EN

This symbol indicates that this product is not to be disposed of with your household waste, according to the

WEEE Directive (2002/96/EC) and your national law. This product should be handed over to a designated

collection point, or to an authorised collection site for recycling waste electrical and electronic equipment (EEE). Im-

proper handling of this type of waste could have a possible negative impact on the environment and human health due

to potentially hazardous substances that are generally associated with EEE. At the same time, your cooperation in the

correct disposal of this product will contribute to the eective usage of natural resources. For more information about

where you can drop o your waste equipment for recycling, please contact your local city oce, waste authority, ap-

proved WEEE scheme or your household waste disposal service.

Content

1. ELECTRICAL INSTALLATION INSTRUCTIONS........................................................................................................................................3

1.1. Power supply connection...........................................................................................................................................................................3

1.2. Control panel installation...........................................................................................................................................................................3

1.3. Connection of external elements ...........................................................................................................................................................4

1.4. Temperature sensor installation...............................................................................................................................................................5

2. OPERATING MANUAL........................................................................................................................................................................................6

2.1. Unit control with the control panel ........................................................................................................................................................6

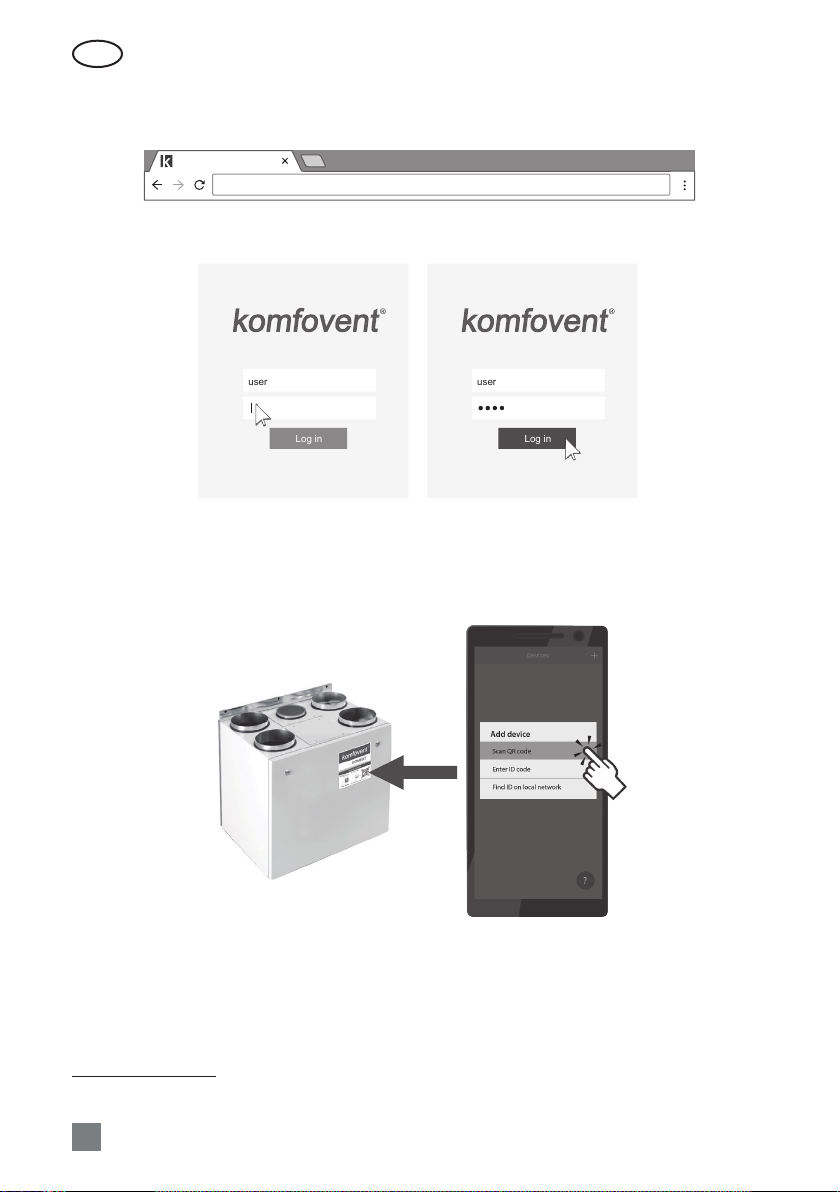

2.2. Connecting the unit to local computer network or the Internet.................................................................................................6

2.3. Unit control with a smartphone...............................................................................................................................................................8

2.4. Control Panel C6.1.........................................................................................................................................................................................9

2.4.1. Displayed symbols on the panel.................................................................................................................................................9

2.4.2. Review of the parameters .......................................................................................................................................................... 10

2.4.3. Operation mode selection......................................................................................................................................................... 10

2.4.4. ECO mode........................................................................................................................................................................................ 11

2.4.5. AUTO mode..................................................................................................................................................................................... 12

2.4.6. Menu.................................................................................................................................................................................................. 12

2.4.6.1. Overview ......................................................................................................................................................................... 12

2.4.6.2. Scheduling...................................................................................................................................................................... 13

2.4.6.3. Air quality........................................................................................................................................................................ 15

2.4.6.4. Settings............................................................................................................................................................................ 15

2.4.6.5. Advanced settings....................................................................................................................................................... 15

2.5. Control Panel C6.2...................................................................................................................................................................................... 20

2.5.1. Operating mode selection......................................................................................................................................................... 20

2.5.2.„ECO“.................................................................................................................................................................................................. 20

2.5.3. AUTO mode..................................................................................................................................................................................... 20

2.5.4. Warning indicator.......................................................................................................................................................................... 20

2.5.5. Reset button.................................................................................................................................................................................... 20

2.5.6. Turning the unit on/o................................................................................................................................................................ 20

2.5.7. Keypad lock..................................................................................................................................................................................... 21

2.5.8. Control panel alarm message sound signal enable / disable........................................................................................ 21

2.6. Troubleshooting.......................................................................................................................................................................................... 21

APENDIX NO.1. KOMFOVENT CONTROL Terms of Use and Privacy Notice.............................................................................. 24