAINTENANCE................................................................................................... 2-27

PRECAUTIONS BEFORE STARTING INSPECTION AND MAINTENANCE ................................... 2-27

PRECAUTIONS FOR CHECK AND MAINTENANCE ...................................................................... 2-31

PRECAUTIONS FOR DEF...................................................................................................................... 2-37

GENERAL CHARACTER AND PRECAUTIONS FOR HANDLING .................................................. 2-37

PRECAUTIONS FOR ADDING........................................................................................................ 2-37

PRECAUTIONS FOR STORING...................................................................................................... 2-37

PRECAUTIONS FOR FIRE HAZARD AND LEAKAGE .................................................................... 2-37

OTHER PRECAUTIONS.................................................................................................................. 2-37

OPERATION.................................................................................................................................................... 3-1

GENERAL VIEW....................................................................................................................................... 3-2

MACHINE EQUIPMENT NAME ......................................................................................................... 3-2

CONTROLS AND GAUGES NAMES................................................................................................. 3-3

EXPLANATION OF COMPONENTS......................................................................................................... 3-5

EXPLANATION OF MACHINE MONITOR EQUIPMENT ................................................................... 3-5

SWITCHES...................................................................................................................................... 3-94

CONTROL LEVERS AND PEDALS............................................................................................... 3-100

OTHER EQUIPMENT .................................................................................................................... 3-107

MACHINE OPERATIONS AND CONTROLS ........................................................................................ 3-151

CHECKS AND ADJUSTMENT BEFORE STARTING ENGINE ...................................................... 3-151

METHOD FOR STARTING ENGINE.............................................................................................. 3-188

METHOD FOR OPERATIONS AND CHECKS AFTER STARTING ENGINE ................................. 3-193

METHOD FOR STOPPING ENGINE ............................................................................................. 3-197

FOREWORD TABLE OF CONTENTS

1-9